Polyrix, the manufacturer of measurement solutions for industrial manufacturing companies, will focus on the PolyScan surround 3D scanner at Control (Hall 4 Booth 4203).

© Polyrix

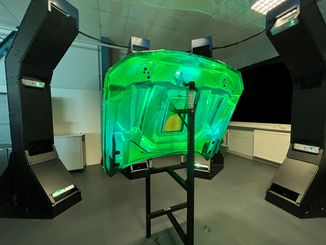

“PolyScan Surround 3D scanners are motionless, multi-sensory 3D measurement systems. This breakthrough scanning technology enables full three-dimensional acquisition of a wide variety of components,” explains Jonathan Bouchard, Director Sales and Business Development at Polyrix. “The use of PolyScan offers users various advantages, because it is fast, simple and safe. The measuring system shows its strengths especially in dimensional inspection, in-process quality assurance, and the inspection of components, tools, and models.”

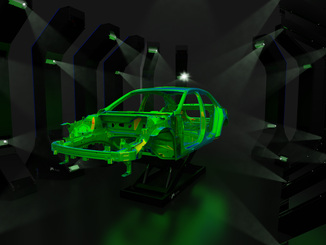

The X-Series range of PolyScan Surround 3D scanners includes a variety of size and configuration options. This ensures complete component detection – from the smallest turbine blade to complete vehicles – with just one scan. Common to all models is the modular column design, vibration isolation, and 2+cameras and 2+projectors. The measurement systems are used in particular in the automotive, aerospace, medical technology, consumer goods, defense, power generation and industrial goods sectors.

The entry into the X series systems is made with PolyScan XS: Among its essential features is the structure made of granite, which – supported by the integrated vibration damping – ensures optimal dynamics in the measurement technology.

PolyScan XM, on the other hand, features the carbon fiber structure for perfect thermal stability in a wide range of environments in a medium-sized package.

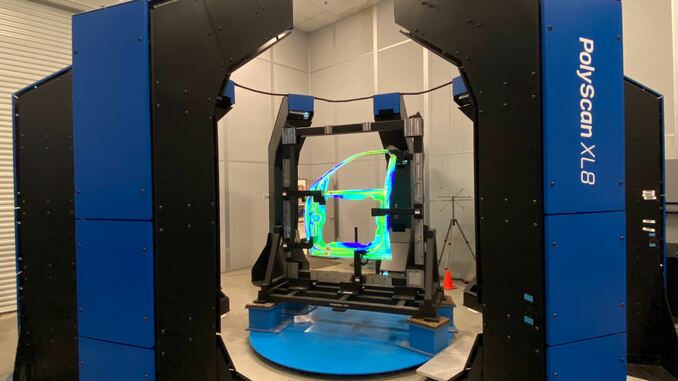

PolyScan XL is available in 6-, 8- and 10-column configurations and enables scanning of everything from car body parts to large, complex aerospace castings.

© Polyrix

PolyScan XH, on the other hand, was designed for the measurement of complete vehicles and can be enlarged as required.

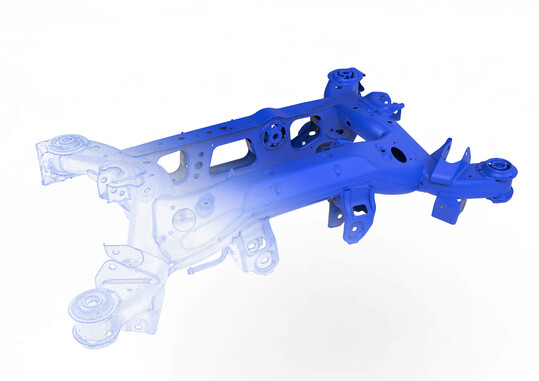

A concise feature of all PolyScan models is “Liveinspection”: Deviations are projected directly onto the respective measuring object by the surround arrangement of the high-resolution projectors. With this technology, the user can apply the color-coded and component-related tolerance spectrum to an individual adjustment and thus obtain dynamic and intuitive feedback at the touch of a button. But PolyScan also offers significant advantages in automated applications: This is because no path planning is required, nor are there any risks with regard to collisions or safety requirements for the robots. In addition, the time-consuming and complicated alignment of individual measurements using reference marks or best-fit in the software is no longer necessary.

In addition, the PolyScan-X series opens up significant advantages on the cost side through a timely return on investment: Millions of measurement points are captured 3 to 4 times faster compared to handheld or robotic scanners – and without user interaction. The creation of complex software programs and their maintenance are also eliminated. In addition, there are only minor requirements for the fixture technology. In addition, no intervention is required on the part before and after the scan – this includes, for example, the application of reference marks or their removal. Last but not least, there are also only low maintenance costs due to the stationary (motionless) arrangement of the S ensorik. “Beyond the costs, PolyScan also offers time benefits, for example through reduced preparation times. Thanks to simple operation, users also require only minimal technical know-how,” summarizes Jonathan Bouchard. “Ultimately, however, what sets PolyScan apart is its attractive overall package, including better analysis options and more visual reporting. After all, POLYRIX stands for smart measurement solutions that enable manufacturing companies to perform and automate inspection processes in an effective and safe way.”

About Polyrix

Founded in 2005, Polyrix Inc. has its headquarters in Saint-Augustin-de-Desmaures (Quebec), Canada. The company offers measurement solutions for industrial production that automate testing processes simply, efficiently and in a safe manner. The PolyScan Surround 3D scanners are primarily used in applications such as dimensional inspection, in-process quality assurance and the inspection of components, tools and models. In this course, the 3D measuring systems convince especially by their fast return on investment, the rapid data acquisition as well as low maintenance costs. Polyrix’s reference customers include renowned companies such as Bell, Boeing, Bosch Rexroth, Collins Aerospace, Ford, Pratt & Whitney, Schneider Electric and Stellantis.

Web:

www.polyrix.com