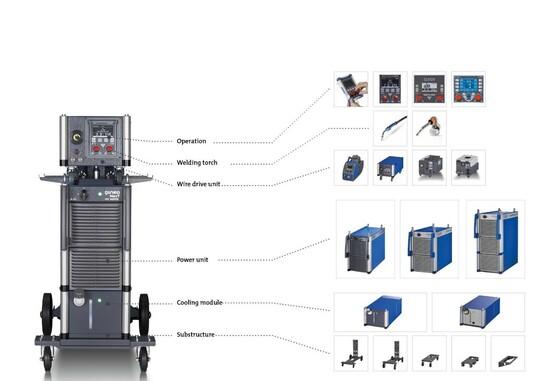

Whether manual or automated welding, thin- or thick-walled materials, use in a production hall or on a construction site – the configuration options of the Quineo welding power sources from Cloos are as diverse as the areas of application for welding. The consistently modular platform concept enables individual solutions that can be tailored to user-specific production conditions and objectives.

© Cloos

“From the power level to the operating module to the special equipment, each Quineo is a custom-made product tailored to the customer’s needs,” explains Björn Fey, who heads Product Management Welding Products at Cloos. “Since we manufacture our welding power sources exclusively in Germany and Europe, we can guarantee maximum quality standards for robust and durable equipment.”

Cloos currently offers three welding power source types: The MIG/MAG welding power source Quineo StarT offers an easy entry into the world of modern welding technology. The Quineo NexT multiprocess welding power source impresses with excellent arc characteristics for high welding quality. The new Quineo QuesT complements the portfolio as a new benchmark for high-end TIG applications.

The modular design of Quineo welding power sources enables versatile applications ranging from basic welding units for manual welding to high-tech welding units for automated robotic welding. The three welding power sources are each available in Eco, Master and Premium versions.

© Cloos

The Premium variant is suitable for automated and manual high-end applications, the Master variant is mainly used for manual applications, and the Eco variant was developed especially for manual applications and offers a limited range of functions and welding processes. The modular construction system runs through the entire Quineo product portfolio with all main components: Operating modules, welding torches, wire drives, water coolers and carriage – users can select the individual components individually, tailored to their specific requirements, and combine them within the product lines.

“In addition to the application-specific configuration, our customers benefit from a more controllable spare parts inventory due to many common parts in our different welding power sources,” Fey explains. “This allows us to ensure an ideal parts supply and minimize downtime in production.”

In addition, Quineo welding power sources can be equipped with common industrial interfaces such as OPC-UA and other optional functions. With Weld-Process-Monitoring (WPM), users can optimally control the quality of their welding production. In addition, the C-Gate IoT digitalization platform enables comprehensive online monitoring of the welding power sources. All welding power sources of the Quineo NexT, StarT and QuesT series can be networked to collect manufacturing and production data.

Web:

www.Cloos.de