Robust manual welding technology, collaborative robotics, scalable automation solutions and innovative data management: For manufacturing companies, plants and production facilities around the world, Cloos combines the benefits of progress with the quality needed to achieve the best results.

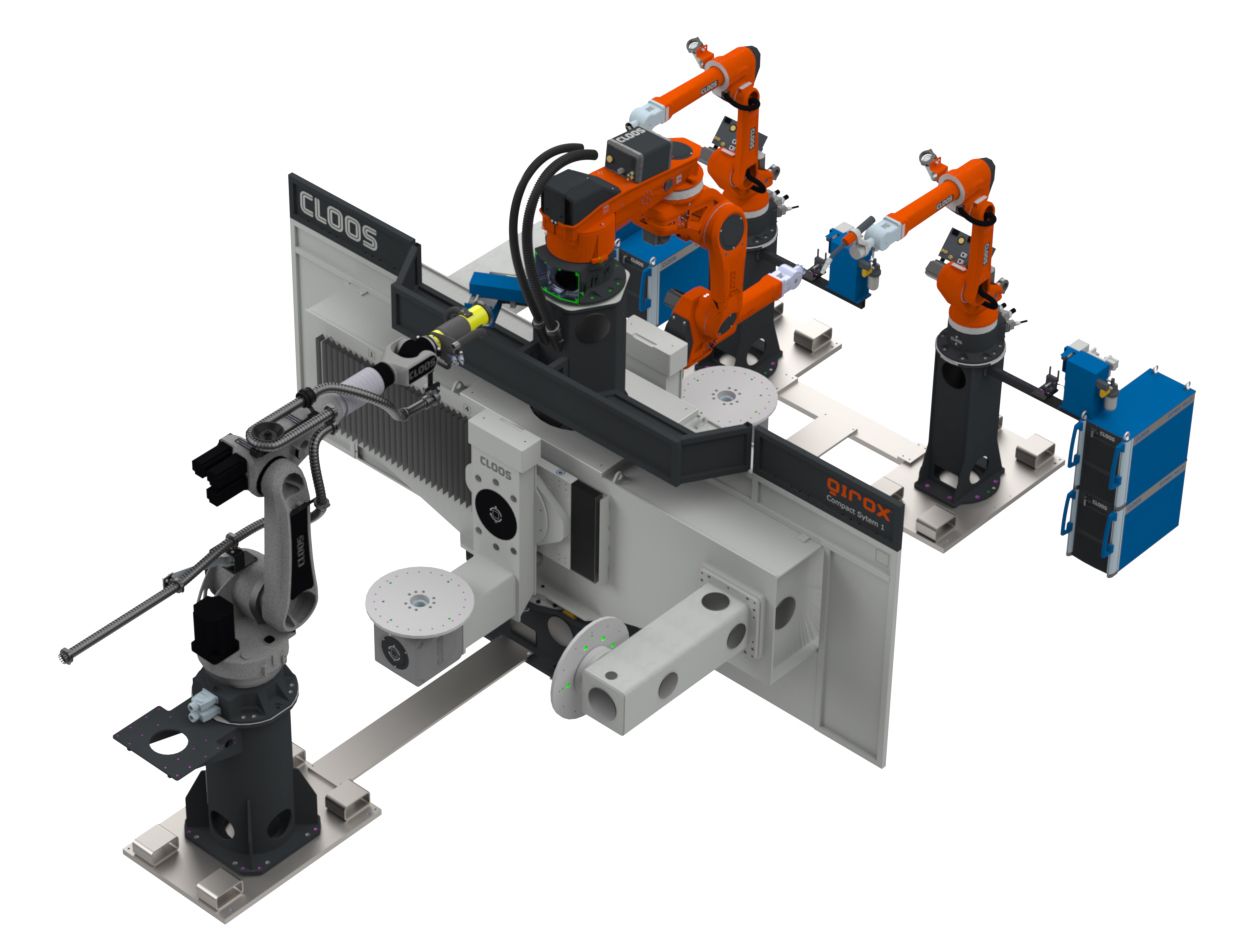

A highlight of the booth in Essen is the automated high-tech production line, in which automated welding technology is integrated with handling and grinding applications in one production line. By combining innovative welding technology with upstream and downstream production processes, users can close automation gaps and significantly increase the efficiency of their welding production.

© Cloos

Closing automation gaps

The Qirox system includes robotics, positioners, safety technology, software, sensors and the interface to process technology. The Cloos product spectrum ranges from simple, compact standard systems to complex, interlinked systems with independent component identification and automatic loading and unloading processes. The modular design provides users with scalable solutions that are optimally adapted to different applications and individual production requirements – whether small, delicate workpieces or large, complex components.

In addition, Cloos will present the Qineo ArcBoT, which offers an easy entry into automated welding technology, relieves employees and ensures consistent, reproducible welding quality. The high-tech Qineo welding power source and the high-precision Cobot complement each other perfectly, according to Cloos.

Manual welding from entry to premium

During demonstrations in the manual welding area, trade visitors will be able to experience live the constantly growing product range of Qineo welding power sources from entry to premium. The Qineo StarT provides an easy start into the world of modern MSG welding technology. The high-tech Qineo NexT MSG welding power source impresses with excellent arc properties for high welding quality. The modular design enables a wide range of applications, from the basic welding unit for manual welding to the multi-process welding unit for automated robot welding. In addition, the Qineo QuesT complements the portfolio for high-end TIG applications. This welding power source was specially developed for TIG welding processes and is particularly suitable for the most demanding welded joints and the highest quality requirements. The Qineo welding power sources are characterized in particular by digital connectivity, maximum energy efficiency and the possibility of integrating new welding processes.

The right welding process for every requirement

In addition, Cloos will present new and proven welding processes for highest productivity and quality. Whether thick or thin, aluminum or steel, manual or automated – the wide range offers the right welding process for every individual product requirement.

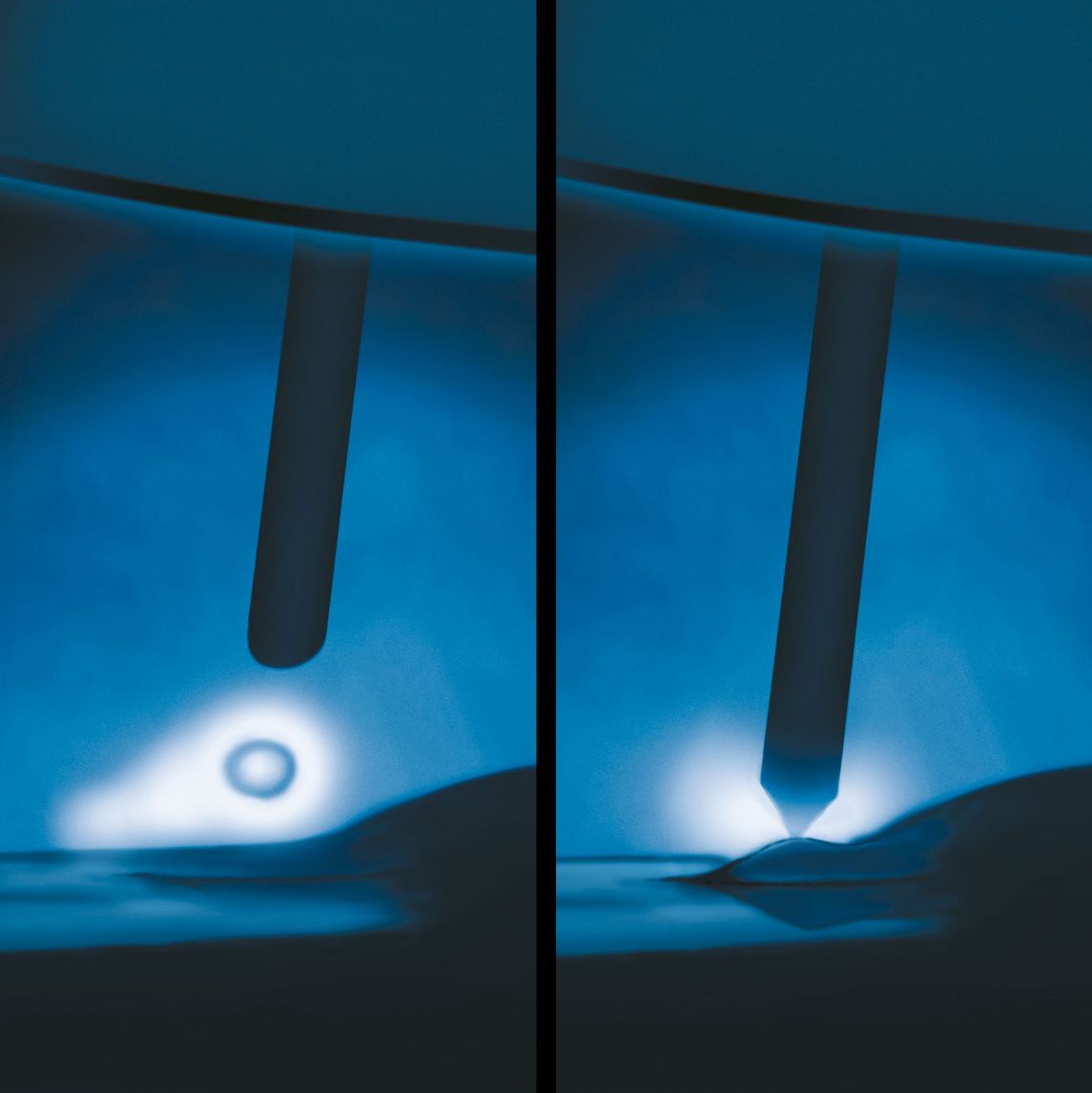

With the new Mix Weld welding process, users solve demanding welding tasks even with heat-sensitive materials. Ridge seams and transverse positions can also be welded linearly with this process, which significantly saves time in the process sequence.

MoTion Weld is particularly suitable for applications in the thin sheet sector and for applications down to the lowest power ranges. The welding process shows its strengths wherever special requirements are placed on the seam surface and appearance.

With Tandem Weld, the high deposition rate can be converted into both welding speed and volume fill, which offers advantages for thin and thick sheet thicknesses. Users benefit from shortened welding times and reduced rework, thanks to minimized component distortion, low line energy and good gap bridgeability.

ensures consistent, reproducible welding quality.

© Cloos

Digitization solutions for the manufacturing of the future

Cloos’ software solutions further enhance the performance of welding equipment and robotic systems. With the C-Gate IoT platform, users can access real-time information from their welding production. Thanks to central data acquisition and processing, users can monitor their production processes down to the smallest detail and control them with foresight. C-Gate consists of several modules that users can activate depending on their individual digitization strategy – continuous from the manual welding power source to the fully automated production line.

In addition, Cloos’ RoboPlan software enables offline programming of automated robot welding systems. With RoboPlan, welding and traverse paths as well as sensor routines are created on 3D models and transferred directly to the robot’s controller. This increases equipment utilization, optimizes the manufacturing process and makes welding production more flexible.

At Schweissen & Schneiden, Cloos will also be presenting for the first time the new digitalization system.

platform Qnect. In the future, all digital solutions from Cloos will be integrated here so that users have all information available at a glance.

Hall 3, Booth 3C63

Web:

www.cloos.de