Belgian company Engicon nv (Geldof) is known for its technically complex solutions that often require a wide range of expertise. It specializes, among other things, in the manufacture of storage tanks, pressure vessels or equipment for the storage and handling of bulk materials. When an outdated plasma cutting system in the cutting area had to be replaced, the company was looking for a modern solution including a chamfering unit.

© MicroStep Europe

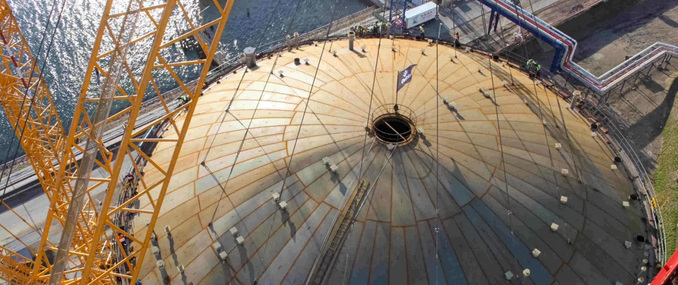

Engicon nv (Geldof), based in Harelbeke, Belgium, is a leading European supplier of integrated steel solutions for the storage, handling and processing of liquid, solid and gaseous bulk materials. The strategic location on the banks of the river Leie with direct access to the major ports of Ghent and Antwerp gives Engicon easy access to the global market. Engicon’s own wharfage allows the loading of goods up to 300 tons, 150 m in length and 15.5 m in diameter onto barges. Large constructions can be easily transported by ship or truck.

Plasma rotator required to reduce costly rework

In the cutting area, the company relied for many years on a 2D plasma cutting system, which was due to be replaced in 2017 after 31 years of service. Engicon also saw the exchange as an opportunity to expand its manufacturing capabilities and take precision and quality to a new level. Above all, the company wanted to incorporate bevel cutting into its production: after all, the automated application of weld preparations requires no further finishing. The ready-to-weld edges thus created significantly reduce processing time and manpower requirements.

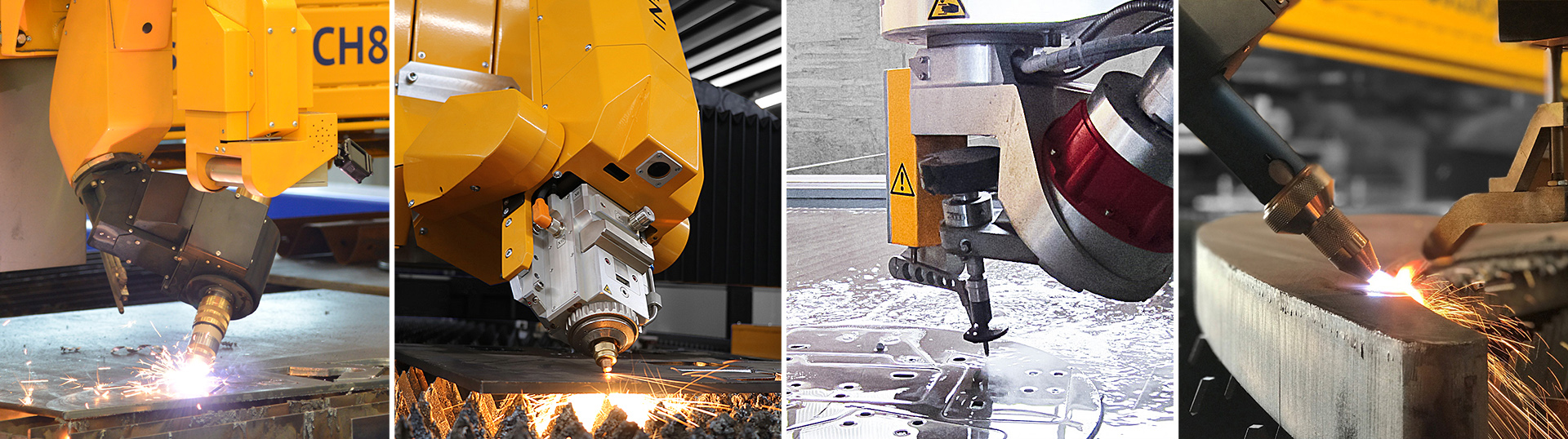

After careful consideration, Engicon decided to purchase a MicroStep machine from the MG series. The company was looking for a stable and permanently precise solution that would ensure consistent quality even in multi-shift operation. Engicon usually produces in two shifts and cuts about 10,000 to 15,000 tons of steel per year. The new plant went into operation in the spring of 2018. With a work area of 14 x 4 meters and an integrated technology combination of a plasma rotator for 3D sheet metal processing and an oxyfuel torch for larger material thicknesses, Engicon relies on a versatile CNC cutting center capable of producing a wide range of parts from sheets of different sizes and thicknesses.

© MicroStep Europe

Parts marking ensures traceability of sensitive components

In addition, a needle marker has been integrated, which applies the batch number of the original sheet to the individual cutting parts. This ensures traceability of production – an important option especially in the manufacture of sophisticated tanks for sensitive goods. This way, in the event of a potential part failure, all parts of the same sheet metal batch can be identified and potential problems can be corrected at an early stage.

Another criterion in the configuration of the new 3D cutting system was the integration of a shuttle table. After careful analysis and intensive exchange, Engicon and MicroStep decided to use a system from German cutting table specialist Tecloga due to the planned size of the table. The 14 x 4 meter shuttle table was designed in such a way that after cutting the grid with the finished cut parts moves to a separate room and only there the parts are unloaded. This solution makes unloading as well as subsequent loading with the new material much safer.

Several measures to protect employees

To protect its employees, Engicon has implemented high safety, health and environmental standards. For this reason, a separate hall was even built for the new machine, specifically for the requirements of plasma and oxyfuel cutting. In addition to the separated premises for the cutting process and the loading and unloading process, further measures were implemented. “Special light barrier protection and an ergonomic operating system have been installed around the machine. There is even a separate control room for the operator,” explains Dieter Vandeputte, Maintenance & Facility Manager at Engicon.

Web:

www.microstep.com