New and enhanced products are leading to very high cleanliness specifications in many industries. Similarly, changes in manufacturing, joining and coating technologies, as well as more stringent regulatory requirements, result in stricter requirements for particulate and filmic component cleanliness. In order to meet these values in series production reliably and efficiently, not only do you need cleaning and drying processes designed to meet requirements and suitable plant technology, but also the software implementation and the cleaning environment must be adapted accordingly.

© Ecoclean

Whether production equipment for the semiconductor industry, biotechnology, laser and sensor technology, devices for measurement and analysis technology, components for accumulators and fuel cells, optical systems or machine tools, the demands on the performance and reliability of the products are enormously high. This results not only in high demands on the manufacturing precision of the components, but also on their cleanliness.

For medical devices such as implants, instruments, cannulas and endoscopes, particulate and filmic contamination from manufacturing processes is a major criterion due to stricter regulatory requirements. In addition, there is the trend towards miniaturization and function integration with ever smaller and more complex components. These developments mean that particulate cleanliness specifications in the micro- and nanometer range, as well as very stringent specifications regarding residual film contamination, are being demanded in more and more industrial sectors.

Depending on the component or application, outgassing rates for organic substances and residual moisture must also be observed, as well as limit values down to the atomic percent range for surface analyses for residues of prohibited substances. In the production of these miniaturized parts, there is also a trend towards ever larger, integrated manufacturing modules. This also poses new challenges for the cleaning processes and the plant technology required for them. This results in very demanding tasks for component cleaning that span the entire production chain.

As a complete provider of future-oriented solutions, the companies of the SBS Ecoclean Group cover the entire spectrum of precision and ultra-fine cleaning. This makes it possible to adapt cleaning processes and their software control as well as equipment and the ambient conditions to the respective requirements and applications.

© Philips Medical Systems

The right plant concept

When selecting the appropriate cleaning system for a specific task, the first consideration is whether pre-cleaning, intermediate cleaning or final cleaning is to be carried out. Depending on the application and the cleanliness requirements to be achieved, the solution can be a chamber or in-line immersion cleaning system, flexible ultrasonic in-line immersion system based on standardized modules, or an individually designed ultrasonic fine cleaning system.

Cleaning chemistry and the most suitable process technologies, such as spray, high-pressure, immersion, ultrasonic or megasonic and plasma cleaning, injection flood washing, pulsed pressure cleaning (PPC) and, if required, passivation/preservation, are also matched to the application and the contaminants to be removed.

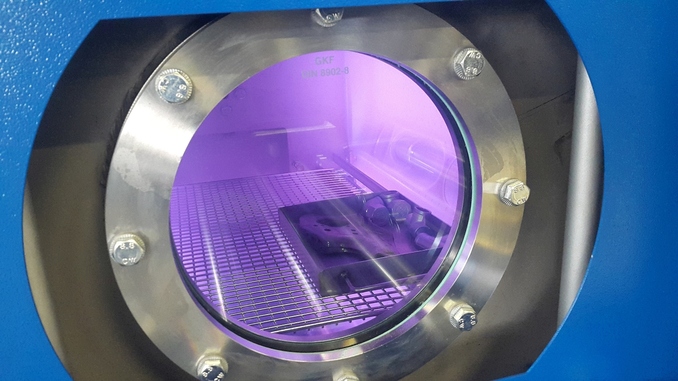

Cleaning processes and equipment for highest purity

The design of individually configured ultrasonic multi-chamber systems and processes for ultra-fine cleaning are the core competence of the Swiss UCM AG. Key factors are the material and geometry of the workpieces to be cleaned, the type and amount of contaminants, the particulate and film cleanliness specifications to be achieved, and, if applicable, permissible outgassing rates and maximum permissible residues of prohibited substances in the atomic percent range.

In addition, attention is paid to the selection of suitable cleaning chemicals and the media supply, for example the use of osmosis or fully demineralized water. The materials and manufacturing processes used for the construction of the cleaning plant and automatic transport systems are selected with a view to avoiding the formation of dirt as well as re- and cross-contamination. Clean room compatible equipment as well as the connection to a clean room can also be realized.

Photo: Jürgen Scheere/ZEISS

Standard in systems for precision and ultra-fine cleaning are multi-frequency ultrasonic systems that allow flexible adjustment of the frequency and intensity of the ultrasound to the requirements of different workpieces. For complex components, capillary structures or porous surfaces, for example of components produced in sintered metal and additive manufacturing technologies, the PPC process can also be considered.

Equipment features such as a multi-sided overflow in all cleaning and rinsing baths as well as immersion spray rinses specially developed for ultra-fine cleaning help to meet very high cleanliness specifications in a process-safe manner. The determination of which cleaning and rinsing baths are used with which workpieces, as well as the component-specific process parameters such as temperatures, power and frequency of the ultrasound, PPC intensity, dwell time in the various cleaning and rinsing baths, is carried out during process development.

Drying is usually implemented as infrared and/or vacuum drying, depending on the component complexity and heat absorption capacity. The resulting part-specific cleaning programs are stored in the system control A decisive role is also played by the software implementation of the cleaning sequence. Among other things, it ensures that the specified dwell times in the cleaning and rinsing sinks are precisely adhered to and that prioritized processes can be carried out, for example for very sensitive components. Which system and process solution is best from the point of view of cleanliness and economy can be determined by cleaning trials in Ecoclean’s and UCM’s precision technology centers using original components.

Ecoclean

The SBS Ecoclean Group develops, produces and sells future-oriented equipment, systems and services for industrial component cleaning and surface treatment. These solutions, which are among the world leaders, help companies around the globe to produce efficiently and sustainably in high quality. The customers come from the automotive and supplier industry as well as the broadly diversified industrial market – from medical, micro and precision engineering to mechanical engineering and the optical industry to energy technology and the aviation industry. Ecoclean’s success is based on innovation, cutting-edge technology, sustainability, customer proximity, diversity and respect. The group of companies has twelve locations worldwide in nine countries and employs more than 900 people.