© Schuler

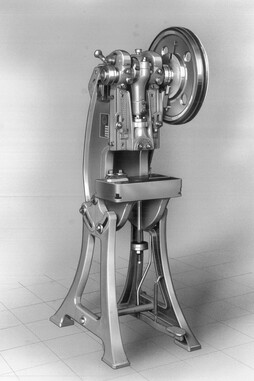

In 1932 Domenico Farina founded his company “Costruzioni Meccaniche Farina”, a workshop for the production of stamping tools. However, in order to test them, a press was needed – and so the first machine was born. Since the 1970s, Farina Presse has designed and built exclusively forging presses. In 2018, the company became part of the Schuler Group.

“We can cover the entire production process within the company, from planning to installation and service,” emphasizes Managing Director Marco Gritti. “Equipment to complete – and automate – the forging process complements the product line.” In addition, the company and its 40-plus employees also carry out modernizations on existing presses.

© Schuler

First automation attempts in the 1940s

The story of Farina is also a story of innovation. As early as the 1940s, the company experimented with automating the cutting of metal strips. In 1956, Domenico Farina presented a safety system with a multi-beam light barrier at the Milan Fair. The first press for forging hot steel, the T 630, was developed and put into operation by a local company in 1968. Given the excellent return on investment, other forges soon began to demand the new equipment.

In the 1980s, the product range was expanded to include several machines with press forces from 4,000 to 25,000 kilonewtons. The first programmable logic controller arrived in 1984. In 1999, the GAS 2000 transfer press was developed and manufactured, followed the next year by the GAS 1000 and 3500. In 2006, the GLF press series was introduced, featuring extremely fast and precise forging as well as a larger working range at maximum output.

World’s biggest plant for thyssenkrupp

© Schuler

In 2018, Schuler acquired Farina Presse, strengthening its market position in the mid-range performance segment. Farina Presse gained access to Schuler’s worldwide distribution network for its products and continues to operate under its own brand name. Together the two companies succeeded in building the world’s biggest forging line in 2021: a 160,000-KN press for thyssenkrupp Gerlach.

One of Farina’s latest innovations is the Kers kinetic energy recovery system, which not only reduces energy requirements by up to 40 percent, but also increases output and reduces maintenance costs. In a conventional press, most of the energy goes into accelerating and stopping the slide at the top reversal point. In a Kers press, this energy is recovered by a torque motor that is directly connected to the eccentric shaft. In addition, brake and clutch wear, vibration and associated noise are eliminated, resulting in a more comfortable environment for operators.

Web:

www.schulergroup.com