Whether cranes, construction machinery, railroads, mining or industrial plants – Wit-Metal manufactures the right parts and assemblies for them. Customers demand a lot from the Polish supplier because the end products are subject to high standards. They can meet these requirements with straightening and deburring machines from Arku.

© Arku

When Jan Matusiak founded his metalworking business in Sieradz, not far from Lodz, almost 40 years ago, he had no idea what a success story he was starting. But with him and his son Witold, the current owner of Wit-Metal, the company continued to develop. New customers and new machines were added. Today, Wit-Metal produces parts and assemblies that are used in special vehicles such as cranes and construction machinery. The portfolio also includes wagon and train parts as well as industrial constructions. The customer spectrum is also broad and ranges from the local community to large corporations.

Specialist for processing thick sheet metal

One of Wit-Metal’s main focuses is on thick materials. “70 percent of our sheet metal is between 8 and 35 millimetres thick, the rest is thinner or thicker,” says Witold Matusiak. Most of the end products are used outdoors, which places high demands on the surface. Other parts and assemblies made from Sieradz can be found in production machines, indoor cranes or mining machines that are used in enclosed spaces.

Wit-Metal was confronted with the increasing demands of its customers, as were numerous other suppliers. The aim was to achieve greater flatness of the sheet metal and sheet metal parts. In its search for a solution to these requirements, the company came across Arku Maschinenbau in Baden-Baden. After successful straightening trials in the machine manufacturer’s straightening and deburring center, the FlatMaster 88 straightening machine moved into Wit-Metal’s production facility in 2018. The machine was up and running, confidence grew, and so after additional deburring trials, the EdgeBreaker 4000 deburring machine and another FlatMaster 120 straightening machine followed to Sieradz.

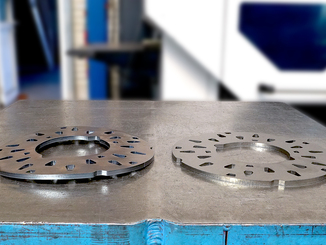

The variety of sheet metal parts that are processed with Arku machines is huge. “In every project, there are parts that need to be straightened. They then form the assemblies of vehicle frames, cranes, dump trucks, excavators, mining vehicles or are installed for the timber industry and railroads. In addition to vehicles, there are also parts for industrial plants,” explains Matusiak.

© Arku

Customers demand flat and clean parts

Each machine is operated by one employee. Depending on their size, the workpieces are placed on and removed from the machines manually or using cranes or overhead cranes and traverses. “We attach particular importance to order at the workstations,” emphasizes the owner.

As the straightening and deburring process itself runs automatically, the operator can concentrate on checking the workpieces and placing them in the correct stack. Wit-Metal’s customers also expect the parts to be free of dirt, scale or slag and for the edges to have a radius rounding. “The deburring process ensures that we meet all these requirements,” confirms Matusiak.

With the Arku systems, Wit-Metal is also supporting the trend towards greater sustainability. “Our way of increasing sustainability is to extend the life cycle of products,” promises the owner. For steel products that are painted, the quality of the surface and the rounding of the edges are particularly important. If the paint coating adheres better as a result, the corrosion process starts later and more slowly. This extends the service life of the products accordingly.

© Arku

Straightening systems save tedious work with bending machines

Before the purchase of Arku part straightening machines, Wit-Metal did not offer customers any straightening work. If parts had to be straightened, the employees had to do this on bending machines. “That’s why the purchase of the straightening machines and the deburring machine was a technological and qualitative leap for us,” explains Matusiak. Today, almost 100 percent of the parts are straightened – either because this makes internal work such as bending more successful or because the customers themselves place demands on flatness.

From a sheet thickness of six millimeters, all parts are also deburred. For thinner sheets, this is not absolutely necessary for Wit-Metal. “We mainly deburr parts that are wet-painted or powder-coated. They require an edge rounding of up to 0.3 millimetres,” explains the owner of Wit-Metal.

Wit-Metal now uses all three Arku machines continuously. The EdgeBreaker works three shifts around the clock, while the two FlatMaster machines each work one and a half shifts. This enables the supplier to deburr almost 160,000 sheet metal parts and straighten over 130,000 workpieces. “These figures have risen steadily over the past three years,” says Matusiak happily.

© Arku

Great time savings when deburring heavy sheet metal parts

The EdgeBreaker 4000 deburring machine is particularly useful because it saves a lot of time: there is no need to turn the workpieces because it deburrs on both sides. This is particularly evident with large and heavy parts that can only be handled with the help of cranes. As only one pass is required for deburring, the total processing time is reduced to a fraction.

Compared to the previously used hand-held tools, the deburring machine is significantly faster and more efficient. In addition to saving time, Wit-Metal was able to expand its range of services. The supplier was also able to better meet edge requirements and increase repeatability.

Matusiak is even clearer about the straightening machines: “In a word: it was a milestone.” The investment was a technological leap forward – both in terms of internal processing and for customers: “We offer better quality and gain new customers and new orders as a result.”

He originally purchased the FlatMaster 88 for orders from trailer and semi-trailer manufacturers. “Thanks to the straightening machine, we won orders in the construction machinery sector, and then the railroad sector followed. Today, these two are our most important customer segments,” recalls Matusiak. It was only with the Arku machines that Wit-Metal was able to start working together in the production of railroad wagons. Previously, the requirements for the existing machines were too high; the parts for the railroad had to have a higher degree of flatness. In addition, at a time when steel was scarce and the material was of poorer quality, the supplier was able to purchase without worrying and straighten crooked sheets itself. As a result, Wit-Metal did not suffer any shortages.

© Arku

Simple machine operation helps combat the shortage of skilled workers

Those who also benefit from the Arku machines are the employees at Wit-Metal. All they have to do is place the workpiece on the feeder, start the machine and remove the finished part. This means much better ergonomics. The machine operators also benefit above all from the simple operation of the machines: “It is intuitive, safe and fast. Our employees only needed a brief introduction to the operation,” reports Matusiak.

Wit-Metal is also beating the shortage of skilled workers with its deburring system and part leveling machines. “In general, the situation on the labor market is also difficult for us in Poland,” explains Matusiak. He continues: “The fact that Arku machines are easy to operate means that less qualified employees can also work on them. In this way, we can use skilled workers with more experience for other tasks.”

And the development at Wit-Metal goes on and on. The big goal in Sieradz is: Industry 4.0. “We are striving to fully integrate processes into our ERP system. Every workstation in the company is already equipped with a unit for logging processes. This gives us full control over production and the ability to plan work precisely,” explains Matusiak. And automation is also progressing. “We will be installing robot bending machines this year. I can hardly wait either,” says the owner of Wit-Metal happily. With perfectly aligned and deburred parts, the right conditions are already in place.

Author:

Stéphane Itasse

Background

Founded in 1928, the family-owned company Arku Maschinenbau GmbH is the world market leader in straightening technology with almost 60 years of experience. Arku offers the widest range of high performance and precision levelers as well as deburring and rounding machines. The range is rounded off with part handling solutions for straightening and deburring machines.

With its headquarters in Baden-Baden, Germany, and ISO-certified subsidiaries in Kunshan (China) and Cincinnati (USA), the company covers markets in more than 30 countries. Arku offers contract work in the straightening and deburring centres at the three locations with highly modern and powerful machines.

The product range includes precision part straightening and deburring machines, automated part handling with robots, coil straightening machines, cut-to-length lines, press feed lines and strip preparation lines for profilers. The Arku machines are used in industrial sheet metal processing. From the automotive industry, mechanical engineering and the furniture industry to shipbuilding, steel construction and the railway industry to laser job shops and flame cutting companies: Arku supplies deburring and straightening machines all over the world.

Web:

www.arku.com