Hatec GmbH in Pönning, not far from Straubing on the Danube, demonstrates how a supplier can grow: what was once a repair business for agricultural machinery has now become a medium-sized company with 280 employees at two locations. Two systems from Arku Maschinenbau play an important role in the expansion.

© Arku Maschinenbau GmbH

The focus on quality at Hatec cannot be overlooked. The medium-sized company from Lower Bavaria has not only passed a considerable number of certifications. The machinery is also right up to date. The company is also characterized by its range of services: Hatec now offers more than just metalworking and has expanded its portfolio from metalworking to the assembly of complete subassemblies. In sheet metal and tube processing, the medium-sized company offers laser cutting of blanks, milling if required and, last but not least, joining into assemblies. A machine park that the company always keeps up to date is indispensable. For example, Hatec recently switched to fiber lasers. Customers from the commercial vehicle, agricultural machinery, logistics and medical technology sectors appreciate this.

Flatness and edge rounding are becoming more important

“Our customers are placing more and more value on flatness and rounded edges when cutting to size,” reports Markus Heinrich, Technical Operations Manager at Hatec. This is due to the fact that the coatings adhere better to burr-free, rounded edges. The switch from CO2 to fiber lasers is very important for production planning, as more parts need to be deburred. The flatness and stress reduction of the individual parts are in turn important in order to avoid welding distortion in welded assemblies as far as possible. “We and our end customers want to work more effectively,” says Heinrich. This applies to individual parts, welded assemblies and right up to assembly, which becomes easier if the tolerances for flatness are tighter. Hatec first made contact with Arku Maschinenbau at a trade fair. “We were looking for a new straightening machine,” recalls Heinrich. Although Hatec already had a roller straightener in use, it was too inaccurate and its output was too low. Some of the sheets and sheet metal parts required several passes on the straightening machine until the required flatness was achieved. The maximum dimensions were also restricted. The employees had to straighten larger parts on a hydraulic press. This meant a much greater investment of time.

© Arku Mechanical Engineering Ltd.

Convincing test runs at Arku

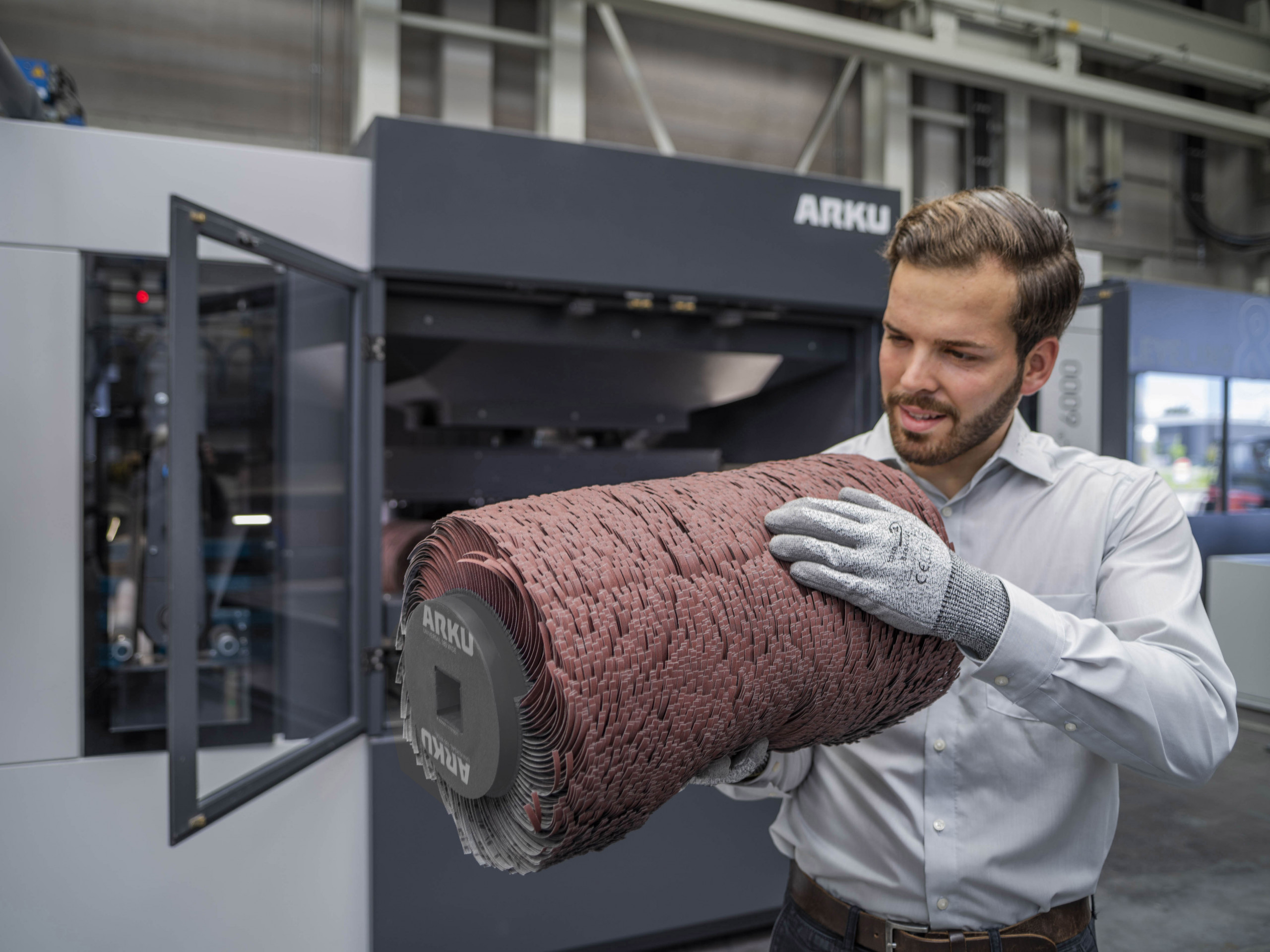

Hatec and Arku agreed on the requirements for the new straightening machine while still at the trade fair. Heinrich and a colleague then drove to Baden-Baden to do some test runs. In their luggage, they had exactly the parts that caused them the most headaches when straightening. “When we saw how they were perfectly aligned after one pass, we were really impressed,” recalls the Technical Operations Manager. The robustness of the straightening machines and the comparatively low maintenance requirements also spoke in favor of Arku. The decision was therefore quickly made in favor of a FlatMaster 88. “This precision straightening machine is particularly suitable for straightening laser, punched and flame-cut parts,” explains Christian Nau, sales representative at Arku. For several years, two operators worked on the Arku straightening machine: one to load the system, one to unload and destack. At the same time, two other operators were working on an old wet deburring machine. But the shortage of skilled workers is hitting everywhere, including Hatec. “Finding suitable staff is a major challenge, and it will probably remain so,” reports Heinrich. He and his team therefore looked for ways to make the processes more efficient – and came across Arku again. The idea: If all sheet metal parts have to be deburred before straightening anyway, the FlatMaster 88 can also be linked to an EdgeBreaker 4000 deburring machine. Here too, the experts from Hatec took the opportunity to test the parts at Arku. And again they were convinced of an Arku machine. Without much hesitation, the Lower Bavarians procured an EdgeBreaker 4000 because, unlike the old wet deburring machine, it works on both sides. “This saves the operator at least a second pass and the need to turn the parts in between,” explains Nau, adding: “The machine’s powerful deburring roller reliably grinds off even the most stubborn burrs from the fiber laser. The second unit with the deburring brushes rounds the edges cleanly.” Heinrich sees another advantage compared to the old wet deburring machine: “A dry deburring machine is significantly easier to maintain.”

© Arku Maschinenbau GmbH

Clever interlinking reduces personnel requirements

At Hatec, the EdgeBreaker 4000 and the FlatMaster 88 are directly interlinked by conveyor belts. Two operators are now sufficient: the first places the parts for the straightening machine, the second removes them from the outlet of the deburring machine and stacks them. In the meantime, all parts that are large enough run through the interlinking of EdgeBreaker 4000 and FlatMaster 88. A minimum size of 200 millimeters is required for the double-sided deburring machine, “but that applies to 90 percent of our parts,” says Heinrich. The material used is mainly structural steel, but stainless steel and aluminum are also used. “That’s the case with every machine: You have to clean it thoroughly before changing the material,” explains the Technical Operations Manager. At Hatec, production is then organized in such a way that as many aluminium or stainless steel parts as possible are deburred at once during a material change. Employees can then save themselves a cleaning operation or two for the EdgeBreaker 4000. The advantages of the Arku machines have now clearly crystallized at Hatec. “We now have better quality. This results in lower costs because we have less work to do with reworking,” says Heinrich, expressing his complete satisfaction. Author: Stéphane Itasse, freelance journalist in Eibelstadt

Brief profile

Founded in 1928, the family-owned company Arku Maschinenbau GmbH is the world market leader in straightening technology with almost 60 years of experience. Arku offers the widest range of high performance and precision levelers as well as deburring and rounding machines. The range is rounded off with part handling solutions for straightening and deburring machines.

With its headquarters in Baden-Baden, Germany, and ISO-certified subsidiaries in Kunshan (China) and Cincinnati (USA), the company covers markets in more than 30 countries. Arku offers contract work in the straightening and deburring centres at the three locations with highly modern and powerful machines.

The product range includes precision part straightening and deburring machines, automated part handling with robots, coil straightening machines, cut-to-length lines, press feed lines and strip preparation lines for profilers. The Arku machines are used in industrial sheet metal processing. From the automotive industry, mechanical engineering and the furniture industry to shipbuilding, steel construction and the railway industry to laser job shops and flame cutting companies: Arku supplies deburring and straightening machines all over the world.

Web: www.arku.com