Kemppi launches the X5 FastMig Pulse welding machine, specifically designed for industrial use. The modular welding solution is designed for different applications in different environments; this means that the customer can put together the configuration that best meets his requirements.

© Kemppi

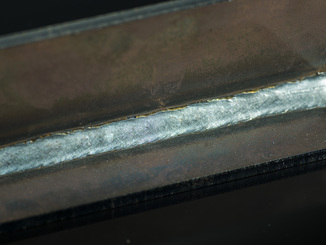

The X5 FastMig Pulse was designed and manufactured in Finland. The multiprocess welding machine for industrial welding was developed in cooperation with professional welders. The X5 FastMig Pulse is a versatile powerhouse for arc welding built with energy-efficient inverter technology. The power sources are available with 400 A and 500 A and now also with pulsed MIG welding function. Eight different wire feed models are available for this purpose, including new APC models with digital connectivity and HD models for demanding conditions.

“The ease of use, the efficiency of the production processes and the good ergonomics guarantee a successful result without compromising on the excellent welding quality. Welding with TIG, MIG or MMA processes with one and the same system has never been so straightforward,” promises Product Manager John Frost.

“In addition, the X5 FastMig Pulse’s integrated data acquisition of welding parameters enables real-time control of weld quality and work phases,” Frost added.

© Kemppi

Digital data acquisition of welding parameters requires an X5 FastMig APC wire feeder. Sales of the X5 FastMig Pulse will begin in October 2022. Sales of the Master M 358, which was already presented in spring 2022, will start at the same time.

According to Kemppi, the Master M is a compact yet powerful MIG/MAG welder that combines top-notch welding performance with excellent ease of use for manual, synergic and pulsed MIG welding.

“The Master M enhances industrial welding performance. The digital arc control, fast set-up and excellent power-to-weight ratio set new standards for welding quality and work efficiency,” explains John Frost.

The Master M-Series includes three top-of-the-line models with manual and automatic parameter setting (353) or Manual, Auto and Auto Pulse methods (355 and 358).

The integrated LED work lights provide safety and comfort during daily work. The practical additional light source, with or without mains connection, increases safety and boosts productivity in poor lighting conditions. For higher welding cycles, the Master M Cooler assists and increases the output of the 350 A welding power source with 40 percent duty cycle. The Safe Lift design ensures that the Master M can be carried by hand or suspended by crane. This provides safe and convenient transport of the power source on the construction site. In addition, four optional crawlers, including the new T35A, support specific operating conditions and transport of the welding machine on the job site.

WeldEye ArcVision captures data about welding parameters

WeldEye ArcVision is an integrated Industry 4.0 solution that captures welding parameters, arc-on time and filler metal consumption. Data is collected from digitally connected welding stations and wirelessly transmitted to the cloud-based WeldEye ArcVision service. WeldEye ArcVision presents the welding data in clear tables and graphs that can be filtered as needed.

“WeldEye ArcVision helps measure welding machine operation and arc-on time, as well as record welding parameters. Welding data presented in tables and graphs are easy to interpret in WeldEye ArcVision. In addition, real-time data makes weld quality control more efficient and speeds up work phases,” explains Vesa Tiilikka, Manager, Digital Services at Kemppi.

Buyers of the X5 FastMig can try the cloud-based WeldEye ArcVision service free for three months. APC models of the X5 FastMig wire feeder connect wirelessly to WeldEye ArcVision without additional equipment.

Web:

www.kemppi.com