Newsletter

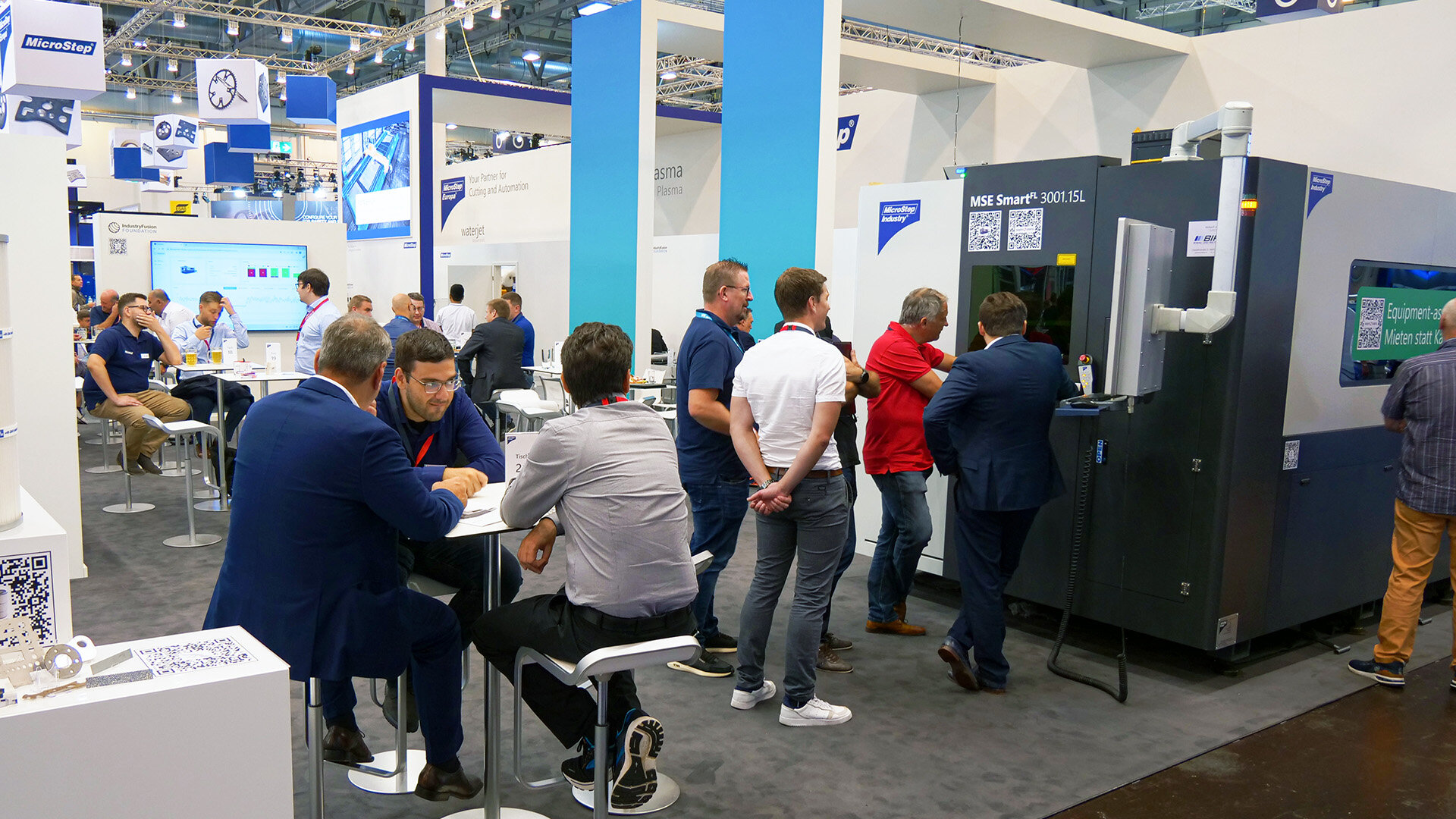

Enormous time savings thanks to integrated quality assurance

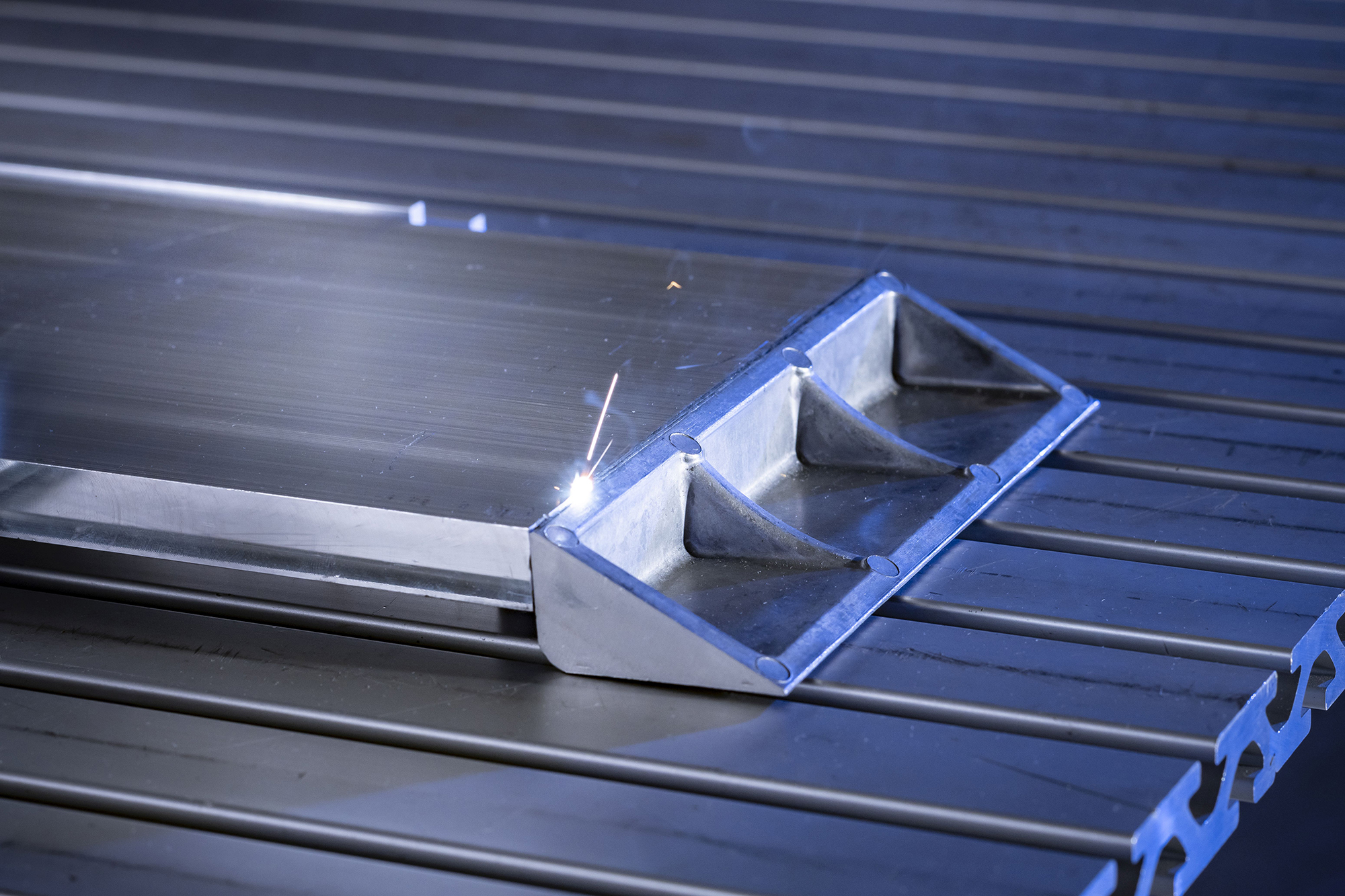

Don’t be confused by the fact that, apart from the holding devices, you are not looking at sheet metal parts but die-cast parts. After all, there are high quality requirements […]