Laser processes with dynamic beam shaping enable stable connections even of critical material pairings. New applications show how additional materials can be dispensed with while at the same time improving quality, energy efficiency and the production process.

René Jungnickel/Fraunhofer IWS

At the “Schweissen & Schneiden 2025” trade fair, the Fraunhofer Institute for Material and Beam Technology IWS presented laser welding solutions that expand both design and economic scope. The focus was on intelligently guided blasting processes that do not require additional materials and can be easily transferred to real production scenarios. This technology is used, for example, in lightweight structures for e-mobility, tank structures for aviation and load-bearing components in heavy steel construction.

Several current development projects rely on laser joining processes. A targeted moving beam actively influences the behavior of the molten metal and makes it possible to dispense with filler materials. “We are demonstrating that even the most challenging welding tasks, such as joining alloys that were previously considered difficult to weld or component cross-sections of considerable size, can be implemented robustly and productively with less energy, material usage and rework,” explains Dr. Axel Jahn, head of the Joining department at the Fraunhofer IWS. “The combination of high-frequency scanner technology, flexible beam power control and our open-system process control opens up new application perspectives and design possibilities that conventional arc technologies do not offer.”

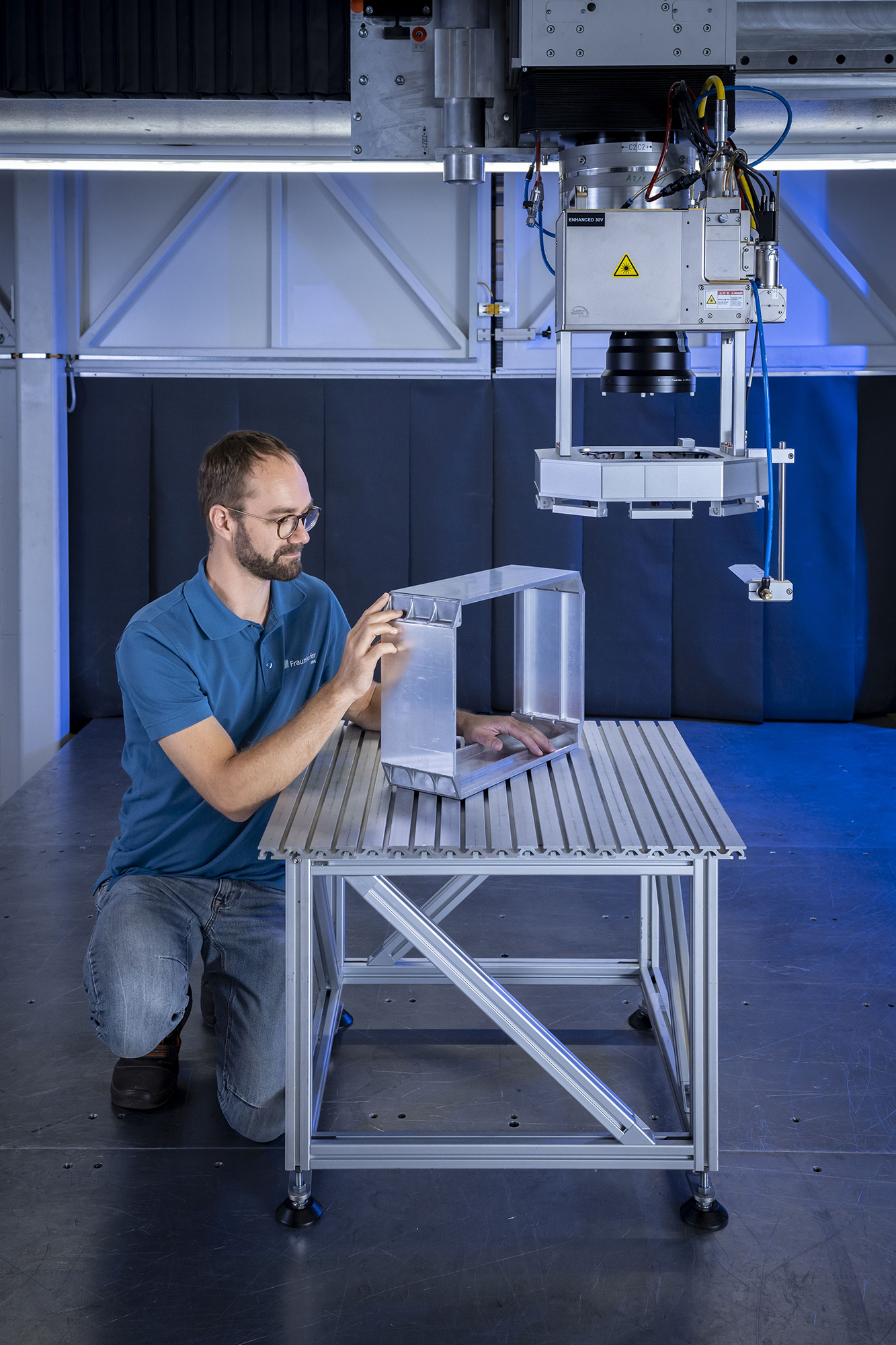

Aluminum battery housing: without additional wire, crack-free and low-porosity

In the EU project “Albatross”, the Fraunhofer IWS has laser-assisted manufactured an innovative battery housing for electric vehicles and successfully demonstrated it in real component size. The lightweight structure combines extruded aluminum profiles with five-millimeter-thick die-cast aluminum parts.

Conventional processes reach their physical limits with this material combination: Die casting tends to form pores, while aluminum extrusion profiles of material group 6000 are considered sensitive to hot cracking. “Our solution is based on targeted oscillating beam guidance, which sets the molten pool in motion, reduces pores and at the same time produces metallurgically stable seams,” explains Dr. Jahn. “This allows us to produce high-quality aluminum welded joints without the usual use of filler material.” The battery housing was implemented and tested in a real vehicle model. In the Fraunhofer lighthouse project “FutureCarProduction”, this technology is currently being further developed with regard to the welding of secondary aluminum and cast-to-cast joints and subjected to a sustainability assessment.

René Jungnickel/Fraunhofer IWS

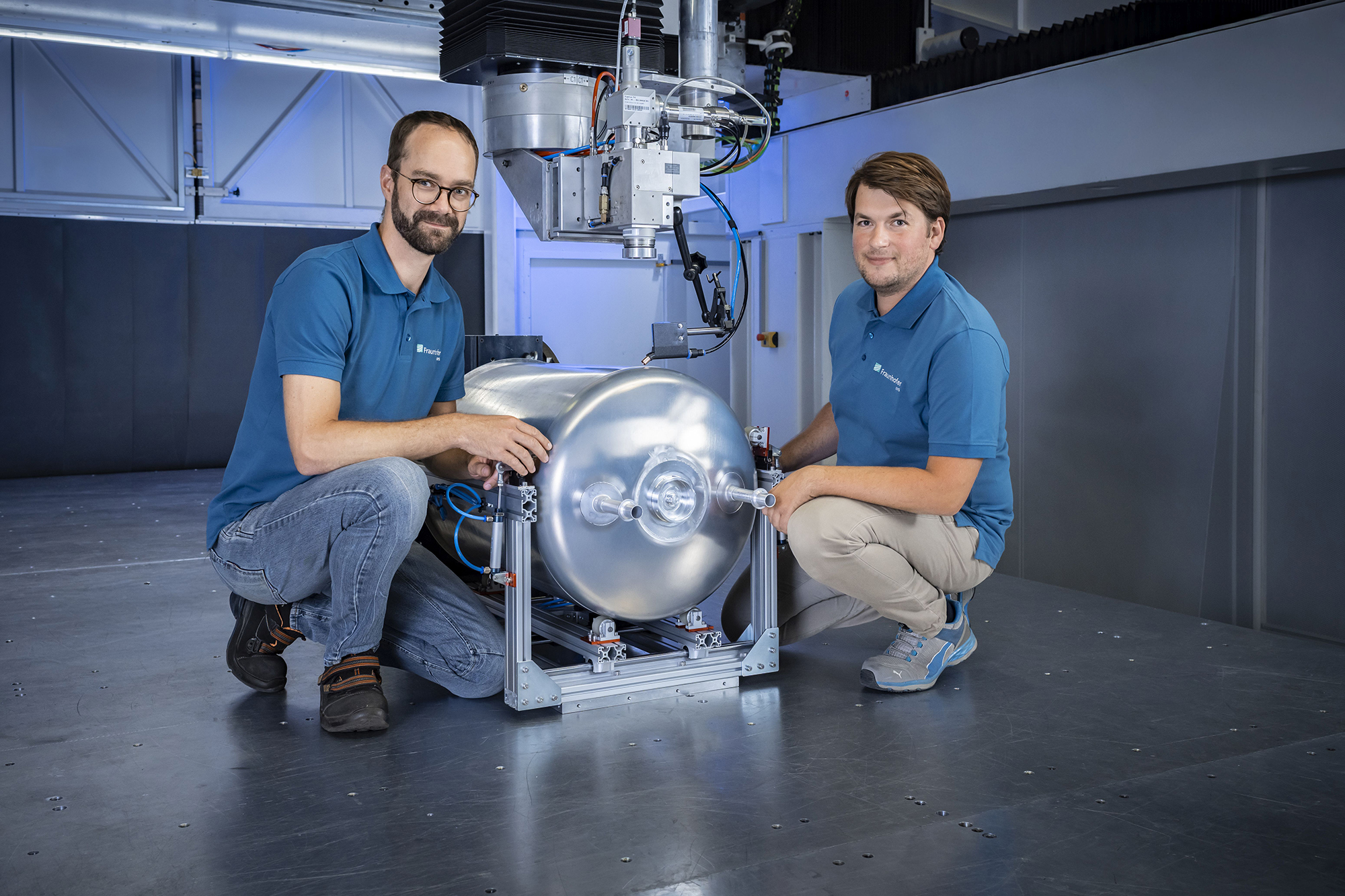

3D tank bottom: Crack-free weld seams for demanding operating conditions

For aerospace applications, the Fraunhofer IWS has developed a laser welding technology to produce closed tank structures from a high-strength aluminum alloy of the 2000 series. Since these alloys tend to form hot cracks during welding, filler wire is usually used to influence the alloy formation in the weld metal. The institute’s new laser welding process, on the other hand, completely dispenses with filler materials and enables process-stable, low-heat welding, even on three-dimensionally shaped contours. “The laser-based process is ideal for sealing rotationally symmetrical containers and is also being investigated for welding pipes,” says Dr. Jahn. “It delivers tight, mechanically resilient seams without significant distortion and with high seam strength.”

The process was developed as part of an aerospace project (LuFo) funded by the Federal Ministry of Economics and Climate Protection (BMWK, now: BMWE). In addition to laser welding, the Fraunhofer IWS is also testing friction stir welding (FSW) for blanks and electromagnetic pulse joining (EMP) of pipe connections in metallic mixed construction.

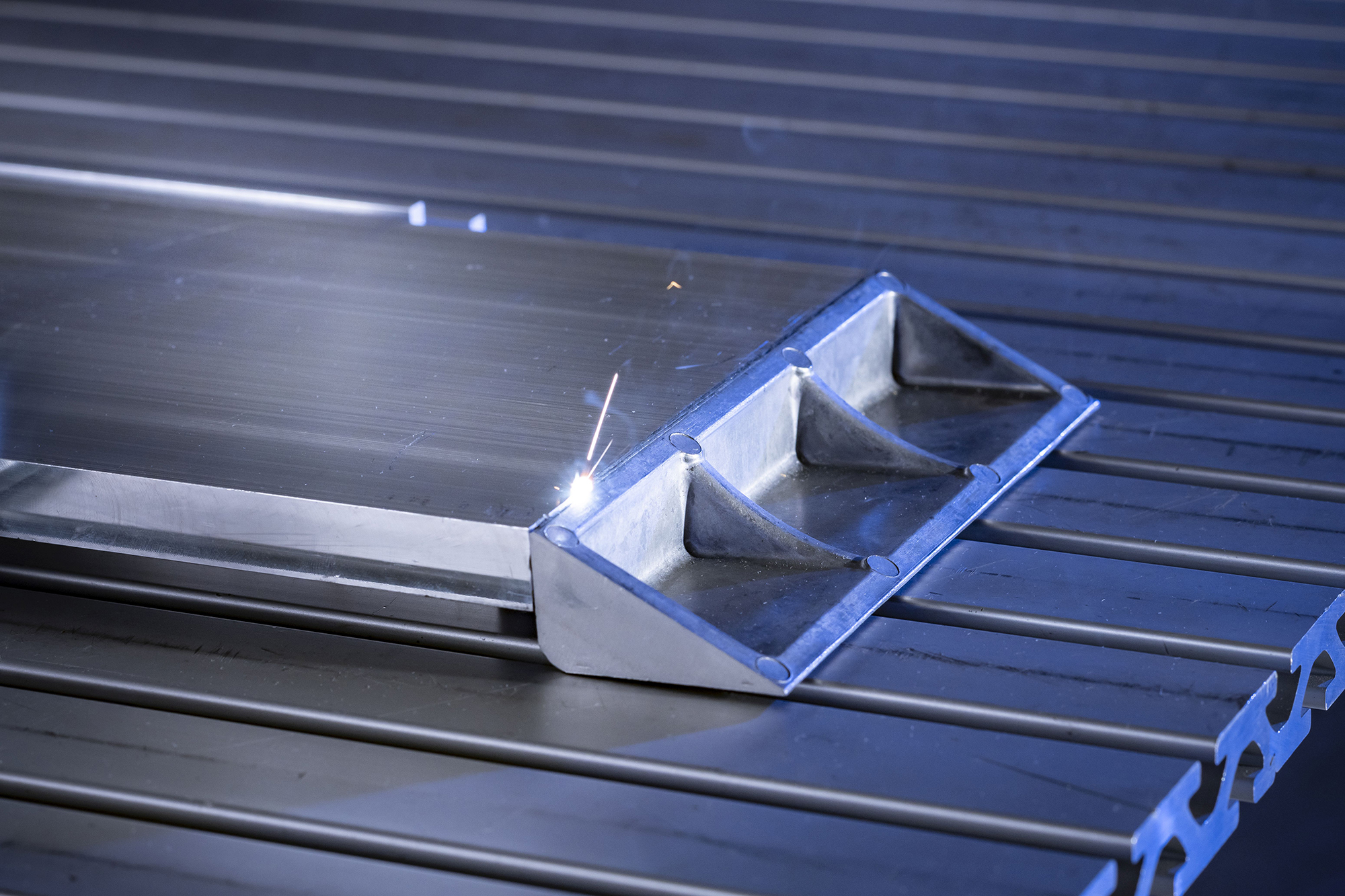

Crane jib: productivity boost for steel construction

Using the example of a four-metre-long crane jib, manufacturers of large-format steel constructions receive a new solution for the low-heat, resource-saving and reliable joining of solid steel profiles with wall thicknesses of over 20 millimetres in high quality. The core is a powerful multi-layer welding process with a maximum laser output of 24 kilowatts in a single clamping operation. The V-seam preparation has been optimized to an opening angle of less than five degrees. “This allows us to reduce the seam volume, save up to 90 percent filler material and largely avoid distortion,” says Dr. Jahn, describing the effects. “Straightening large assemblies – often an energy-intensive, manual work step – becomes superfluous in many cases.”

The development was funded by an SAB project and is also set to be used in bridge construction, wind energy technology and shipbuilding in the future. Initial industrial feedback confirms great interest in integrating the technology into existing production lines.

René Jungnickel/Fraunhofer IWS

Laser, material and system from a single source

The exhibited demonstrators show how materials science know-how, process engineering experience and systemic implementation can be successfully interlinked. The Fraunhofer IWS not only develops joining processes, but also supports their transfer to practical manufacturing environments. “We bring our solutions into application with coordinated sensor technology, sophisticated control and accompanying evaluation of process quality,” summarizes Dr. Axel Jahn.

Material and laser with system

The Fraunhofer Institute for Material and Beam Technology IWS develops complex system solutions in laser and materials technology. The researchers see themselves as idea drivers who develop solutions with laser applications, functionalized surfaces as well as material and process innovations – from easily integrated individual solutions to cost-efficient solutions for medium-sized companies and complete solutions suitable for industrial use. Research focuses on the aerospace, energy and environmental technology, automotive, medical technology, mechanical engineering and toolmaking, electrical engineering and microelectronics as well as photonics and optics sectors. In the five future and innovation fields of battery technology, hydrogen technology, surface functionalization, photonic production systems and additive manufacturing, the IWS is already creating the basis for the technological answers of tomorrow.