Clever material handling, automated sawing and storage: Kasto will be demonstrating at Emo how metal processors can make their material flow more efficient and increase productivity.

© Kasto

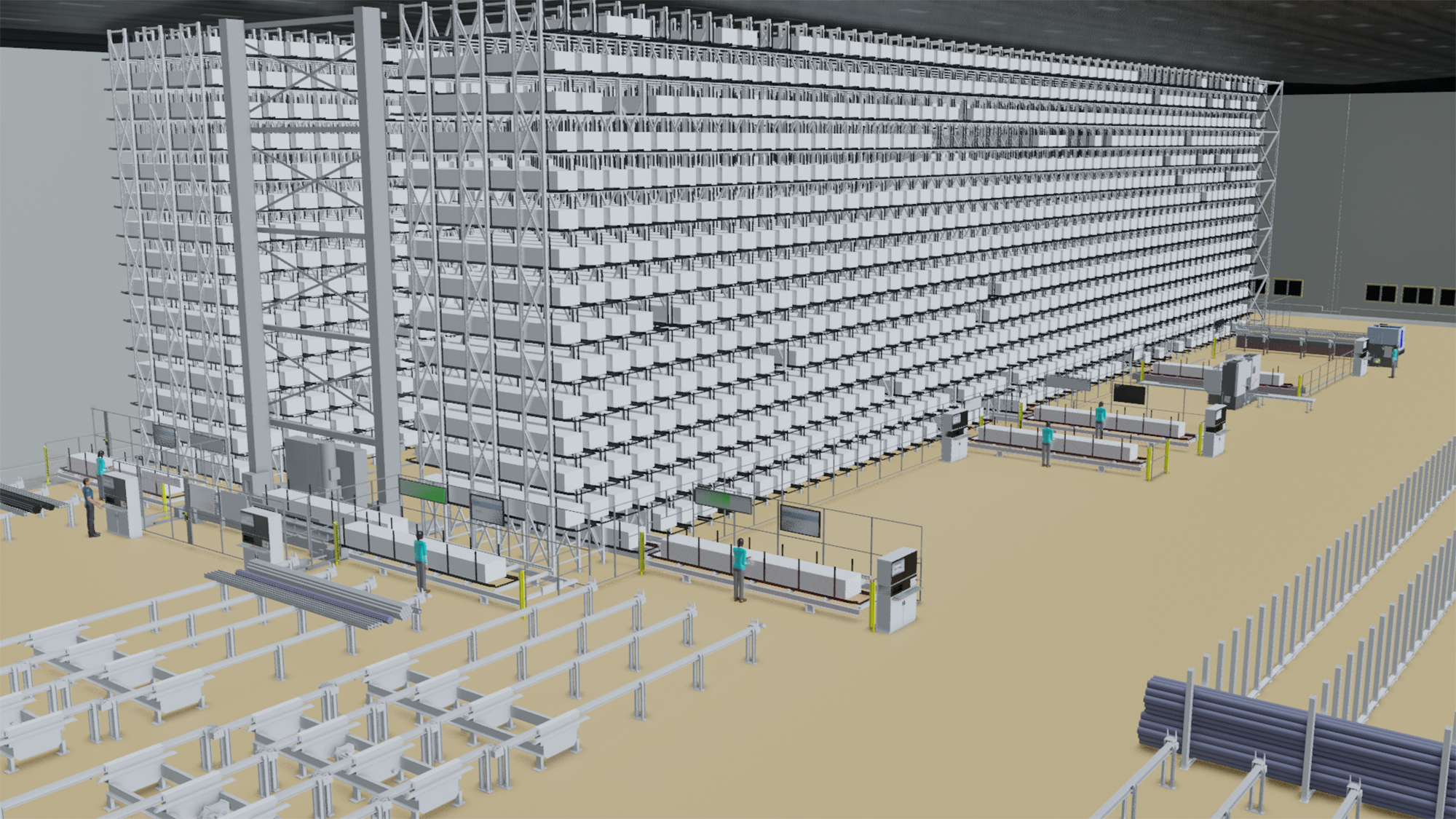

Material handling in the metal industry requires sophisticated systems along the entire value chain. Kasto, a specialist in sawing, storage and more, offers a comprehensive portfolio of solutions that optimize every step, from goods receipt to dispatch.

Kasto lays the foundation for a smooth material flow in the sheet metal sector right from the incoming goods department. Kastoflow Unpack solves the problem of manual sheet metal unpacking: the drum-shaped turning device turns packages of up to five tons through 180° so that strapping, film and wooden pallets can be removed effortlessly. Vertical and horizontal pushers then align the trays precisely – a decisive advantage for subsequent automated storage.

Increase throughput

Kastoload optimizes the material feed directly at the sawing machines. For example, a cross-moving double roller conveyor minimizes non-productive times: While one side serves the active sawing process, the other carries out preparatory tasks in parallel. On the outfeed side, a system automates material handling after the cut. A circulation sorting device picks up Euro pallets and material containers, while a lifting system brings the pallets precisely into the transfer position.

© Kasto

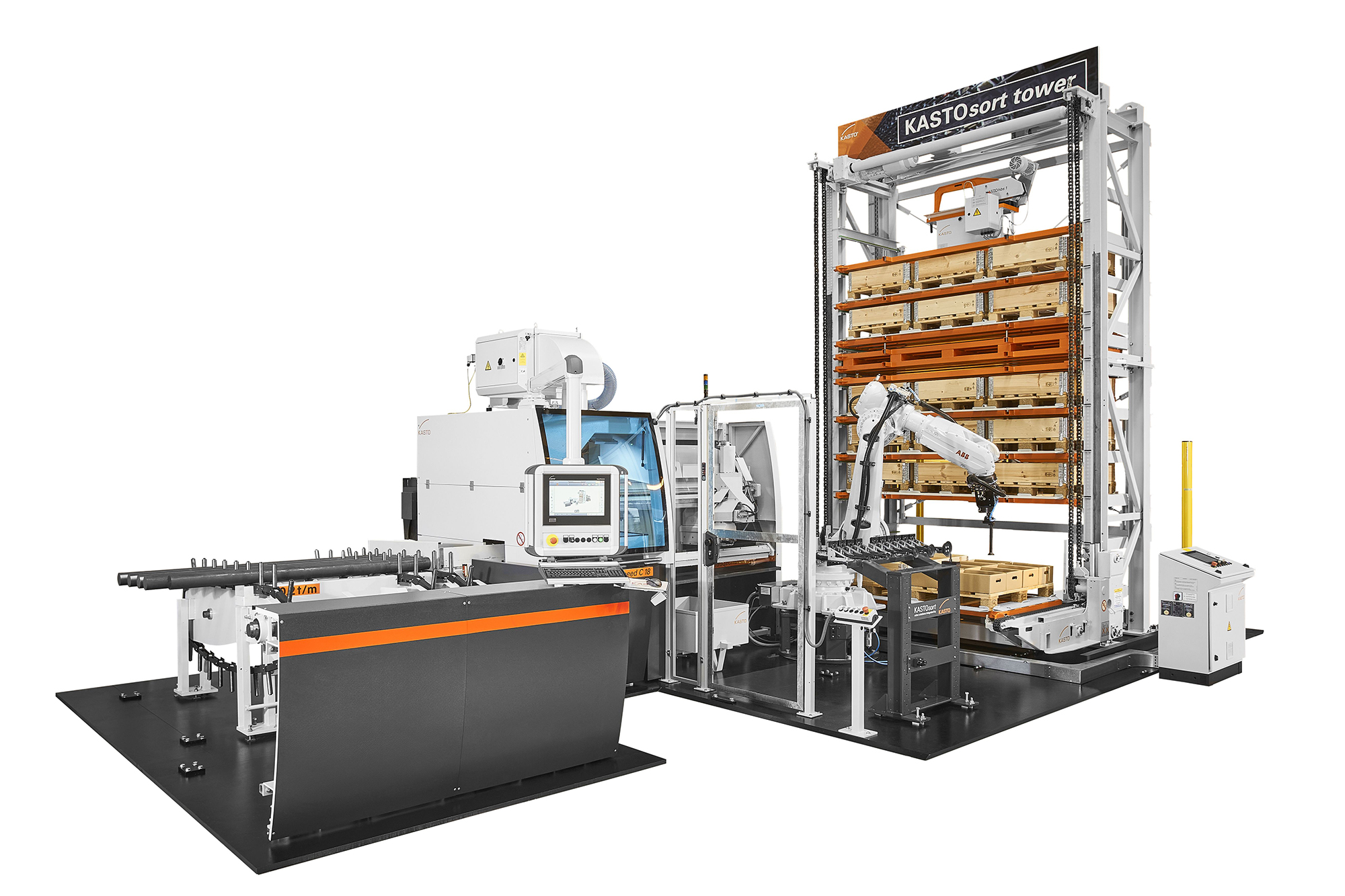

The Kastosort robot systems are designed to offer “automation in perfection”. They palletize and pick completely independently – without teach-in or programming by the user. The robot automatically calculates the optimum stacking pattern with maximum packing density. Particularly impressive: the Kastosort Tower automates the entire sawing and storage process in 24/7 operation in the smallest of spaces. This complete solution was named “Product of the Year” in 2024. The space-saving tower storage system automates sawing, sorting and storage in one compact system. It offers a high density and users can access the stored goods flexibly, around the clock and without personnel via a drive-through station.

Smart sawing

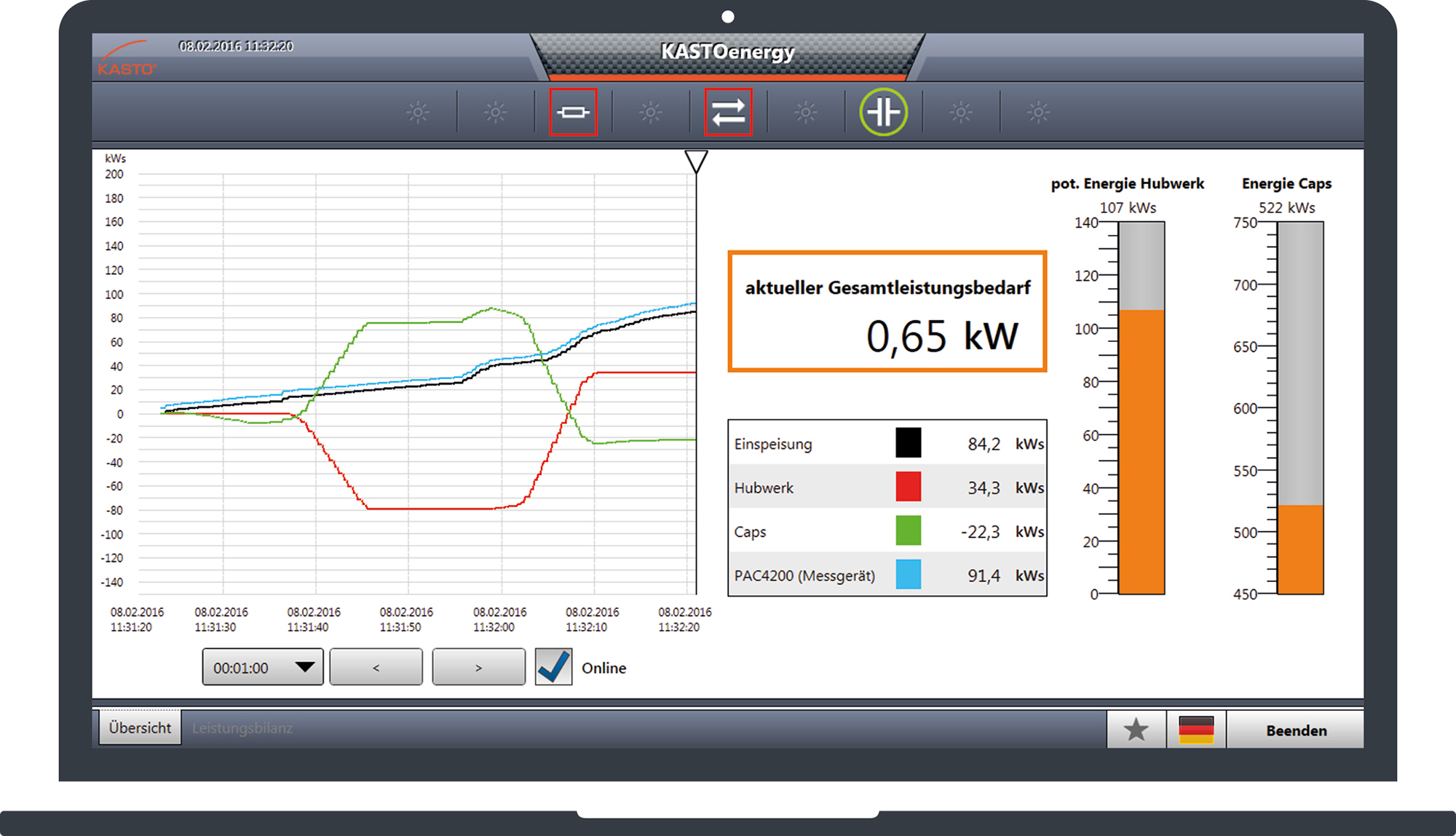

Kasto also shows how intelligent sawing works today: with powerful machines such as the Kastowin, the Kastomicut and the Kastotec power package for large cutting areas. There are also clever software solutions that automatically optimize straight and mitre cuts in the Kastologic WMS or adapt the feed speed to the material and cross-section without sensors. The saws can be seamlessly integrated into existing systems via open interfaces such as OPC UA or MQTT. The first models with the new, even more user-friendly and high-performance generation of the Kasto ProControl and ExpertControl control systems will be launched at the turn of the year. New features include a “Simple Mode” and many practical functions. Intelligent sawing means: higher performance, less effort and machines that think for themselves.

© Kasto

Kasto proves that sawing, storage and material handling is more than just cutting and transporting – it is a digitally networked process. The integrated system solutions optimize interfaces, reduce downtimes and create the basis for Industry 4.0 concepts. Companies benefit from a single point of contact for the entire material flow chain. And, of course, existing solutions can also be brought up to date.

Emo Hall 17, Stand C54

Web:

www.kasto.com