Company

Exhaust gas analysis on electric arc furnace

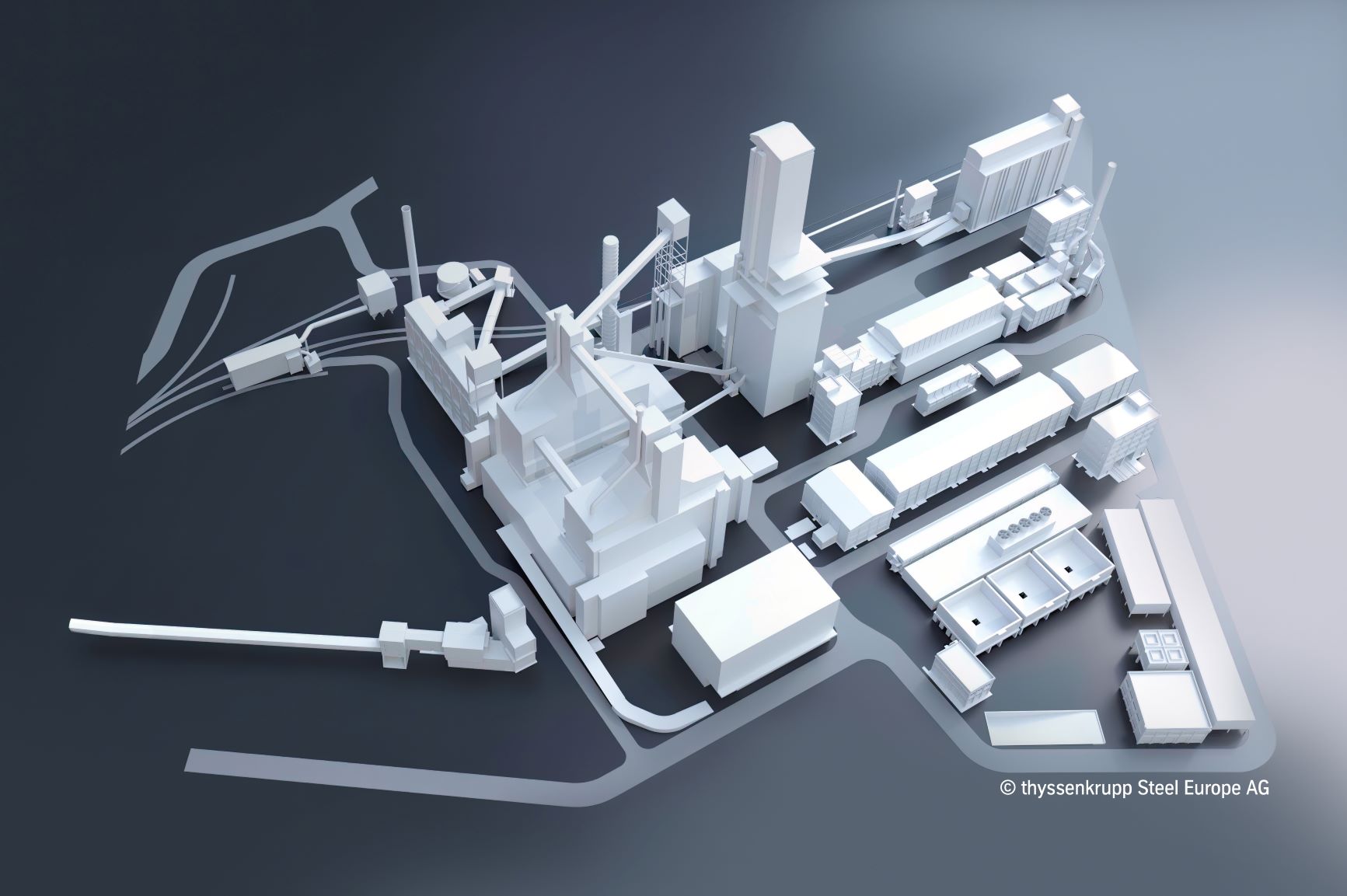

At AISTech/Metec in mid-June in Düsseldorf, Promecon will present the McON-IR system for rapid in-situ measurement of the composition and quantity of exhaust gas from electric arc furnaces. With the […]