Polytec will present the new Laser Surface Velocimeter ProSpeed LSV-1100 at Metec in mid-June in Düsseldorf. With enhanced connectivity and easy integration into process control, the company is raising the system to the same technological level as its big brother, the ProSpeed LSV-2100. By measuring speed and length, it increases the quality of the belts, as well as material efficiency and output – for example, in mass flow control or cut length optimization.

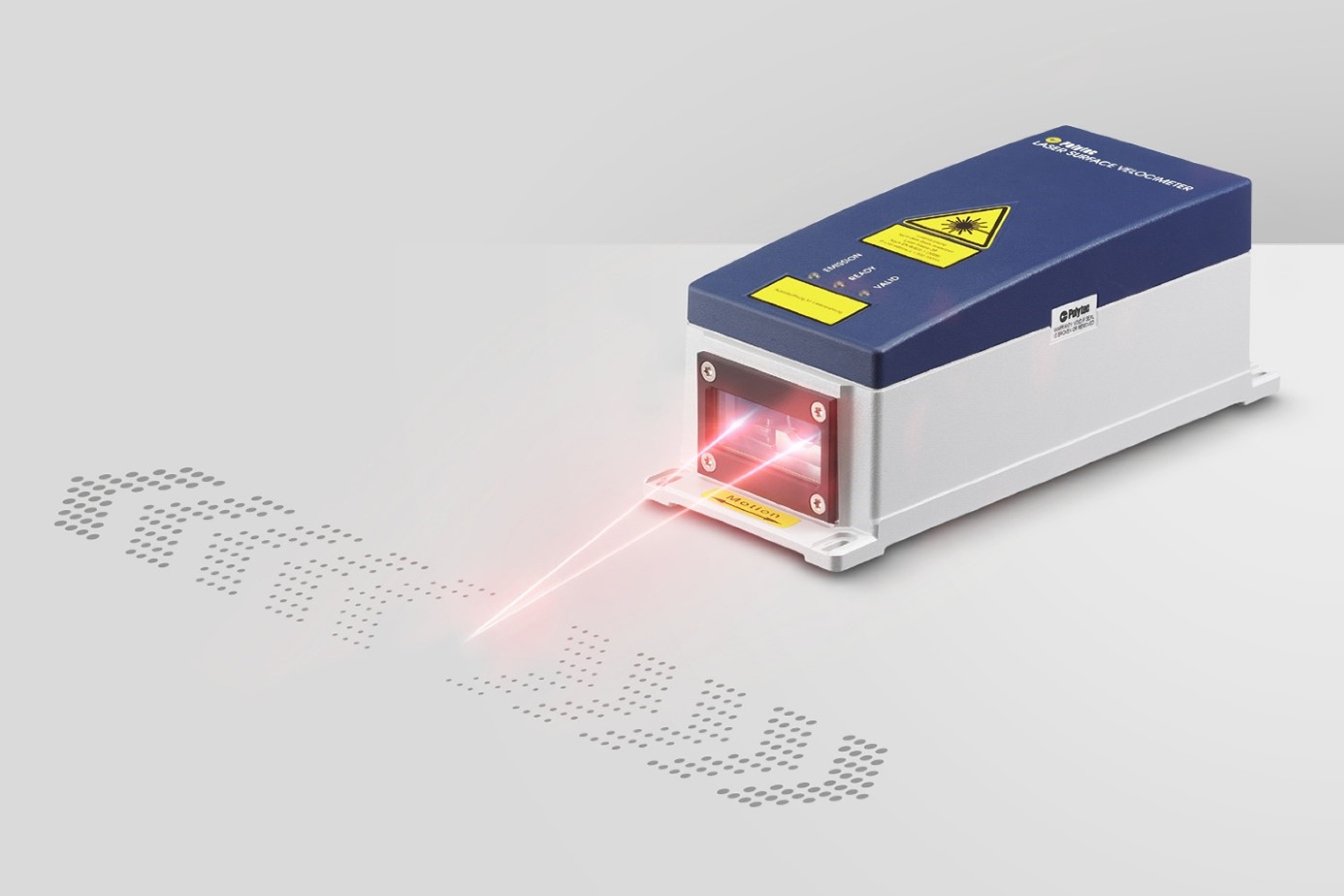

© Polytec

The ProSpeed LSV series surface velocimeters provide highly accurate speed and length data in rolling mills and strip processing lines for process control and optimization.

Polytec has now equipped the new ProSpeed-LSV-1100 with the same connectivity as the larger ProSpeed-LSV-2100, which allows for a greater working distance, among other features. Thus, both systems now have several interfaces that make integration into modern process control environments easy, for example via Profinet or Ethernet. The wide range of interfaces also supports plant engineers in integrating the system into a wide variety of environments anywhere in the world.

The measured values can now be shown on any display in control stations via a WLAN module and can be parameterized and maintained very easily via a web interface. Up to four users can access the system simultaneously.

By transferring the high connectivity standard of the ProSpeed-LSV-2100 to the ProSpeed-LSV-1100, Polytec makes operation and maintenance easier because all systems in one plant are on the same technological level: operation and maintenance are identical – a clear advantage for users operating equipment from both series.

Robert Bodamer, the product manager at Polytec, sees clear advantages for his customers in the standardization of functions: “Both systems now only differ in their application. The ProSpeed-LSV-2100 additionally offers detection of direction of movement and standstill, and it also enables a working distance from the pass line of up to three meters.”

One example of process control with surface velocimeters is Automatic Gauge Control (AGC) on rolling mills. There, the speed measurement is a decisive input value for the fast and precise control of the roll gap. This allows users to achieve the specified strip thickness very quickly after threading the coil – and thus over a larger proportion of the strip – than without control.

Web:

www.polytec.com