Customers with older AP&T production equipment are encouraged to have their machines inspected and upgraded to ensure future operations.

contain components and systems that will soon be obsolete. Therefore, AP&T can no longer guarantee access to spare parts or support. Any unplanned downtime can then lead to significant and costly production disruptions.

Lower risks – higher performance

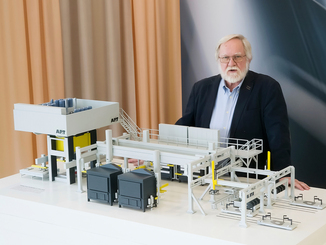

Giving AP&T the opportunity to replace old equipment, check critical components and optimize functions is a simple way to future-proof its solution and adapt it to its needs. In addition, this allows the operator to increase its production capacity and productivity.

As a one-responsible partner, AP&T can take care of everything from individual machines to complete lines, including the following:

– Updating the HMI, protective devices and safety equipment.

– Replacement of control systems and overhaul of hydraulic pumps, seals and bearings

– Updating of destackers and replacement of feeders, shuttles and grippers

– Service agreements, process optimization and installation of new products in existing lines

To take advantage of this offer, AP&T customers should contact their local AP&T contact person.

Web:

aptgroup.com