Contacting copper wire windings in electric motors, additive manufacturing of electronic components, recycling-oriented separation of solder joints: Laser solutions for these and related challenges in the field of copper material processing will be presented by diode laser specialist Laserline at Coiltech 2025 (March 26 and 27) in Augsburg.

Laser solutions for the production and recycling of copper-based electronic components – this is the focus of Laserline’s appearance at Coiltech Deutschland 2025 (March 26-27 in Augsburg, stand 5-H22). The main topics will be the contacting of copper wire windings in electric motors, the additive manufacturing of electronic components and the recycling-oriented separation of soldered connections. In addition, the industrial laser specialist will be providing information on the diverse possibilities of copper material processing using blue diode lasers.

Stripping and contact welding of copper wire windings

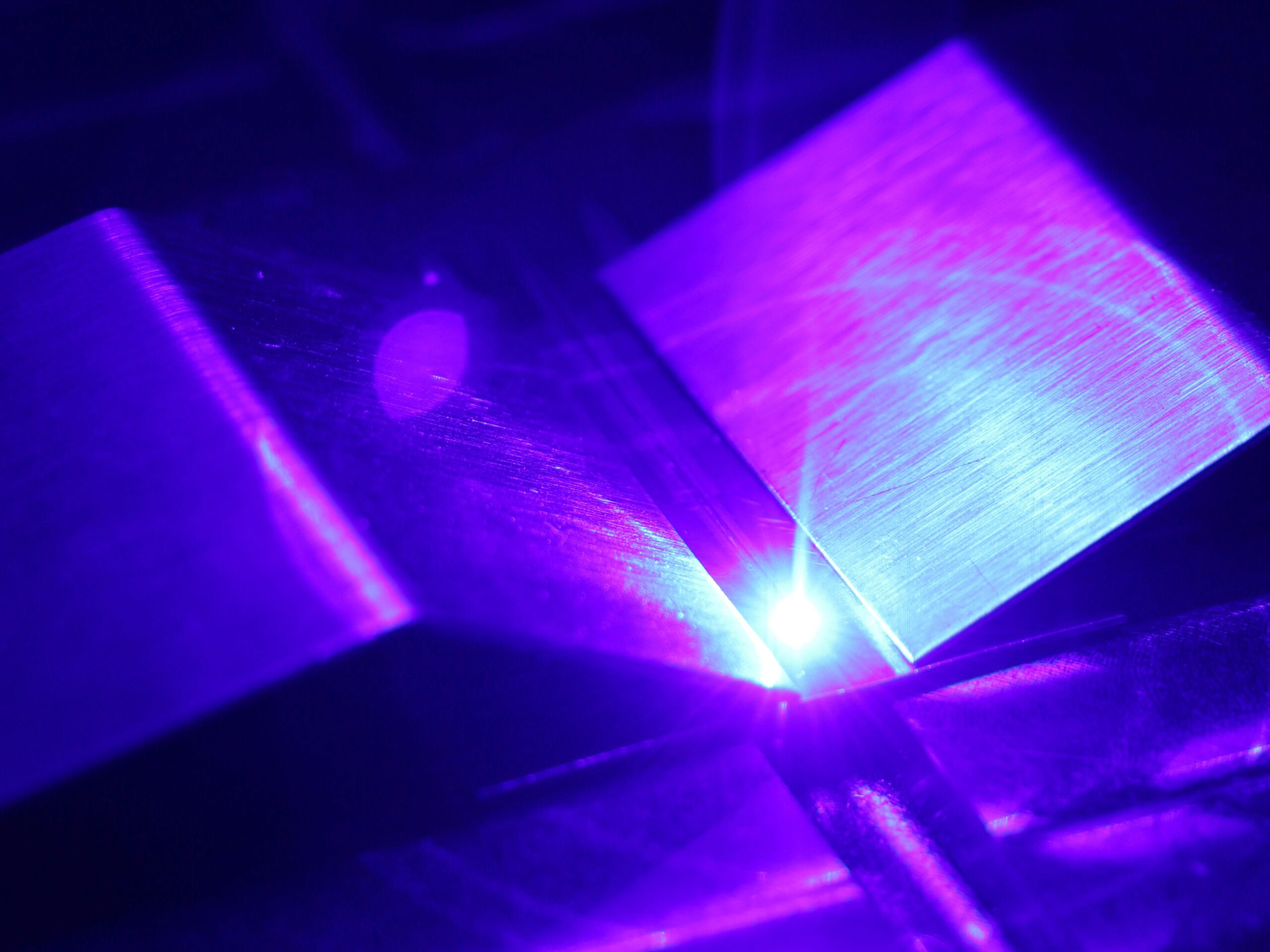

For electrical contacting – of electric motor coils, for example – Laserline is presenting system solutions for preparatory stripping in the joining area (wire stripping) and subsequent laser welding of the contacts (wire/poles connection). Both solutions are based on blue diode lasers with a wavelength of around 445 nm and are supported by high-precision beam shaping optics. In these system configurations, the excellent absorption of blue laser radiation in copper enables even very fine wires to be processed effectively and gently. Depending on the application, the beam sources operate with outputs between 400 W and 6000 W, with beam qualities of ≤4 to 60 mm∙mrad. On the beam shaping side, laser scanners are used for stripping, while scanners or fixed optics (OTS-5) with round spot are also used for welding.

Additive manufacturing of copper-based electronic components

The new blue high-brilliance lasers with WBC technology will be presented at the trade fair stand as a further manufacturing option for electronic components. With a beam quality of ≤ 4 mm∙mrad and output powers of 400 or 800 watts, the LDFblue 400-wbc and LDFblue 800-wbc diode lasers enable the additive manufacturing of copper-based electronic components using laser powder bed fusion in robust and spatter-free processes. They combine exceptional beam quality with a robust and industrially proven system architecture.

Recycled separation of soldered joints

With blue diode lasers in combination with flexibly adjustable OTZ zoom optics, Laserline will also be presenting system configurations for the separation of soldered copper connections by applying heat, as can be used for the recycling of copper busbars or other copper-based electronic components. The system solutions can be used for the separation of soldered and brazed joints (de-soldering and de-brazing); the associated zoom optics enable large-area, individually adjustable spots with a homogeneous intensity profile (top hat), which are very well suited for the uniform heating of the joining zones.

Lecture on blue diode lasers as a multi-tool for copper material processing

The trade fair appearance will be rounded off with a presentation entitled “Blue Diode Lasers: A Multitool for Processing of Copper”. Dr.-Ing. Luisa-Marie Schäfer-Heine, product expert for blue diode lasers at Laserline, will provide information on the many possible applications of blue diode lasers in industrial copper material processing.

Background

Laserline GmbH, based in Mülheim-Kärlich near Koblenz, was founded in 1997. The company is one of the world leaders in the development and manufacture of efficient, modular diode laser systems with blue and infrared wavelengths. Laserline high-power diode lasers achieve output powers of up to 60 kW and an electrical efficiency (WPE) of over 50 percent. Based on decades of experience, Laserline develops customized laser solutions for industrial applications – including high-quality beam shaping optics for the realization of variable spot geometries – and has established itself internationally as a reliable partner. More than 7,500 high-power diode lasers from Laserline are currently in use around the world, demonstrating their performance in a wide variety of processes and applications. The laser technology specialist currently employs around 400 people and has international subsidiaries in the USA, Mexico, Brazil, Japan, China, South Korea and India as well as representatives in Europe (France, Great Britain, Italy) and the Asia-Pacific region (Australia, Taiwan, Singapore).

Web:

www.laserline.com