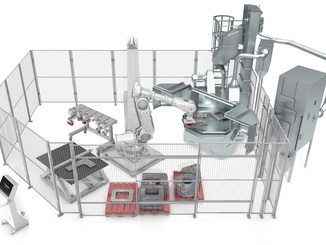

UnionStahl now grinds flame-cut parts fully automatically – without programming – using the EasyGrinder from Teqram. This not only saves time and personnel, but also reduces physically strenuous work and increases processing quality at the same time. The use of the EasyGrinder complements existing automation solutions and takes post-processing to a new level.

UnionStahl is one of the largest steel traders and flame-cutting companies in Europe. With a stock of 60,000 tons and an annual processing capacity in the four-digit ton range, numerous flame-cut and plasma parts are produced every day that have to be cleaned before shipping or further processing. The majority of these are already processed automatically – quickly, reliably and without manual programming.

© Teqram

Pioneer of automation

UnionStahl implemented the first automation solutions from Teqram six years ago. Since then, two continuous deburring systems from Arku have been loaded and unloaded automatically – with workpiece weights of up to 200 kg and cycle times of just 25 seconds. Subsidiaries also rely on Teqram technology, for example for unmanned, double-sided blasting of components.

Precise post-processing for complex requirements

Since the beginning of 2025, the EasyGrinder in Duisburg has supplemented the automated processing. The robot takes over the fettling of components where conventional throughfeed systems reach their limits – for example when removing chamfer flags, grinding hardened narrow sides or applying chamfers.

© Teqram

Several work steps combined in a single process

The EasyGrinder reduces physically strenuous activities such as manually lifting and placing heavy parts. In addition, several processing steps can be combined in an automated process: Slag removal, deburring, grinding, stamping, lowering, chamfering – even blasting can be integrated. This eliminates the need to pick up the parts several times and makes manual reworking virtually superfluous.

Plastering bottleneck eliminated: Automated instead of overloaded

Finding and retaining suitable specialist staff for plastering work remains a challenge. High staff turnover can lead to bottlenecks – reworking is often a real brake on production. The EasyGrinder provides a remedy here: processing can be planned and qualified personnel can be shifted to more value-adding areas.

Growing together: the community as a driver of innovation

Ulrich Stumpf, head of cutting operations at UnionStahl, sees a particular advantage in the close cooperation with the Teqram community: “All existing customers benefit from all further developments, as the software and the range of functions are constantly growing.”

Functions such as stamping or applying chamfers were not available five years ago – today they are part of the standard repertoire. Existing customers receive these enhancements via free software updates. If an additional tool is required, it can be easily retrofitted – the solution grows with the requirements.

© Teqram

An investment that pays off – backed by strong service

After half a year of productive use, UnionStahl can draw a clear conclusion: the investment in the EasyGrinder has paid off. The reliable support from Teqram is particularly emphasized: “And the service is also simply outstanding – that has to be said – you rarely find anything like it,” says Ulrich Stumpf. Teqram solutions are already being used successfully in several locations and are regarded as an integral part of modern machining processes.

Technology as the key to competitiveness

With the introduction of the EasyGrinder, UnionStahl is sending a clear signal for the consistent expansion of automated processes in steel processing. In a market environment characterized by a shortage of skilled workers and increasing cost pressure, intelligent robotics such as those from Teqram offer a sustainable contribution to the future viability of medium-sized industrial companies.

Web:

www.teqram.com