Thanks to the Easygrinder, Minerd & Sons was able to reduce the delivery time from two weeks to just three days. The steel service center in Pittsburgh, Pennsylvania, has significantly accelerated the finishing of plasma and oxy-fuel cut sheet metal parts by using Teqram’s autonomous grinding robot. The system processes thick sheet metal fully automatically, without programming or teaching.

Minerd & Sons processes several thousand tons of sheet steel every year for customers in the mechanical engineering, construction and heavy machinery industries. The quality of thermally cut edges is crucial for weldability, coating quality and further processing. Until recently, edge cleaning and reworking was a laborious manual process that tied up skilled workers. “Ready-to-assemble components require flawless edge quality – and manual grinding was increasingly becoming a bottleneck,” says Mark Minerd, President of Minerd & Sons.

© Teqram

Automation as the answer to skills shortages and process stability

With the Easygrinder, this process step is now covered automatically for many component geometries. The throughput increases, while at the same time the pressure on the labor market is reduced.

“Our aim was to relieve qualified employees of monotonous and strenuous work and deploy them for more value-adding tasks,” says Minerd. “This not only improves safety, but also the working conditions of our team in the long term.” According to Teqram, the process quality also increases: “The system delivers a consistently reproducible edge quality – for every single part. This level of consistency is almost impossible to achieve manually.”

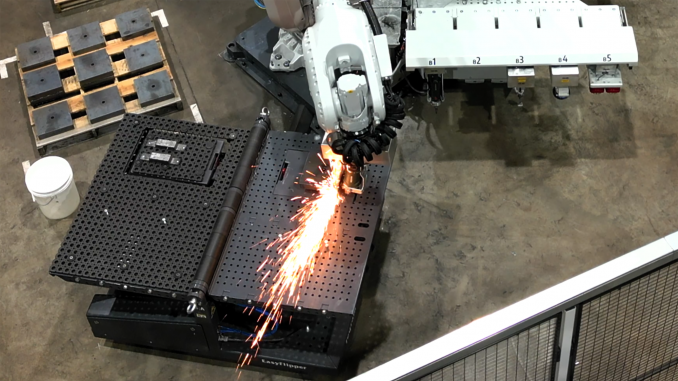

A comprehensive evaluation process strengthened confidence in the Easygrinder. “Initially, we had concerns about the necessary monitoring,” reports Matt Minerd, Work Order Manager. However, Teqram has shown that the Easygrinder is a tried and tested production system. “In contrast to classic flatbed grinding machines, the Easygrinder processes internal and external contours equally efficiently,” he adds.

Intelligent and flexible edge processing

© Teqram

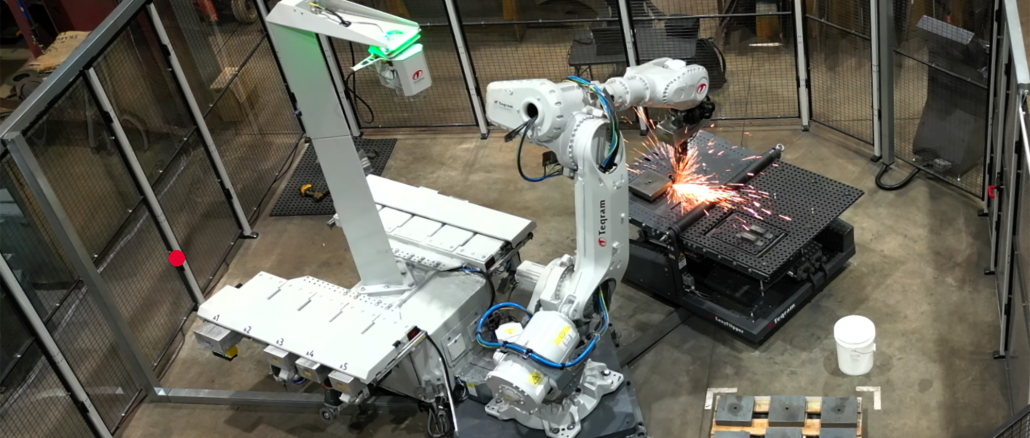

With the help of 3D vision technology and an AI-based control system, the system automatically recognizes the geometry of each component and selects the optimum processing strategy itself. Heavy slag is removed, sharp edges are broken and profiles are rounded – for example with a constant radius of 2 mm for coating adhesion. At the same time, cut surfaces are cleaned and the heat-affected zone is removed.

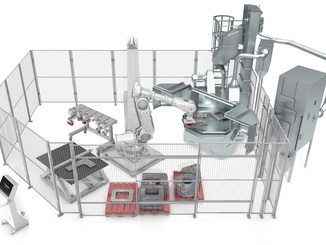

Operation remains simple: employees place pallets with raw parts in the work area. The robot takes over handling, processing and destacking autonomously.

To further increase throughput and delivery performance, Minerd & Sons relies on unattended night production. Mark Minerd says: “Lights-out grinding is the equivalent of an extra shift – without any additional staff.”

The collaboration with Teqram is also seen as a success factor. “The time difference is an advantage for us,” explains Minerd. “We report an issue during the day and the next morning we already have a solution.” With the Easygrinder, Minerd & Sons is consolidating its position as a pioneer in the industry – through quality, occupational safety and process efficiency.