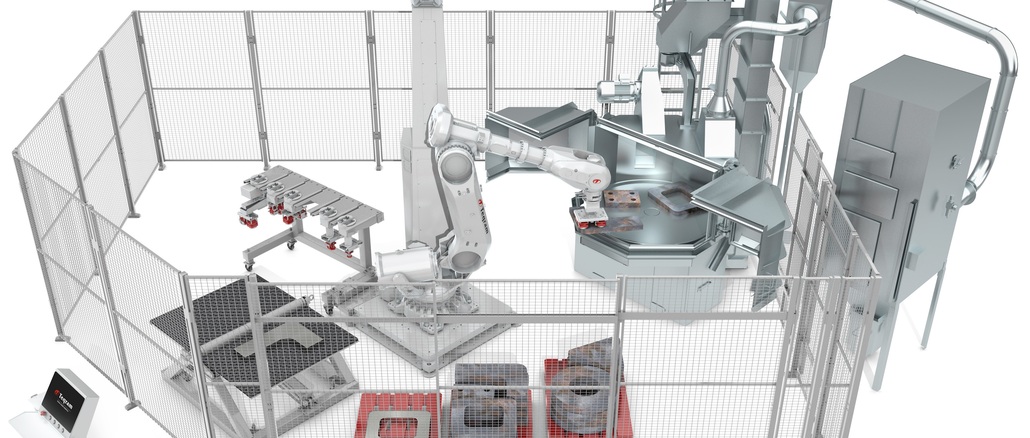

During EuroBlech, Teqram will introduce the EasyShotblast. It can be used to load and unload blast machines completely unmanned. By automating the blasting process, quality can be significantly increased while energy and personnel costs are drastically reduced. Thanks to vision technology, programming or teaching is completely eliminated.

Shot blast machines are used when the surface finish or roughness must meet certain specifications. The parts are often heavy and manual loading of the blast cabinet with a crane or lifting aid is extremely labor intensive. With the EasyShotblast, Teqram offers a solution for automatic blasting of plasma and oxyfuel cut parts up to 200 kg, optionally up to 500 kg.

© Teqram

Fully autonomous without programming or teaching

Simply place the pallets with the parts to be processed in the working area of the robot and press “Start”! That’s how easy it is to operate the EasyShotblast. Pallets, stacks and blanks are automatically detected by the EasyEye 3D vision system in combination with an artificial intelligence-based control system. The selection, positioning and changing of the grippers for picking up different products and depositing them in the blast cabinet is also fully automatic, without lengthy programming or teaching. As a result, EasyShotblast enables cost-effective automation of individual parts or small batches.

“With EasyShotblast you increase your quality. Narrow sides are perfectly finished and there are no shadows from belts or baskets on the underside,” promises Teqram. Energy consumption is up to 75 percent lower and the short cycle times result in higher output, he said. This means that the payback period for EasyShotblast is often less than 2 years.

Better working conditions

It is becoming increasingly difficult to find and retain good skilled workers. The EasyShotblast improves the ergonomics around blasting. The robot takes over the heavy and repetitive work.

Automatic turning can be easily integrated for two-sided machining, as can additional machining steps such as deslagging, deburring or removal of focal noses. Cutting parts can thus be completely machined in one step.

EasyShotblast nominated for the EuroBlech Award.

With the EasyGrinder, Teqram has already won the BlechExpo Innovations Award 2021 and recently the TechniShow Innovations Award 2022. Now Teqram has been nominated for the EuroBLECH Award 2022 in the Automation and Handling category with the EasyShotblast. The winner will be determined by audience voting. The EuroBlech Award ceremony will take place on October 25.

Web:

www.teqram.com

Euroblech Hall 26, Booth L52