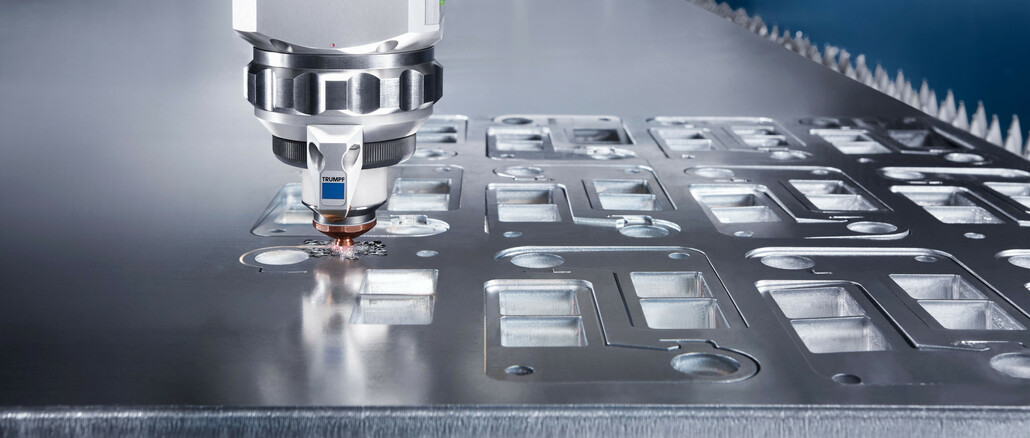

The new laser cutting machines of the TruLaser Series 5000 offer a whopping 12 kilowatts of laser power with the TruDisk 12001. Intelligent systems ensure process reliability as well as highly productive melting and flame-cutting operations

Trumpf, the machine tool specialist, has equipped the laser cutting machines in its new TruLaser Series 5000 with the TruDisk 12001 disk laser with 12 kilowatts of laser power. Thanks to intelligent assistance systems, the new machines achieve up to 50 percent higher feed rates in medium to high sheet thicknesses than conventional laser machines with a 10-kilowatt laser.

The throughput of cut metal sheets per hour can thus be increased by up to 20 percent. The new TruLaser Series 5000 is equipped with proven functions such as Active Speed Control or BrightLine Fiber, which support the cutting process during fusion and flame cutting. They guarantee a high degree of process reliability and improved part quality.

The productivity of the machine is crucial

Hendrik Meidert, product manager for the Trumpf TruLaser Series 5000, explains: “For us, it’s not just a matter of increasing the feed rate with a higher laser power and thereby saving some time during cutting. It is much more important that the sheet throughput and thus the overall productivity of the machine also increases. To achieve this, it is important to reduce or completely avoid unproductive downtime.”

Especially when cutting thick structural steel, problems can occur that slow down or stop the production process. For example, in the case of sheets with contamination, low material quality or thickness variations between individual sheets, the cut may break off. Time and material loss are the result.

“The higher the laser power and thus the productivity of the machine, the more serious are downtimes due to malfunctions. This can be prevented with intelligent assistance systems. Especially with high-speed systems such as the TruLaser Series 5000, we therefore rely on functions that offer safety during dynamic cutting,” says Meidert.

For the TruLaser Series 5000 with 12 kilowatt laser, all assistance systems are available that have already proven themselves in the machines with 10 kilowatt:

Automatic control of cutting speed

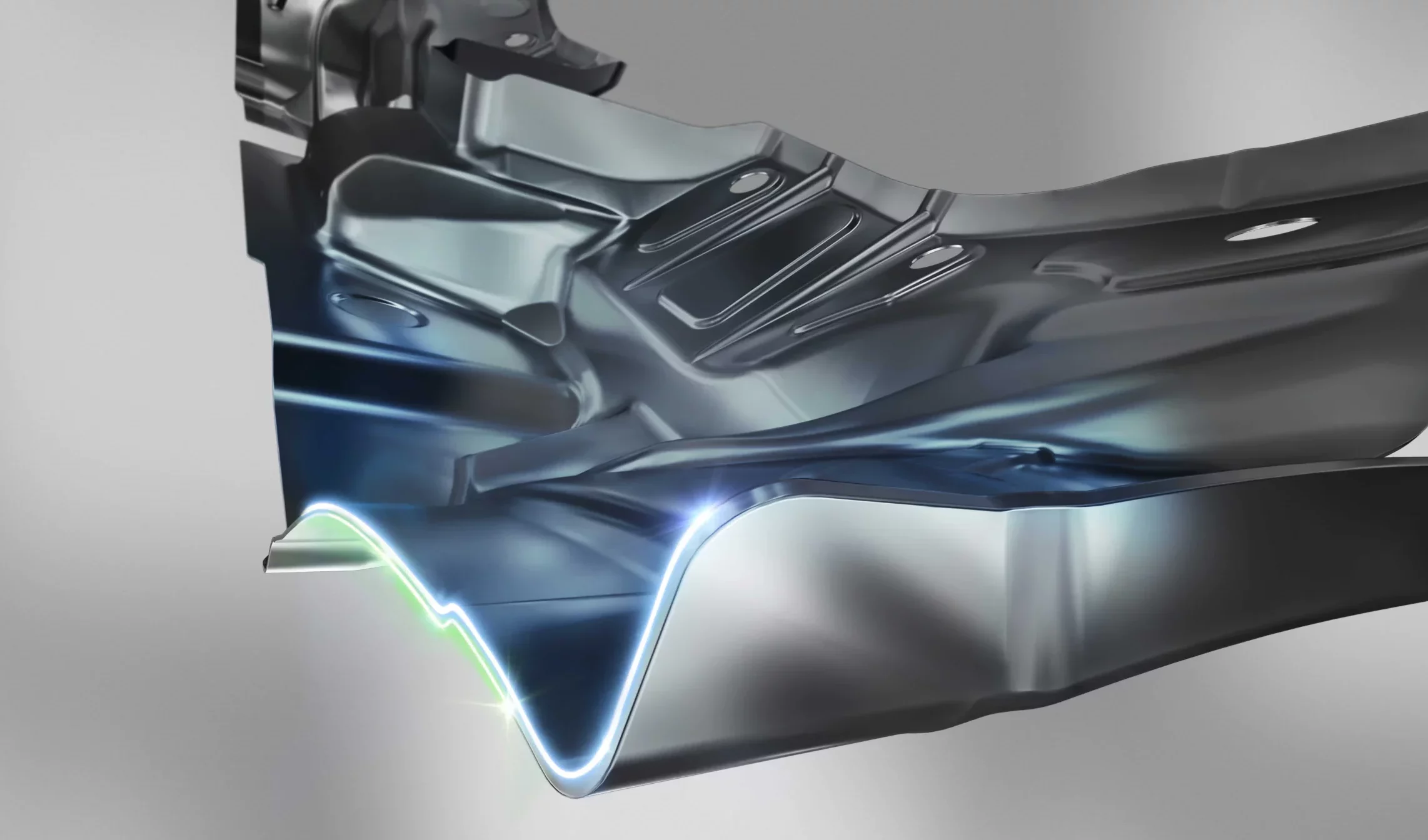

The first step towards autonomous laser cutting is the Active Speed Control cutting sensor system. Here the machine itself takes over the control of the laser cut. A camera looks through the cutting nozzle directly into the cutting gap in real time and observes the process light, i.e. the radiation produced during laser cutting. The changes there show whether the melt is coming out of the kerf correctly.

Based on the data, Active Speed Control automatically determines the fastest possible feed rate and adjusts it automatically if necessary. This compensates for fluctuations in process reliability and prevents the production of rejects.

tighten the sheets

A practical function when cutting thick material is the CoolLine function: a nozzle sprays water mist onto the cutting edge and cools the sheet. This prevents heat from accumulating and the quality of the cut from suffering. The cooling system makes it possible to use the sheet metal more tightly and also to cut filigree parts with process reliability.

Cutting less high quality sheet metal

Thanks to the BrightLine fiber function, it is possible to cut thick sheets with a large focus diameter. This widens the kerf and increases the quality of the cut edge. The large diameter stabilizes the cutting process so that fluctuations in material quality hardly affect the result. The parts are also easier to remove.

Inspect nozzle automatically

Comfort, safety and burr-free cutting are guaranteed by the Smart Nozzle Automation function. Even in fully automatic operation, the system inserts the correct nozzle and checks its quality. The nozzle changer can also be pulled out of the machine and set up during cutting, which avoids unproductive downtime.

The TruDisk 12001 is available for the TruLaser 5030 fiber, the TruLaser 5040 fiber and the TruLaser 5060 fiber.

Web:

www.trumpf.com