At Blechexpo, Roemheld presented several innovations that help to reduce set-up times in sheet metal forming and increase operational reliability.

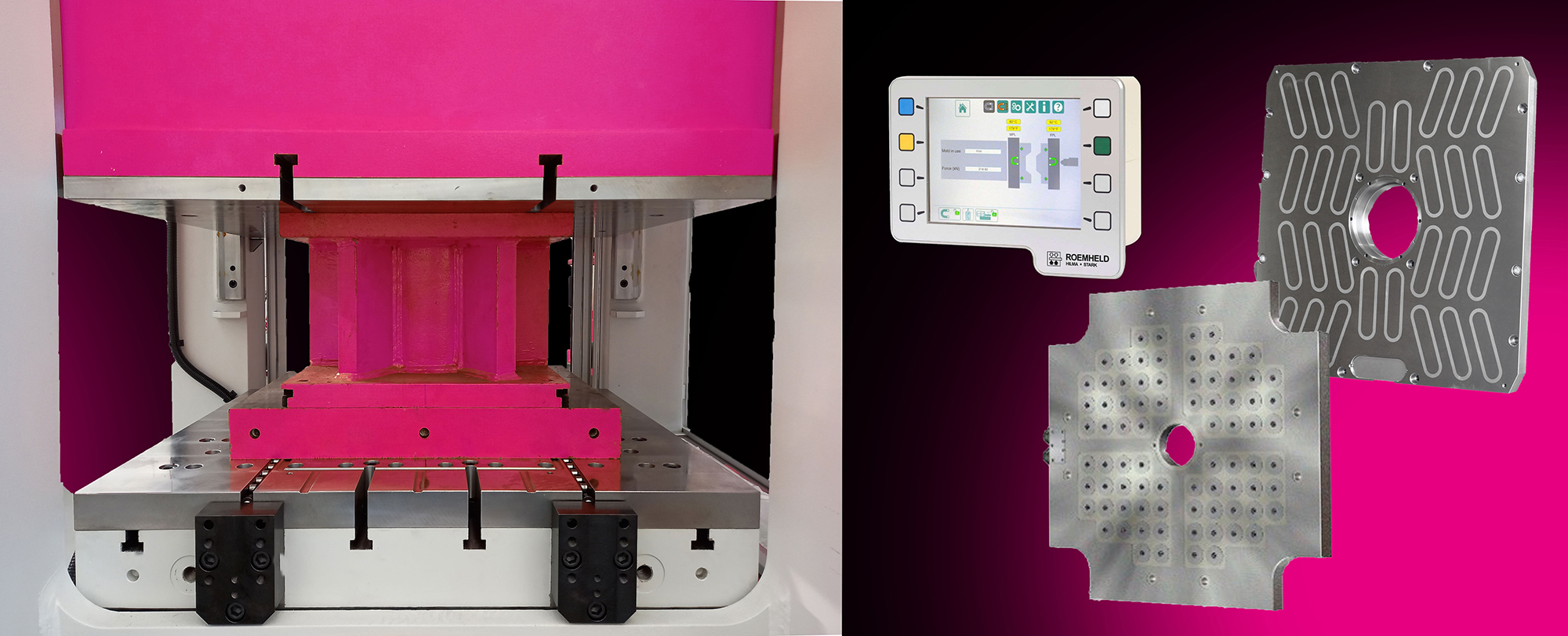

R-Mag-M, the supplier’s first own magnetic clamping system for sheet metal forming, celebrated its trade fair premiere. It is the first to offer a clamping force display and interchangeable magnetic poles. With both functions, which were requested by many customers, the clamping technology specialist claims to be unrivaled in sheet metal forming.

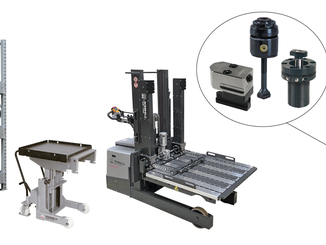

Two further electrically driven innovations facilitate tool transportation: an RW 1000-Elmo for tools weighing up to 1,000 kg and the RWT for loads of up to 4,000 kg.

The Flexline-R quick-clamping system for automatic clamping of tools of different sizes on the press ram will also be on show for the first time at a trade fair – as will the “Green Edition” version for 24 V DC voltage.

The first magnetic clamping system with clamping force display

The electro-permanent magnetic clamping system R-Mag-M clamps tools of different sizes and geometries fully automatically and distortion-free in seconds and guarantees a secure hold even in the event of a power failure.

A new feature is an integrated clamping force display for greater process reliability. In addition, various sensors such as temperature sensors, position switches and flux measurement sensors check the system during production. These control functions and high holding forces guarantee reliable tool clamping.

The interchangeable magnetic poles are innovative. The technology simplifies maintenance and reduces downtime to a minimum, as defective poles can be replaced on site. A modern 8-inch color display and an integrated remote maintenance module round off the new R-Mag-M. Roemheld designs and develops all customized magnetic clamping systems in Europe.

© Roemheld

Fully electric drive for more comfort

A new version of the RW 1000 series tool change trolley for load capacities of up to 1,000 kg extends the tried-and-tested model series with an all-electric variant. Unlike its manually driven siblings, both the stroke and the drive of the new RW 1000 Elmo are purely electric.

The “B” version is also available with an additional integrated docking bar in the front area. This bridges interfering edges on the press table, making it easier to move the tools onto the machine table.

Heavy-duty specialist: Tool changing trolley up to 4,000 kg

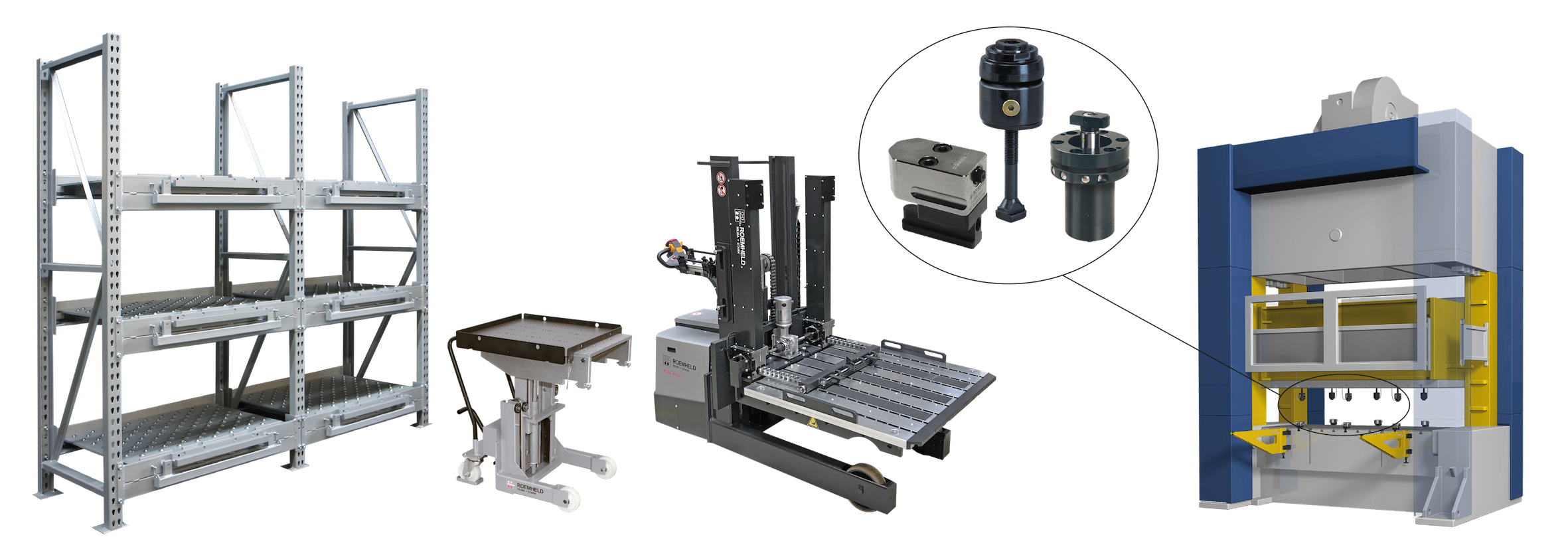

For particularly heavy loads, Roemheld is presenting the new RWT tool changing trolley at the trade fair. The electric vehicle with radio remote control for ergonomic tool handling of loads up to 4,000 kg is a fully integrated transport solution.

It combines a powerful travel drive with an electro-hydraulic lifting platform, an integrated push-pull system, hydraulic ball bars and docking devices. This enables safe transportation, effortless automatic extension and retraction and precise positioning of heavy tools. A radio remote control and modular equipment ensure ergonomic handling and high flexibility.

Extended quick-release system for high loads

The Flexline-R quick-clamping system is based on the tried-and-tested Flexline models and has been optimized for high loads. It is particularly suitable for automated press lines with frequent die changes. The core element is a welded stainless steel pull-push chain, which offers high stability and durability. Reinforced brackets, stainless steel components and an emergency release on the motor increase operational safety. Precise sensor technology monitors the positions of the clamping element and optionally the end position of the chain.

Flexline R is available with two adjustment travels and with various hollow piston cylinders that offer up to 104 kilonewtons of clamping force. The compact design, low weight and use of low-maintenance modules make installation and servicing easier and reduce downtime. Thanks to the integrated power and signal cables, there is no need for a separate guide. The Green Edition is also available as a variant with 24 volt DC voltage, which is compatible worldwide and eliminates the need for retrofitting.

Complete solutions from clamping to changing technology

With these innovations, Roemheld is expanding its range of user-friendly, safe and efficient solutions for sheet metal forming. Visitors to the stand will receive a comprehensive overview of modern set-up time optimization – from clamping and transport to tool changes.

Web:

Hall 8, Stand 8505

www.roemheld.de