The quality of the finishing of weld seams is crucial to ensure the functionality, durability, safety and appearance of welded metal parts. Weak points such as spatter, burrs or sharp edges can be removed before they can lead to stress cracks or breakage.

Especially in the food and beverage industry, a professionally smooth seam on stainless steel or aluminum is crucial to prevent corrosion caused by moisture and dirt ingress. In the automotive, aviation and construction industries, appearance also plays an important role. Smooth, evenly polished surfaces are not only aesthetically pleasing, but also testify to high processing quality. It is also important for surface coatings, such as painting, electroplating or powder coating, that weld seams are smooth and clean to prevent premature flaking due to unevenness or contamination.

Stainless steel is often used for high-performance applications such as medical furniture, aviation equipment and commercial kitchens due to its durability, corrosion and heat resistance. The chemical, medical and food and beverage industries require bright and fine surfaces, as these signal or guarantee visual cleanliness and hygiene standards. Weld seam processing is therefore a critical process that ensures that the surface quality meets the high requirements. The problem with weld seams lies in the need to make them smooth and homogeneous, not only to avoid structural weaknesses, but also to meet aesthetic and hygiene standards. Defects such as pores, cracks or uneven surfaces can impair the function of the welded joint and must therefore be carefully processed.

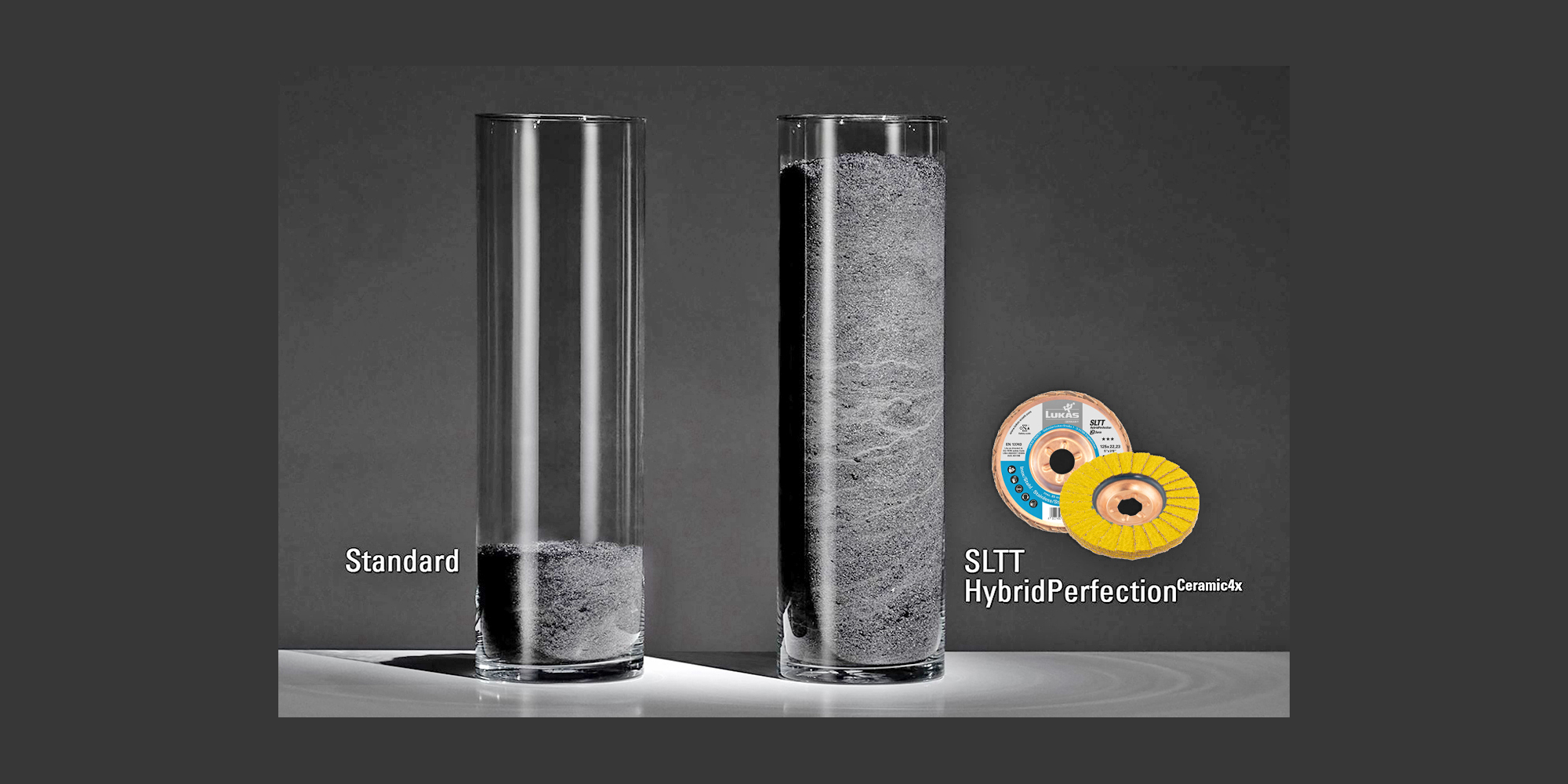

Specialized tools are essential for all types of weld seam processing in order to ensure high quality joints. LUKAS-ERZETT offers a wide range of tools developed for the rough and fine machining of weld seams. These tools are designed to work efficiently. One example of this is the LUKAS SLTT abrasive flap disc, which enables particularly high stock removal rates thanks to its patented sickle flap shape and state-of-the-art abrasive cloth. These sanding discs are ideal for chamfering edges, grinding out weld seams and removing surface irregularities. Chamfering creates space for weld seams and facilitates subsequent welding, while grinding out ensures an even seam surface.

With the U-Edge Pro, LUKAS has once again demonstrated its innovative strength: The U-Edge Pro is more than just a sanding tool – it is an innovation in sanding technology and is suitable for the highest demands. Its unique design enables effective sanding performance that surpasses conventional tools. Perfect precision for fillet welds: Fillet weld processing requires maximum precision and efficiency. Its unique design enables fillet welds to be processed with pinpoint accuracy, both on small surfaces and in hard-to-reach areas. Thanks to its U-shaped edge, the U-Edge Pro adapts effortlessly to large and small radii and the contours of weld seams.

It delivers precise, accurate and reliable results, even on the smallest corners and edges – more ergonomic, more effective and cleaner than with any other grinding wheel! The U-Edge Pro offers a wide range of application options for weld seam processing. Whether for grinding over fillet welds, for grinding out repair welds or for cleaning, paint stripping and improving the appearance – the U-Edge Pro is the ideal all-rounder tool for precise and efficient results in weld seam processing thanks to its radial grinding surface on the wheel.

LUKAS also has the right tool for the toughest and most enduring applications in weld seam processing: LUKAS V2 Power Heavy Duty abrasive flap discs. The V2 Power Heavy Duty is particularly robust even on the edge, on tempered steels, scale surfaces, titanium, stainless steel, hard coatings and armored weld seams. The innovative double combination of self-sharpening ceramic abrasive grain and multi-layer abrasive coating in a LUKAS-patented sickle flap shape enables a constant level of performance throughout the entire working life, just like the first use. This means that deburring, fettling, rust removal, smoothing or weld seam processing is always carried out with optimum sharpness – thanks to the self-sharpening effect of the ceramic grain: During use, ceramic particles that have become blunt break off again and again and expose new ones with fresh, sharp cutting edges, making tool changes considerably less frequent and reducing tool costs.

Stainless steel surfaces in the food and beverage industry must not only be clean and shiny, but also resistant to chemical cleaning agents and mechanical stress. LUKAS tools have been specially developed for requirements such as these and guarantee a flawless surface quality that meets the highest hygiene standards, as flawlessly smooth and hygienic surfaces are a must in industries such as the catering and medical technology sectors. Here, it is not only the structural strength of the weld seams that is important, but also the aesthetic appearance and compliance with strict hygiene standards. LUKAS offers special tools for this purpose, which enable surfaces to be finished to a mirror finish.

Precise tools are required for processing the weld seam to the surrounding surface through to polishing. The high-quality grinding and polishing tools from LUKAS can be used to create glossy or silk-matt surfaces that meet both visual and hygienic requirements.

The easy way to a perfect surface finish for medical and stainless steel kitchens, for example: With the P6PT polishing discs from LUKAS, you can quickly and easily achieve the desired polishing result from rust to mirror finish. A standard adjustable angle grinder is the perfect basic tool for working with these polishing discs. The lightweight, stable and flexible design of the P6PT polishing pad series enables outstanding surface results. Efficient processing of hard materials is effortless with this polishing disc series, as the hard and sharp abrasive grain of the four polishing discs – grit sizes P150, 240, 400 and 800 – ensures a long service life when cleaning, grinding or polishing. Thanks to cool grinding and the absence of flying sparks, these LUKAS polishing discs with silicon carbide are even approved for use in the aerospace industry. High break resistance, low vibration during work and easy handling make them ideal for manual use.

Particularly for industries with such demanding surface finishes, it is important to pay the same attention and care to hard-to-reach areas. LUKAS also offers an optimized tool for this: The super-flexible abrasive flap disc SLTs-flex Ø 125 mm zirconia alumina grain 60 flat with sickle-shaped flaps is the perfect alternative to roughing discs or conventional abrasive flap discs for processing hard-to-reach areas. It is ideal for deburring, fettling, rust removal, smoothing and weld seam processing. With an even larger flap projection than the SLT-flex, thanks to the small resin core with practical M14 thread, this abrasive disc offers maximum flexibility, adapts to uneven surfaces and requires little effort when working. In contrast to rough grinding, the shape and arrangement of the flaps patented by LUKAS also enables 50% less noise, less vibration, faster work, more power and better surface results.

Products from LUKAS-ERZETT stand for pioneering innovations in the tool industry. As a technologically leading manufacturer of system solutions for milling, grinding, polishing and cutting, the experts at LUKAS-ERZETT GmbH & Co. KG work continuously to develop products of the highest quality, performance and reliability. With their wide range of applications and impressive performance, they set standards in sanding technology and offer professional solutions for all sanding tasks, from rough work to the perfect finish.