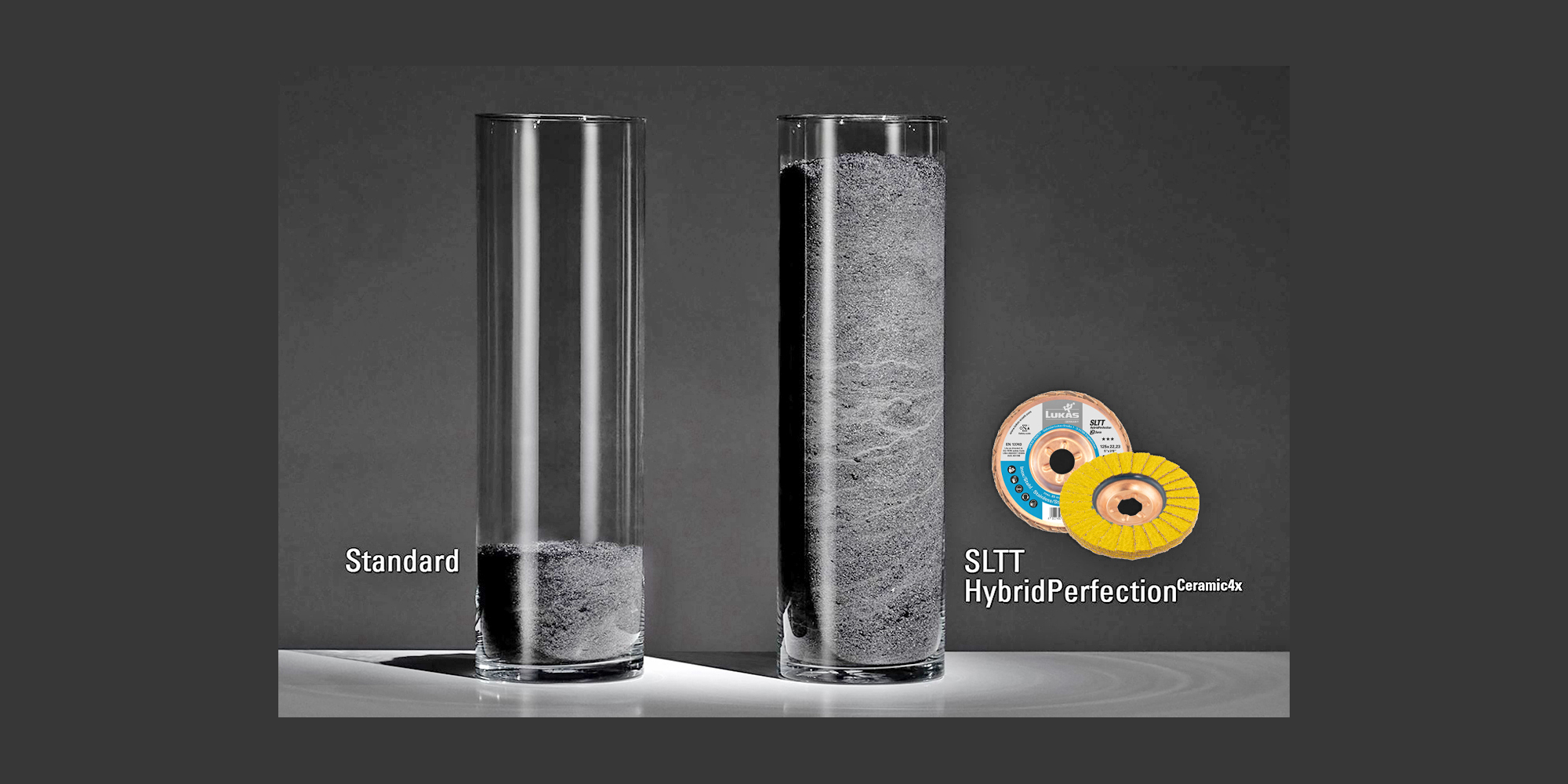

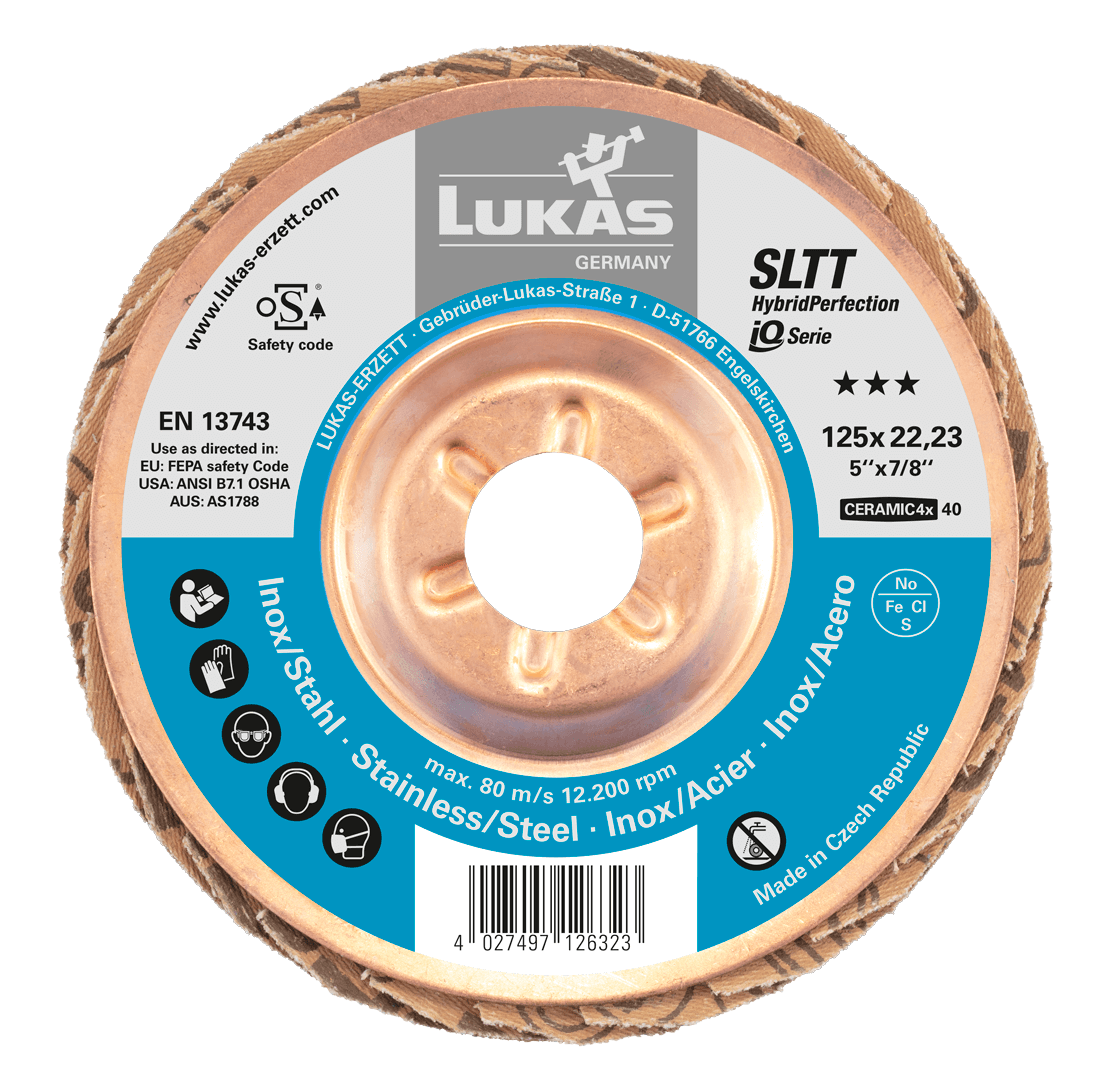

“Impressive results when grinding steel” is what Lukas-Erzett promises those who use the “HybridPerfection Ceramic4x” flap disc, as it is said to be capable of removing up to 8 kg of steel.

Eight kilograms of steel per disc – that’s quite a word. But the real advantage, according to Lukas-Erzett, lies not only in the high material removal rate, but above all in the cost-benefit ratio – which in turn is related to the low wheel consumption.

© Lukas-Erzett

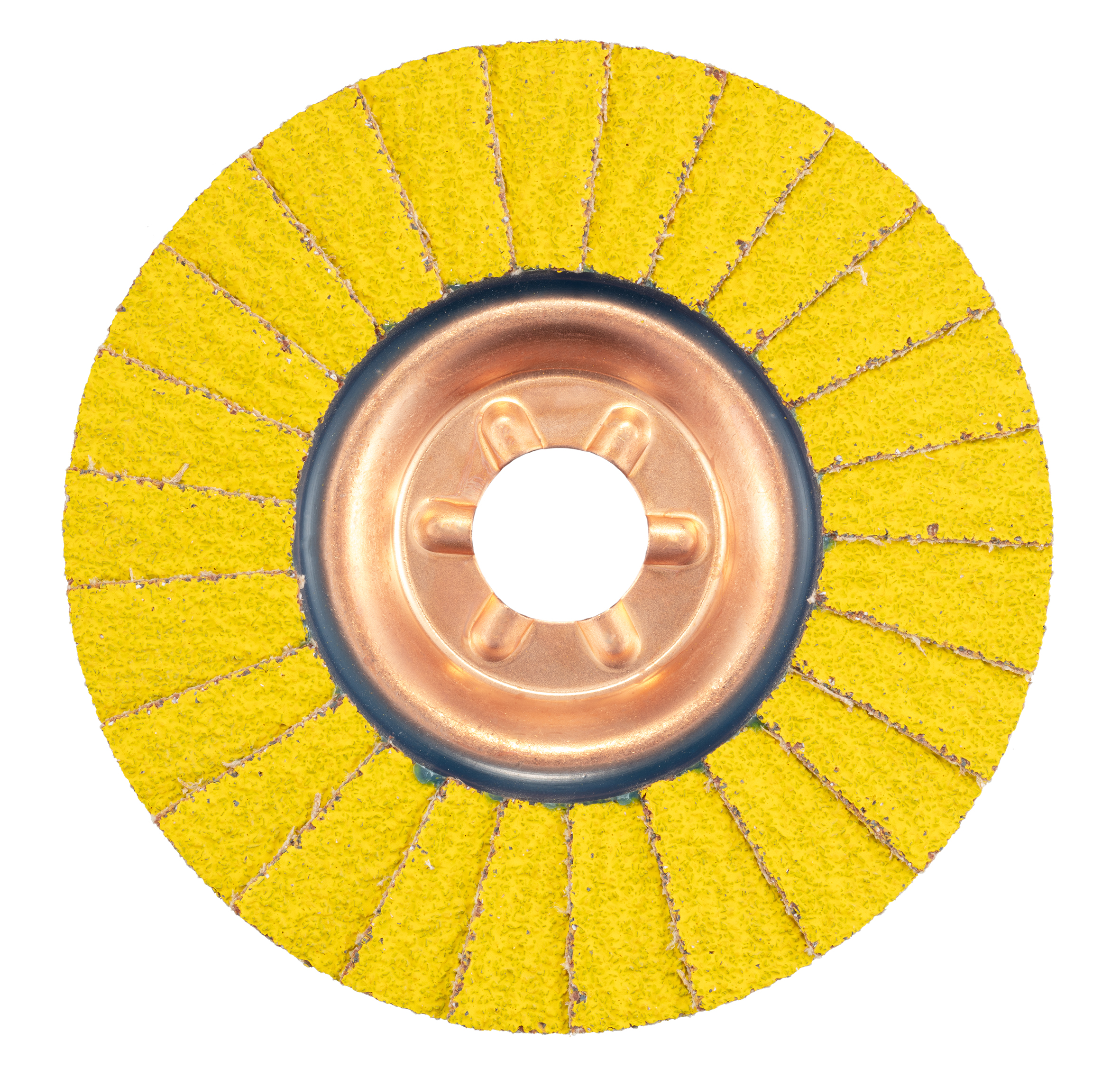

When grinding with hand tools, both the abrasive and the worker are crucial to success. The HybridPerfection Ceramic4x abrasive flap disc from Lukas makes work “much more ergonomic and efficient,” the supplier adds. The optimal balance angle of the tool allows the worker to achieve more power and stock removal with the same amount of force. Joints and muscles are less stressed, resulting in faster recovery between grinding sections. In addition, the HybridPerfection Ceramic4x is said to be up to 50 percent quieter than conventional grinding wheels, which significantly increases the quality of work.

In addition to the ergonomic benefits, the right abrasives also offer financial savings. One example is the steel work on the Hochmosel bridge – Europe’s largest bridge construction project in recent years. Over 1,700 meters long, 28 meters wide and a breathtaking 160 meters high, more than 32,000 tons of steel were processed. On conventional grinding wheels, it would take over 78,000 wheels to perform the required grinding work. Even a model with four kilograms of stock removal per disc would still require nearly 20,000 discs. However, the HybridPerfection Ceramic4x could save up to 68,700 discs, as it can remove 8 kg with just one disc. Only 9,825 HybridPerfection Ceramic4x panes would have been required for the entire construction project. This leads to significant cost savings.

Another example of the cost-benefit advantage of Lukas’ grinding solutions is shipbuilding. In shipyards, large amounts of metal are ground daily to achieve a smooth surface and precise fits. Conventional grinding wheels require frequent replacement and lead to longer working times. However, according to Lukas, the HybridPerfection Ceramic4x can save a tremendous amount of time and money. In addition, Lukas promises an immense time advantage for its grinding solutions, especially for large projects such as the Hochmosel Bridge. Fewer wheel changes save workers time, and machines can run longer and more consistently, which translates into lower repair costs in the long run.

However, the choice of the right abrasive influences not only the ergonomics and time savings, but also the quality of work and ultimately the costs. Low-quality abrasives can lead to out-of-round running, faster wear, lower material removal, higher noise levels and stronger vibrations. This increases the frequency of tool changes as well as the workload, which results in additional costs.

© Lukas-Erzett

Cost and time savings also play a decisive role in the construction of truck trailers and tankers, for example. In the production of vehicle parts, car bodies or wheels, high-quality grinding tools are essential to achieve an effective grinding process. With inferior abrasives, the work process would be slowed down, as several passes would be required to achieve the desired result. However, according to the manufacturer, the HybridPerfection Ceramic4x enables faster and more efficient machining, which would save labor time and costs. Especially for extensive steel grinding work, users benefit from this cost advantage and can offer their customers high-quality work in less time.

It is obvious that the choice of the right grinding tools has a significant impact on the cost-benefit balance. By optimizing worker comfort, reducing machine downtime and increasing productivity, Lukas-Erzett’s tools could help maximize the cost-benefit advantage in various industries.

The company, based in the Cologne area in the Oberbergischer Kreis, sees itself as “one of the technologically leading manufacturers of system solutions for milling, grinding, polishing and cutting”, specializing in the manufacture of, trade in and consulting on grinding, milling, polishing and cutting tools, drive machines with an extensive range of accessories.

Web:

lukas-erzett.com