The HS-Schoch Group offers an extensive portfolio: Stainless steel accessories for trucks, accumulation box systems, attachments such as excavator buckets or grabs and much more. With more than 400 employees at six locations and over 30 years of experience, the company serves customers from a wide range of industries, including construction, energy, transport & logistics and automotive. Modern machinery as well as short production and delivery times characterize the HS-Schoch Group. The investment in a MasterCut plasma cutting system from MicroStep was a necessary step for this.

© MicroStep Europe

It all started in 1986 with excavator buckets and grabs – it was the beginning of a dynamic growth. Today, the family business HS-Schoch is an expert on different terrains. The group is broadly positioned: from construction machinery accessories and wear parts to truck accessories/truck styling, steel construction, sheet metal processing and KTL and powder coating. The specialist for steel machining and processing offers solutions for a wide range of customers – from micro-enterprises to major corporations, from construction companies to construction machinery manufacturers.

HS-Schoch means “Made in Germany

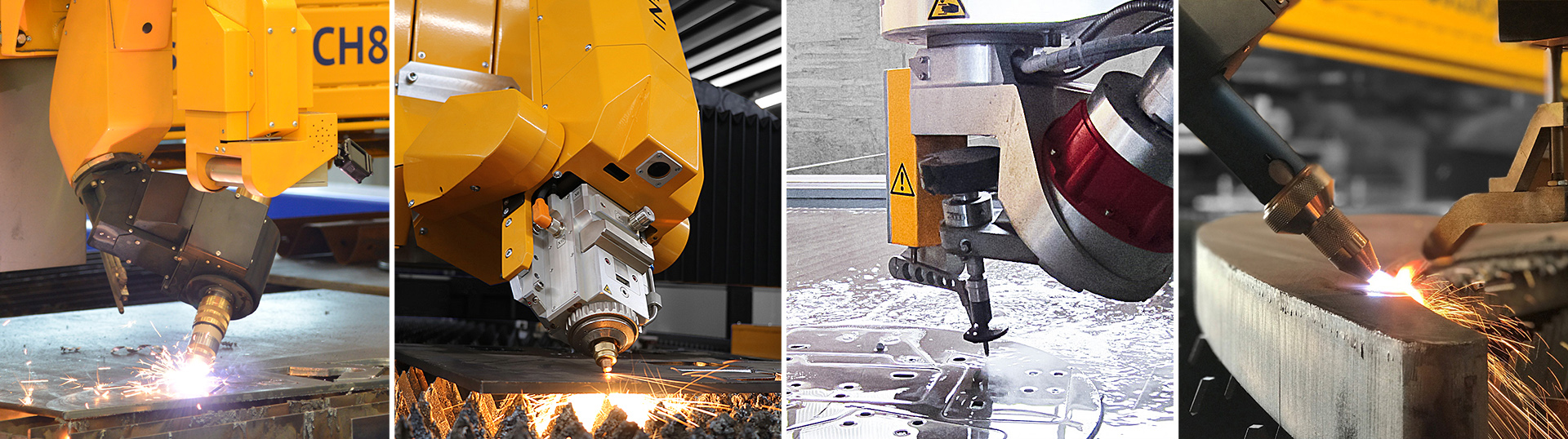

HS-Schoch serves a fully comprehensive production cycle: Starting with development and design, through sheet metal processing and surface coating, to assembly and logistics. All work steps such as flame cutting, all rolling work, bending, turning, machining, welding and painting are carried out “in-house” by experienced employees. To ensure consistent outstanding quality “Made in Germany”, HS-Schoch uses modern CNC machining centers. On the cutting lines, the company manufactures individual constructions to measure at short production and delivery times. In order to be able to continue to guarantee this to its customers, the company invested in the cutting area in January 2022.

© MicroStep Europe

Better performance thanks to new MasterCut

The new CNC cutting system replaced an aging machine. The HS-Schoch Group did not make the selection easy. After various consultations, they decided on a MasterCut series cutting system with a work area of 6,000 x 2,500 mm. “The overall package of performance, innovation and service convinced us. With its very good performance, the 2D plasma and oxyfuel cutting system meets all our requirements!” emphasizes managing partner Marcel Schoch.

With the new machine, the company can optimally cut different materials in the required thicknesses from 3 to 120 mm – including wear-resistant Hardox steels from individual to small and medium series production. “We can unconditionally recommend the implementation and the cooperation with MicroStep,” Marcel Schoch concludes.

Web:

www.microstep.com