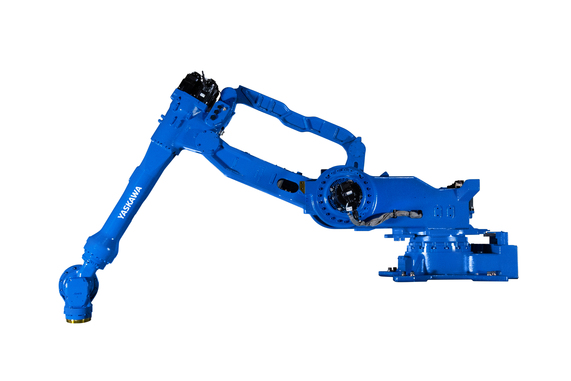

With the Motoman GP-Shelftype series, Yaskawa underpins its claim to offer a full range of robot models for every application. The range now includes five robot models with extended downward reach, for example for elevated positioning on steel frames or consoles. This allows workpieces to be removed from above and creates floor space underneath the robot for fixtures, tool changes and part transfers.

In addition to the classic console robots Motoman GP165R and GP200R, which are often used in the automotive industry (car body construction or press chains), Yaskawa offers special models with an exceptionally high maximum reach of 4 meters (GP120RL) or with particularly high payloads of up to 400 kg (GP300R, GP400R). Despite these impressive key figures, the robots have a slim design and a low dead weight.

© Yaskawa

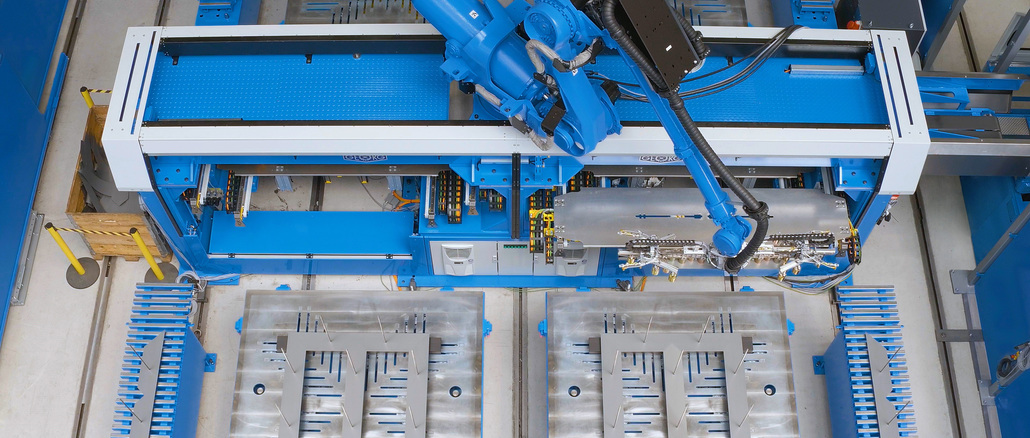

This robot series is designed for console mounting, which means that the manipulators can reach very far below themselves and work below their installation level. The already large operating range of these Motoman robots can, of course, be expanded enormously by means of travel paths or swivels, for example for interlinked multi-machine loading systems over large areas. The valuable installation space below the robot remains free for large machines (e.g. CNC machining and cutting machines, injection moulding machines), tools or conveyor systems that cannot be recessed into the floor.

The robots of the Shelftype series, like all Yaskawa robots of the universal GP series, are controlled by the compact high-performance MOTOMAN YRC1000 controller. This provides a variety of important functions for integration, communication or functional safety monitoring. Another very interesting feature is the possibility of programming the robots directly and seamlessly via integrated PLC function blocks – in the familiar PLC programming environment, so that a robot programmer is no longer required. The first users are already using robots from the new Shelftype series. For example, the machine builder and process optimizer Heinrich Georg GmbH, headquartered in Kreuztal in the northern Siegerland region, successfully uses it in its production facilities for stacking large sheet metal components for transformer core production.

About Yaskawa

With annual sales of 480 billion yen (approximately 3.8 billion euros), Yaskawa is a global technology supplier in the fields of robotics, drive and control technology, and solutions in the energy sector. Founded in Japan in 1915, Yaskawa has remained true to the principle of providing the highest quality products for over 100 years, earning it a world-leading position. In the process, Yaskawa has evolved from a motor manufacturer first to an automation provider and finally to a solution provider via the Industry 4.0 concept i3-Mechatronics.

Web:

www.yaskawa.de