Contract manufacturers are specialists.

This means they face very specific challenges, for example in terms of skilled workers and efficient production processes.

Nordspan GmbH, based in Schwentinental, Schleswig-Holstein, has recently begun to meet these challenges with the possibilities of digitalization.

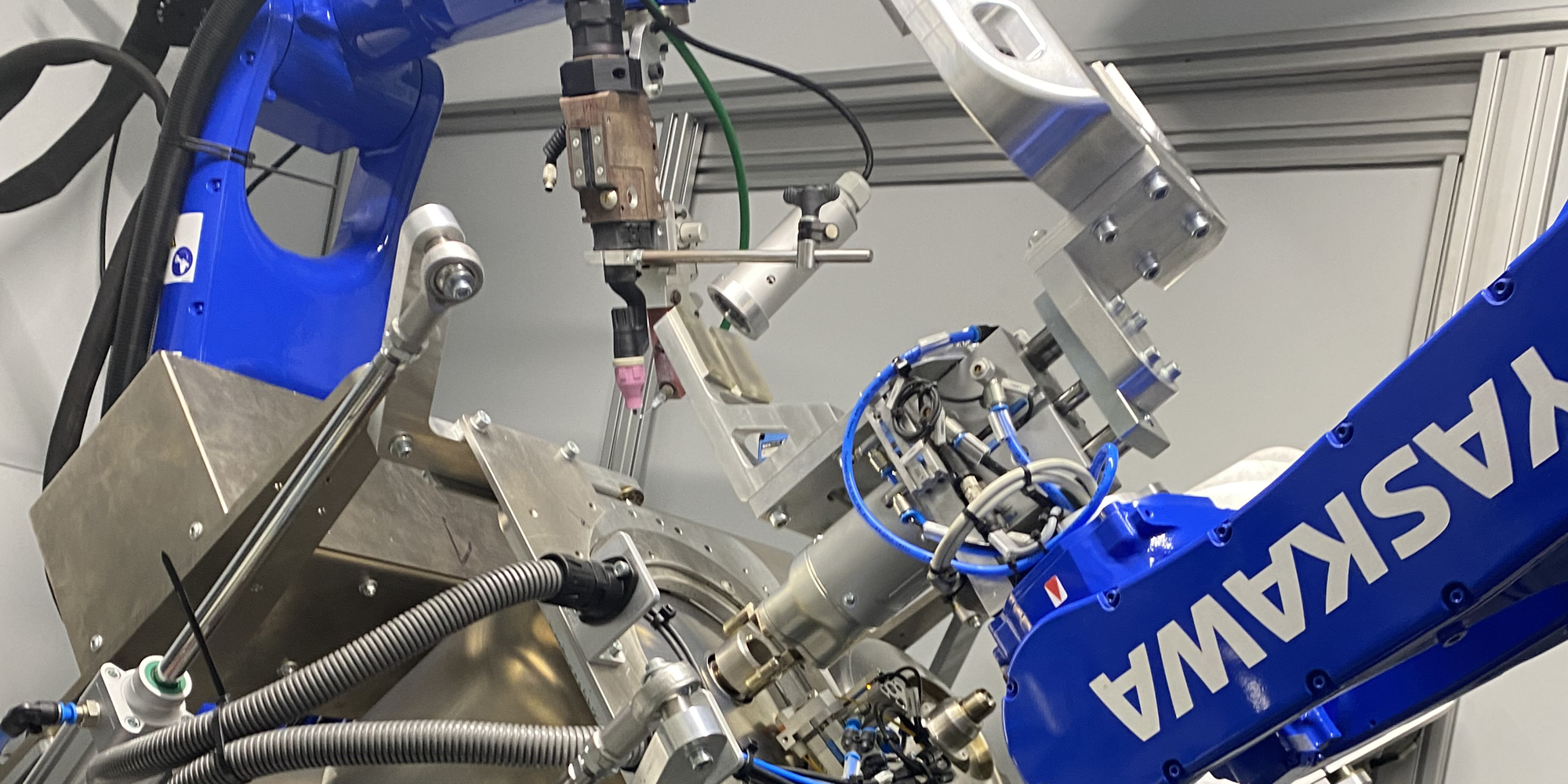

An automation solution from system integrator B-Automated with a Cobot HC10DTP from Yaskawa provides the basis for this.

There are at least two reasons why automation is now also a very attractive option for smaller production companies: firstly, skilled workers are now far too valuable to be used for monotonous or physically demanding tasks.

Secondly, robots are easier and more convenient to operate than ever before with the triumph of HRC-capable cobots.

Getting started with automation

Against this backdrop, those responsible at Nordspan GmbH in Schwentinental near Kiel were also looking for new approaches.

Founded in 2019 and employing around 30 people, the company is a contract manufacturer for its parent company JBS Systems and a leading manufacturer of flexible guide bushes and collets for automatic lathes.

“Unfortunately, we can hardly find any qualified employees, which is why automation and digitalization are vital for us,” says Managing Director Maik Jeß decisively.

A wire EDM machine was chosen for the first automation project.

In wire EDM, the collets are precisely slotted, which takes up to an hour per operation.

The automation of the process is correspondingly complex: the collets are machined under water.

This requires a clamping device that has no difficulty with the heavy soiling in the water caused by the process.

In addition, the finished, slotted collets must be thoroughly cleaned and dried immediately after removal from the machine bed in order to prevent the surfaces from tarnishing.

The system should also be easy to operate and flexible and be able to fit into the confined working environment.

© B-Automated Luciano Baumgart

Complete solution from the system integrator

In its search for the optimum concept for this challenging task, Nordspan found what it was looking for at system integrator B-Automated and its owner Luciano Baumgart, following a recommendation from Yaskawa.

The overall solution combines a ZeroCob modular system and clamping devices from ZeroClamp with a Cobot HC10DTP and a gripper from the Zimmer Group.

The interface between the robot controller and the eroding machine is implemented via factory software from the German provider Software4production GmbH (S4P for short).

This also lays the foundation for further digitalization and automation in the direction of autonomous production.

With the help of a web-based application, the system network can now be monitored remotely to enable further optimization and maintain a high level of system availability in 24/7 operation.

The heart of the cell is the cobot from Yaskawa’s HC (“Human Collaborative”) series.

Although it is a fully-fledged industrial robot, it can also work at a safely reduced speed.

In the event of any collisions, which are definitely not dangerous, the manipulator stops immediately so that people can be directly in its working area.

At Nordspan, the robot is also protected by an area safety scanner.

The selected cobot model offers a payload of 10 kg in combination with an effective reach of 1200 mm and impresses with its dust and waterproof IP67 protection class.

The Zimmer gripper is matched to the manipulator.

Specifically, it is a parallel gripper with spring return specially configured for the application.

This ensures that the component does not fall out of the gripper even if pressure is lost.

Like all models in the Motoman HC series, the HC10DTP is characterized by its particularly user-friendly operation: In addition to the use of a clearly laid out manual control unit, it is also possible to guide and program the robot arm directly by hand (Direct Teach, DT).

This saves time when creating robot programs.

© B-Automated Luciano Baumgart

Amortization in less than a year

In total, the complete construction, assembly and integration of the robot, including the peripherals with mechanics, electrics and software, took less than five working days.

And the system has since proved its worth, as Christian Wiese, machine operator at Nordspan, confirms: “The robot is very easy to operate and relieves me of the monotonous work on the eroding machine. Now I can finally take care of more important things and the robot colleague produces independently 24/7. What more could you want?” says the practitioner.

Thanks to the new automation, the wire-cutting machine can now also be operated autonomously in ghost shifts and thus achieves a completely unmanned autonomy time of almost 24 hours.

If a malfunction does occur, this is visible to the employees at all times thanks to the intuitive user interface and countermeasures can be taken to avoid wasting valuable machine time.

Nordspan Managing Director Maik Jeß is correspondingly satisfied: “The robot cell will have paid for itself in less than a year and machine utilization has already more than doubled. That’s how it should be!”

Web: www.yaskawa.de Euroblech Hall 26, Stand D56