After years of storming the summit, the laser is now the “smartphone among industrial tools”. Smartphones like lasers are technical marvels, but hardly anyone marvels at them anymore because they are too commonplace, too normal. But there is a lot of movement in laser technology right now: Laser users are learning to think differently. Athanassios Kaliudis from Trumpf shows the most exciting future topics and industries in laser technology.

Future field: Optics and beam guidance

What a sense of achievement it was a few years ago when ultra-short laser pulses drilled the finest of holes in rapid succession. And soon? Soon we’ll be able to drill a thousand holes at once.

This huge leap in production is preceded by a fundamental rethink. Previously, a laser beam was referred to as a laser beam that hits the material in focus, but the experts now specify: a laser wave acts in the material and the focus is distributed in space. The new way of thinking is called wave optics. The hitherto prevailing beam optics describes laser light as a beam, whereas the far more complex wave optics conceives laser light as a wave.

This is not a theoretical gimmick, but is driven by the requirements that certain materials and concrete applications have for laser light: Glass, for example, can be intrinsically modified by laser – watch out for the tech wording – and thus divided (this no longer has anything to do with cutting).

Thanks to wave optics, it is possible to split laser beams into thousands of parts. Result: processes a thousand times faster. So in the future, it will be a matter of shaping, bending, squeezing, pulling, chopping this coherent bundle of waves into bits and pieces, and getting it exactly where it needs to act everywhere at once. This places completely different demands on process development – and on optics.

Loosely speaking, and please don’t take it personally: Focusing is for beginners, the next ten years will be about diffraction. The model formations are highly complex and a mathematical Herculean task. But when the systems are up and running, laser processors will be delighted with fantastic productivity gains and unimagined fields of application.

Future field: sensor technology and process control

The first five-axis laser welding system was the pinnacle of precision engineering: it held a component under an optical system with micrometer and angular precision, which then fired blindly and deafly into space. And soon? Soon we place component X in the system, sensors on the optics detect the type of component, material, position and welding spots and weld exactly where it should be.

The whole crazy effort of high-precision clamping is dramatically simplified if the machine can orientate itself. This puts machine concepts from head to toe. Sensors are the logical answer to the questions that industry is currently asking itself: How do I deal with higher demands on quality and accuracy? How do I check results? How do I obtain data for simulations or artificial intelligence? How do I increase the degree of automation and thus productivity?

Ergo: Give the machines senses! They need to be able to perceive and interpret the world around them. So in the future, when you feed a component into a laser machine, it will automatically recognize what it has to do thanks to a multitude of sensors and start working right away. With laser marking, this fantasy will probably soon be a reality. All other laser applications will follow suit in the coming years.

Future field: digitalization and artificial intelligence

Networked manufacturing has got off to a good start in recent years, but the expansion of factory and production halls into smart factories is far from over. This can be seen, for example, in the areas of remote maintenance and external condition monitoring.

It’s all about availability and uptime. Of course, every user wants his laser system to always deliver reliably. However, since the semiconductor industry and consumer electronics are fully committed to lasers, things are changing. Both industries have almost absurd requirements for the availability of their systems and push the entire laser technology with their expectations. This is good for all industries.

Meanwhile, artificial intelligence (AI) is moving into the factory halls. While AI has so far been able to play to its strengths in intangible processes such as production planning, it is now moving closer to the machine. In the next few years, electron brains – fed with data from sensors and simulations – will design completely new laser processing strategies, refine the process steps as they learn, and ultimately take over the programming of networked machines themselves. The productivity gains will be huge.

Future field: New beam sources

The basic concepts for beam sources have all been known since the 1970s: CO2, solid state, diode, fiber. But they are far from being fully developed. Engineers are always finding new tricks to get more out of laser systems: higher pulse energy, higher average power, shorter pulses, better beam quality. This will continue in the coming years.

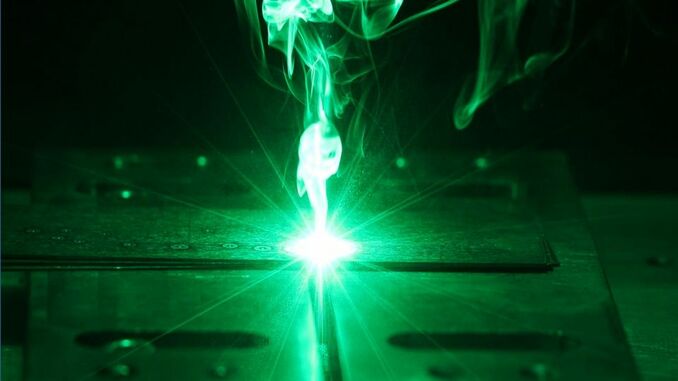

But beyond the race to set the latest industrial laser record, what are the deeper developments that users should be keeping an eye on? First, the spectral range becomes larger. Laser light in all possible wavelengths is already available in principle, the only problem is usually the necessary power. This obstacle is gradually disappearing in all wavebands: thanks to the reliability of the disk laser, laser light can be generated in all possible colors in a powerful and industrial way. A current example is green laser light, which is excellently absorbed by non-ferrous metals and is a boon for applications in electromobility. For all conceivable applications, it will soon be possible to produce powerful beam sources with exactly the right wavelength.

Second, lasers are getting smaller. Semiconductor lasers, diode direct lasers and others are shrinking to miniature size. This simplifies their use in all kinds of systems – from mobile phones to operating theatres – and enables entirely new applications such as laser-based scanning of the environment in autonomous driving or in quality control. The first developers are already working on simply packing the laser medium into a light guide: laser light is thus created virtually on the move. Such beam sources are not fundamentally new, but it is becoming apparent that the old concepts are displaying a flexibility that hardly anyone would have believed them capable of in the meantime.

Future field: electromobility

The transformation of the automotive industry from combustion engines to electromobility brings with it new applications – and it is of course the laser that enables the highly efficient series production of the new components.

First, the battery. What is often referred to as a “battery” is actually a complex structure consisting of a battery cell, a battery module and a battery pack. Batteries for electric cars consist of several layers of extremely thin copper and aluminum foils, which are cut and welded together by the laser. Liquid electrolyte is then poured in and the battery is welded with a lid – these welds must be absolutely tight to minimise the risk of fire and injury.

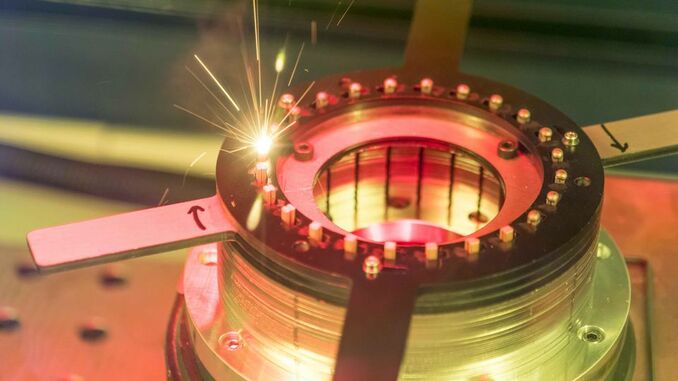

Second, the electric motor. Here, manufacturers are increasingly relying on so-called hairpin technology. Usually, the stators in electric motors are given a winding of copper wire. This “coil principle” creates a magnetic field that makes the electric motor run. Like a knitting needle, every single groove of the stator is wrapped around – in and out, in and out. This is too costly and time-consuming for powerful electric motors that have to drive a car, due to the thick copper wires. That’s why the industry relies on hairpins. Here a compressed air gun shoots a rectangular copper wire, similar to a hairpin, into the groove. The wires are then twisted into each other and welded by laser – this also creates a coil.

And thirdly, high-performance electronics. With charging plugs, current transformers and rectifiers, a whole range of new power electronics is coming to the car. While a 12- or 24-volt battery is sufficient for all the electronics in a combustion engine, voltages of 800 volts quickly accumulate in an electric car. This means that extremely robust connections are required. As an excellent conductor of heat and electricity, copper is the material of choice here. However, copper can only be welded efficiently with a very special laser, otherwise too many spatters occur and the risk of short circuits increases: the green laser (see also section on the new beam sources).

Future field: quantum technology

Quanta are everywhere, but they behave quite strangely for our human understanding. For example, they may have two mutually exclusive states at the same time or be in two different places at the same time. This is more than confusing, but it does open up exciting possibilities.

Quanta carry certain information, for example their spin, i.e. their intrinsic angular momentum. In order to be able to read out this information and use it for computing, for example, we have to make it visible, i.e. amplify it to a certain extent. This succeeds with quanta of light, i.e. photons. But not with just any photons.

Depending on the measurement task, it is crucial that these photons have certain properties, for example a very precisely defined wavelength or polarization. To do this, you need a beam source that does exactly that: generates photons with a precisely defined wavelength and with a very specific polarization.

The Trumpf subsidiary Q.ANT develops and produces solutions for industry with such beam sources. Their field of application is “infinite”. Quantum technology will be there when it comes to new types of sensors for medicine and autonomous driving, new types of data encryption, new microscopes and apparatuses that we can’t even imagine today.

Web:

www.trumpf.com