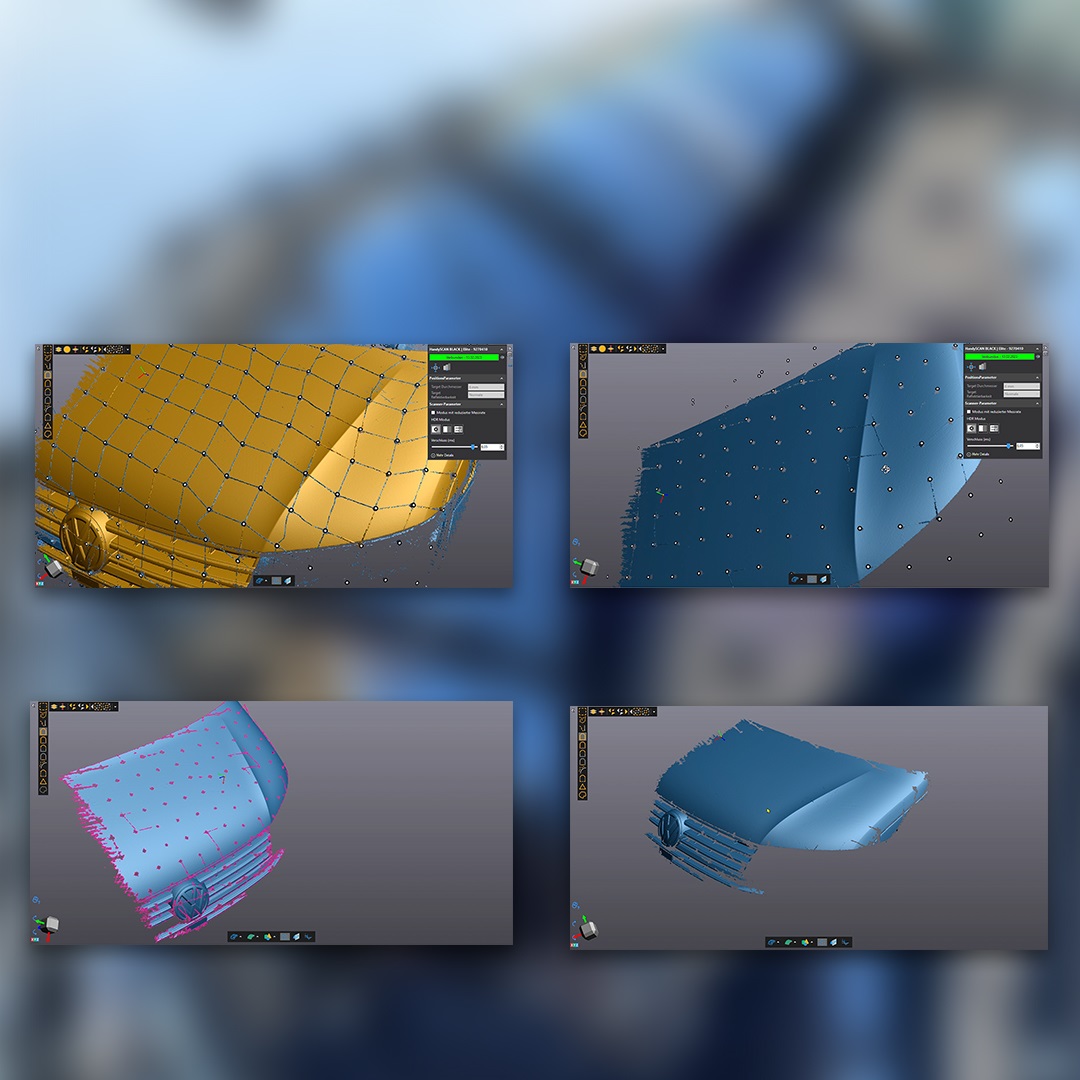

Measurement or so-called reference points are often placed on the component surface to be scanned before the 3D scan. The points are used to combine the individual scan images into an overall scan of the complete component and are thus often essential for accurate scan data.

With a network of reference points, scanning large components, such as engine hoods or entire vehicles, is now even faster and easier. The Aesub target net is placed over the object to be scanned – and it is already provided with reference points covering the entire area. The 3D scan can start immediately. The target net is thus an efficient alternative to the adhesive dots used in the past, which had to be glued on individually and then laboriously removed again after the measurement.

© Aesub

300 reference points

The reference points are distributed at regular intervals of 100 millimeters on the 1500 x 2500 millimeter mesh. In total, the network of this size has about 300 reference points. Due to the high density of reference points, multiple scans from different perspectives can be performed very quickly.

Target net for metallic and non-metallic components

For metallic components, there are magnetic reference points that hold securely on the surface. For non-metallic parts, for example made of clay or plastic, the mesh is stretched or, depending on the material/surface, attached with optionally available suction cup holders. The reference points “float” about 10 millimeters above the surface. Depending on the scanner version, the black glossy mesh threads are not visible on the scan or can be removed with suitable software with just a few clicks, for example using an offset function.

Retro-reflective reference points

Currently, the target net is equipped with 6 mm retro-reflective reference points. In the future, there will also be a version with 3-mm dots. Nets with non-reflective dots can be made upon request.

Can be reused almost indefinitely

The Target Net is handy, quick to pack and easy to transport. Since it can be reused almost indefinitely, the need for consumables is significantly reduced. The time-consuming process of fixing and subsequently removing the reference points is also reduced to a minimum, thus saving a lot of time and costs.

Special sizes, for example 8,000 x 12,000 millimeters, can also be manufactured.

Aesub will present the Target-Net at Control 2023: Hall 3, Booth 3205

Web:

www.aesub.com