Blackbird’s OCT-based sensor technology provides real-time visibility and control across all phases of the remote laser welding process, significantly enhancing both process stability and flexibility.

Across the production of strip, sheet and tube components, welding processes have been facing steadily increasing demands for years. Higher cycle rates, more complex geometries, thinner materials and rising quality requirements are pushing conventional process windows and downstream inspection concepts to their limits—both in terms of quality and cost. This is precisely where Blackbird comes in, with a technology that, for the first time, fully integrates welding process control, geometry detection and quality assessment directly into the live process.

Blackbird operates as a technology provider for laser-based joining processes, taking an end-to-end approach that spans seam detection, adaptive process control and inline quality assessment.

Why Sensor Technology Is Becoming Indispensable

In modern welding processes, achieving high cycle rates is no longer the sole challenge; component variability and geometric deviations play an increasingly important role. In real-world production environments, joining edges rarely align exactly as designed. Gap widths vary, components deform during welding, and material properties fluctuate.

A laser beam with spot sizes of only a few hundred micrometers therefore encounters joining conditions with tolerances that are orders of magnitude larger. Reliable operation under these conditions is not possible. Improving component geometric accuracy is one—albeit costly—option. The alternative is sensor technology dynamically adapting the laser path and intensity to actual component geometries—and this is precisely what Blackbird’s OCT-based sensor technology delivers.

Remote Laser Welding as the Foundation for Speed and Precision

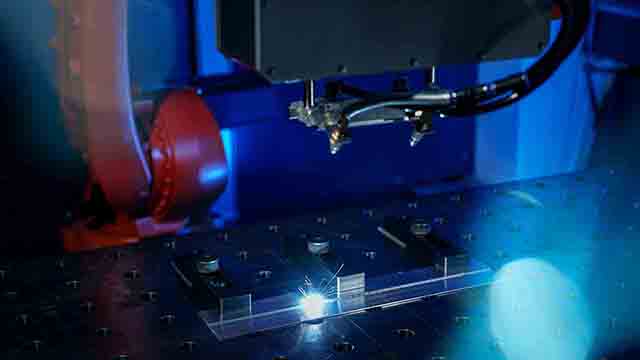

Blackbird’s technology is built on remote laser welding, in which the laser beam is directed onto the component from a greater working distance. Movable mirrors within the laser scanning system deflect the beam across the welding geometry with extremely high dynamics and precision. The result is very high processing speeds, short cycle times and, when required, near-maximum utilization of the laser source.

This technology demonstrates its strengths particularly when processing sheets, profiles and tube components with multiple short weld seams or complex contours. While conventional, contact-based processes require robots or tools to be mechanically positioned and moved, remote laser welding allows the laser beam to jump between individual seam segments within milliseconds. High speed, highly flexible beam paths and precision are inherent to the system.

OCT – Optical Coherence Tomography as a Key Technology

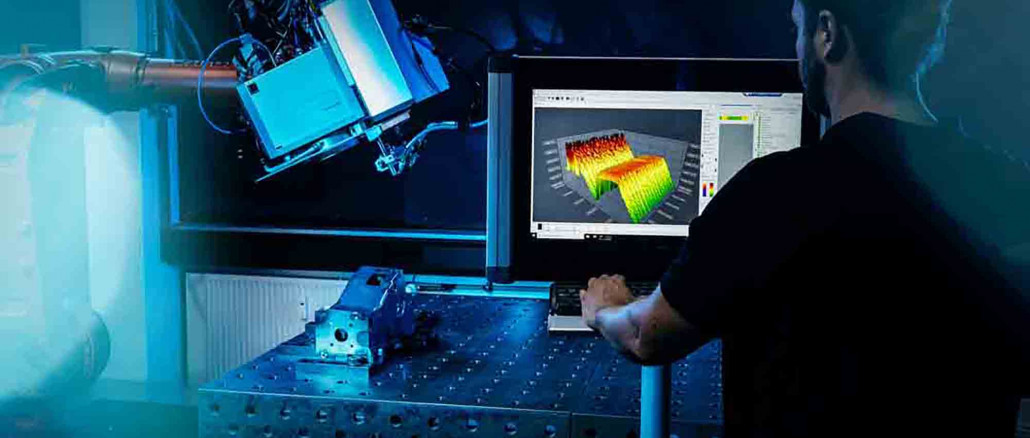

Despite the high process dynamics of remote laser welding, the OCT system developed by Blackbird provides real-time measuring, monitoring and closed-loop control across all phases of the process. Unlike conventional optical sensors that rely on indirect process signals, OCT actively emits light and operates as an absolute distance measurement technique. This allows surfaces to be scanned point by point or across an area—comparable to a highly precise optical ruler.

Within the welding process, OCT sensor technology performs three central tasks:

Seam detection prior to welding (pre-process):

The measuring beam travels ahead of the laser and analyzes the geometry as well as the actual position of edges, fillets or overlaps.

Monitoring of the melt pool and penetration depth (in-process):

The measuring beam penetrates directly into the keyhole—the region in which the laser melts the material and forms the vapor capillary—and determines, among other parameters, the penetration depth during the process.

Trailing seam evaluation (post-process):

Here, the measuring beam jumps behind the laser and analyzes seam geometry, excess weld material, pores or seam interruptions.

These three analysis modes alternate at such high speed that continuous data acquisition in near real time becomes possible. In addition, OCT is completely insensitive to process emissions, ambient light and laser reflections, delivering reproducible absolute measurement values even under real production conditions.

Real-Time Control Instead of Downstream Inspection

A key strength of the Blackbird solution lies in the real-time integration of sensor technology and process control. When the system detects, for example, a change in gap width within the weld seam area, laser power, beam position and beam modulation are adjusted within milliseconds. The welding process responds adaptively – comparable to an experienced manual welder, but with vastly higher speed and reproducibility.

In practical terms, this results in:

• wider tolerance windows for component deviations,

• reduced requirements for clamping and fixturing technology,

• lower scrap rates,

• more stable processes even with complex geometries.

Inline Quality Assessment

Quality assessment within the process is another critical aspect. The geometric data captured by OCT are evaluated in real time and consolidated into quality metrics. Depending on the application threshold values can be defined to classify a component as acceptable, requiring rework, or scrap.

As a result, separate downstream inspection stations are no longer required in many applications, along with additional robot cells, measurement systems and associated logistics, while quality results are available immediately after welding.

Closing a Critical Gap in Remote Laser Welding

BBlackbird is currently the only provider offering this combination of precision, measurement speed and control dynamics in conjunction with on-the-fly remote laser welding. This is no coincidence. The company is part of a group of high-tech providers whose sister companies—including SCANLAB, Lessmüller Lasertechnik and HOLO/OR—deliver advanced solutions in the laser and scanning systems field.

At Blackbird, hardware, sensor technology, control systems and software are therefore not autonomous components connected via standardized interfaces. Instead, all components are deeply integrated already during the design phase, enabling synchronization at the microsecond level. This deep integration allows dynamics and response times that cannot be achieved using conventional standardized components.

Rather than adding complexity for users, however, this level of deep integration offers a unified operating interface and short commissioning times.

A Foundation of Experience

This technology is built on decades of experience in laser material processing—from the early days of remote laser welding in automotive body manufacturing to today’s high-volume applications in sheet, profile and tube production, such as those required for battery cell and module manufacturing in electromobility. Blackbird does not position itself as a mere system supplier, but as a partner that develops and optimizes welding processes in close collaboration with the user.