The new energy storage modules from Eckelmann FCS are an add-on for more “green” drive technology in production machines and plants – application-optimized scalable for converters up to 250 kW, easy to handle and maintenance-free.

How can unused energy-saving potential in the DC link be leveraged? Eckelmann FCS now presents easily scalable energy storage solutions for this purpose. The new E°Darc DCB modules are available for capacitances from 8 to 160 mF and are designed for a continuous current of up to 300 Aeff. Inverters with a power of up to 250 kW are supported. The broad product range enables solutions that are precisely tailored to the application, and the completely ready-to-connect modules can also be easily integrated into existing machines. The memory modules can be operated in combination with commercially available converters with a three-phase mains connection and with DC link voltages of up to 900 VDC. Thanks to the data interface to common energy management systems, the benefits of the energy storage systems can be transparently analyzed and documented.

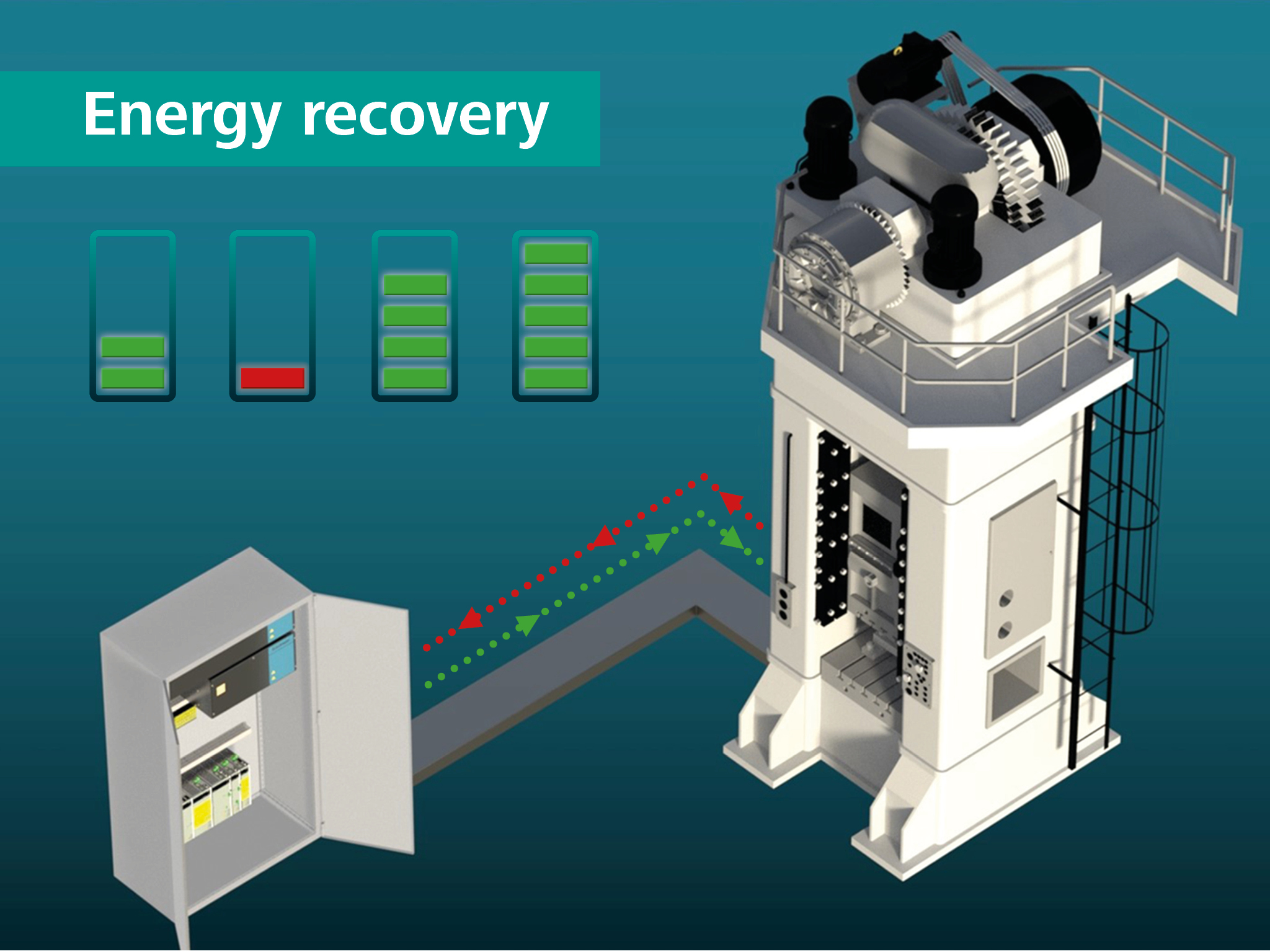

Energy recovery saves up to 40 percent energy

The energy storage systems avoid high peak loads (peak shaving), reduce energy costs by up to 40 percent – depending on the application – and thus reduce the CO2 footprint. The modules are completely ready for connection, finger-safe (IP 10B), UL-compliant and flexibly scalable for a wide range of applications in industry.

The capacitor-based DC link storage modules are used for short-term storage of electrical energy generated by regenerative drive controllers during braking of drives. The accumulators provide the drive system with the energy for the next acceleration process, so that considerably less energy from the grid feed is required for this. This effectively smoothes peak loads.

Energy storage as an ideal add-on for servo presses

The E°Darc DCB modules can be used, for example, to temporarily store the braking energy of large drives in production lines. As initial use cases, for example on servo presses in forming technology or short-cycle presses, demonstrate, the investment in energy storage quickly pays for itself. Here, the energy storage systems ensure a lower energy feed-in overall and a constant energy supply. Other applications include packaging machines, machining centers or generally dynamic reversing applications – in other words, anywhere there are constant braking and acceleration processes or machines with short cycle times.

Eckelmann FCS advises its customers on the optimal design of energy storage systems based on a precise energy analysis of the individual application. Even with existing machines, large unused savings potentials can often be leveraged with little effort.

Web:

www.eckelmann.de

Euroblech Hall 11, Booth E07