The production of pipes for aircraft is subject to stringent requirements, as even the smallest product defects can have fatal consequences. The company TDM, which was founded in Morocco, therefore relies on the experienced tube bending machine manufacturer Schwarze-Robitec. Its reliable, robust and precise machines produce tubes of various geometries for aircraft manufacturers. The modern production facility is regarded as a showcase project for the country, which is pursuing ambitious goals.

© TDM Aerospace

Tubes and Ducts Maroc Aerospace (TDM) was founded in Morocco in 2018. The company manufactures piping for the aerospace industry and acts as a Tier 1 supplier for well-known aircraft manufacturers. TDM currently employs 70 people and is based at Mohammed V Airport in Casablanca.

TDM is a flagship project as part of the North African state’s strategy to become an important global location for system and module suppliers in the aerospace sector in the coming years. To this end, the Moroccan Aerospace Investment Company (MAIC) invests in companies such as TDM and holds a majority stake.

Morocco wants to further expand its activities in the aviation sector in order to create local supply chains and make the country an important trading partner. Many free trade zones have been established. The kingdom specifically promotes companies in the aviation industry, for example by providing financial support for employee training and granting other privileges.

Looking for a competent partner with experience

The founders of TDM have more than 60 years of experience in the manufacture of tubes for the aviation industry. They were looking for a manufacturer of tube bending machines with many years of expertise in the aerospace industry for the demanding production of tubes for hydraulic lines as well as cooling water, waste water and brake lines in aircraft. “We needed a partner who could support us not only with high-quality technology, but also with expert advice,” says Jürgen Viehrig, CEO and co-founder of TDM. “Schwarze-Robitec has been working in this field for over 50 years and knows the special requirements in terms of surface quality, wall thickness and ovality down to the last detail.” This is because maximum precision is required when manufacturing pipes for the aviation industry. Tight tolerances must be adhered to and the pipes must be manufactured absolutely crease-free in a safe process.

Lean manufacturing in a modern factory

© TDM Aerospace

At TDM’s new production plant, the pipes are first cut to size, then bent and measured. This is followed by the grinding, polishing and joining of pipes with fittings in an orbital welding process. The pipes are checked using a digital X-ray machine, then subjected to a pressure test, cleaned and dried. This is followed by labeling, quality assurance, packaging and shipping.

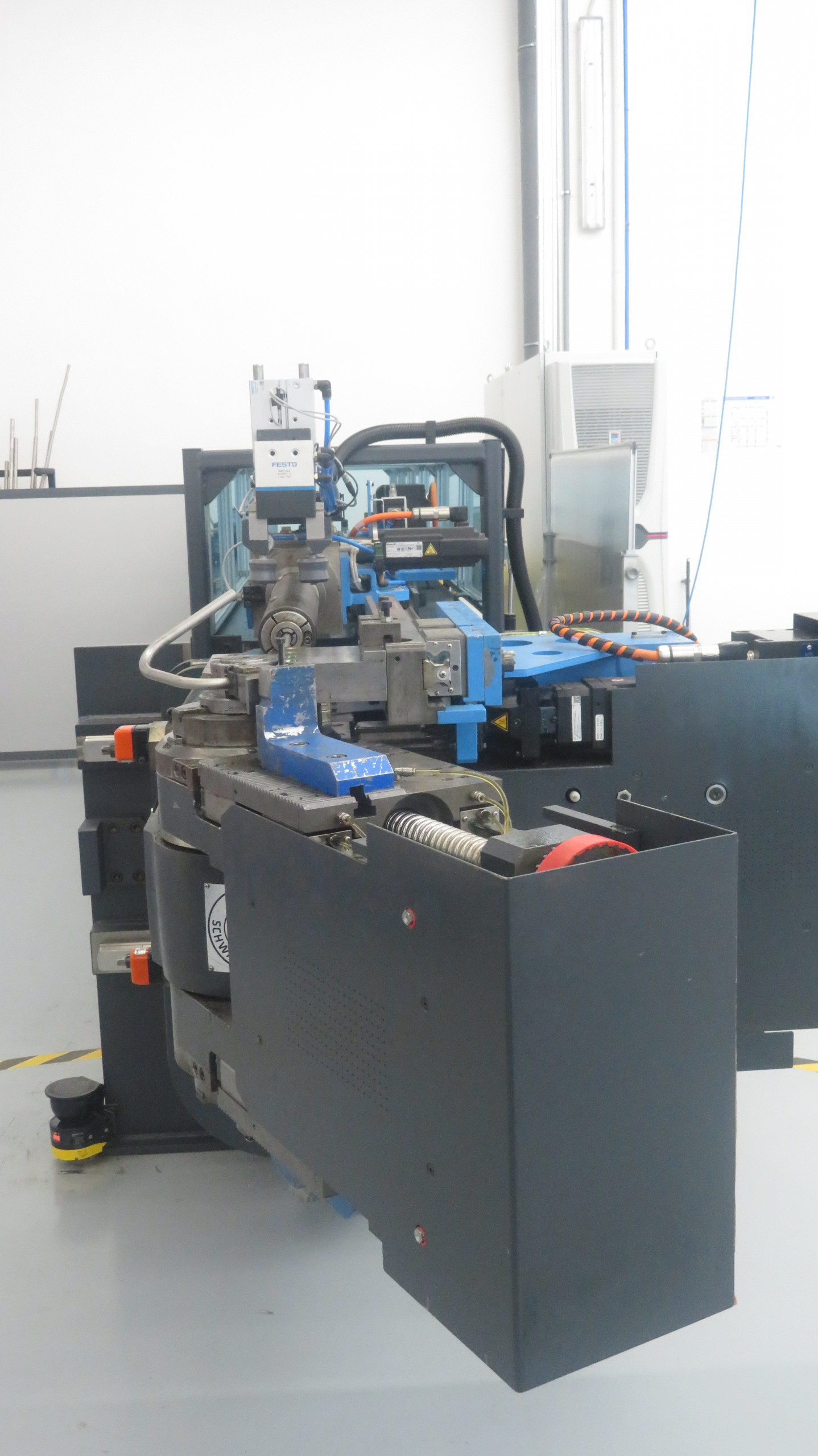

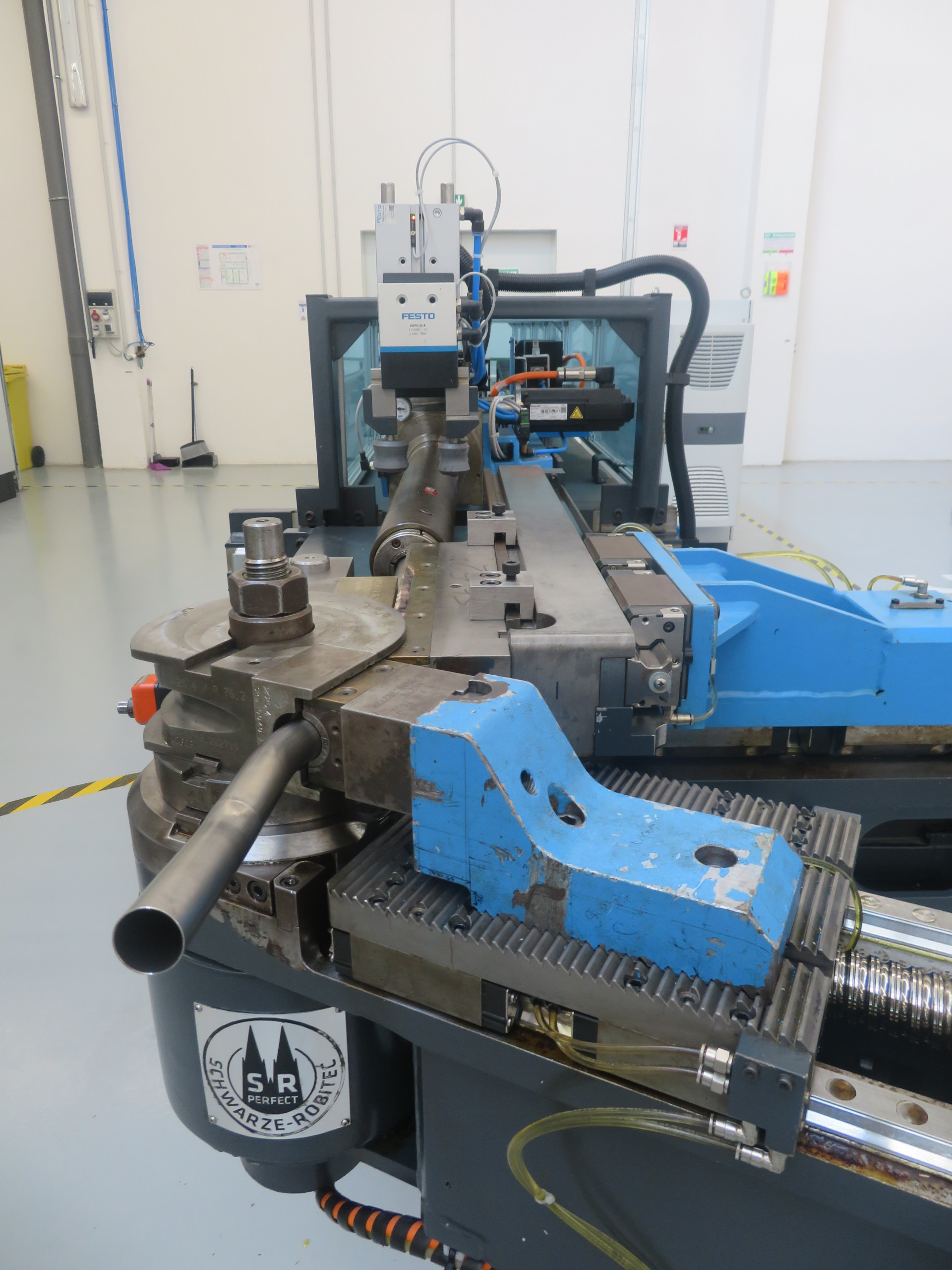

Two Aircraft Edition tube bending machines from Schwarze-Robitec are used for the bending process: the single-groove CNC 40 E TB and the CNC 40 Rotary with a rotating bending head. They bend titanium and stainless steel tubes with a diameter of 6.35 to 31.75 mm. “We have the capacity to produce 400,000 tubes a year,” says Jürgen Viehrig. “We are not focusing on the production of replacement or special parts, but on semi-automated and lean production in large series.”

The aircraft manufacturer placing the order produces several aircraft in a month, with around 600 different pipes required for a single aircraft. Each component is unique. In order to bundle its capacities, TDM manufactures in batch sizes 1 to 10, delivers the required quantity and stores the remaining components until the customer registers a new requirement.

For particularly complex geometries, TDM uses the CNC 40 Rotary with an exposed bending template. The option of flexibly moving the bending head to the left or right side is used for around 20 percent of components. Thanks to modern CNC technology, multi-dimensional pipe systems can be produced precisely and reliably without a weld seam in a single work step. For example, coiled tubes and pocket tubes are produced in the shape of an angular U. These tubes are often used in aircraft to compensate for expansion and vibrations.

Low wall thicknesses and demanding material

© TDM Aerospace

The demands on production are high. On the one hand, relatively large-diameter tubes with very thin walls are bent, and on the other hand, the material used is titanium, which has a high strength. The bending process must therefore be very slow and vibration-free at the same time.

Despite the thin wall thicknesses of 0.56 to 0.88 mm, no cracks or creases may occur during bending. “From a purely technical point of view, this is a major challenge,” says Philipp Knobloch, Global Sales Director New Machinery Equipment at Schwarze-Robitec. “A high torque is required to achieve a smooth movement. However, with slow movement, there is a risk of vibrations occurring, which can lead to wrinkling.”

Special devices such as pleat smoothers can be used to counteract this. Titanium is light, stable and corrosion-resistant, making it particularly important for aviation technology. However, the material is very brittle and can tear easily. Particular attention must also be paid to the surface finish. For example, the proportion of dents, scratches, creases and notches must not exceed 1 percent in depth, measured against the pipe diameter. In addition, an ovality of less than 3 percent is required, as the pipes must be almost perfectly round to ensure ideal flow properties.

The smallest product defects can have fatal consequences. For example, leaks in hydraulic pipes can mean that the landing gear does not extend and the aircraft cannot land. If fuel leaks from a pipe and drips onto a hot spot, the worst that can happen is a fire in the aircraft.

Certification as an additional requirement

© TDM Aerospace

Aircraft manufacturers place high demands on their Tier 1 suppliers in terms of quality and safety. This means that not only the components are checked in detail, but also the entire production process is validated. Accordingly, the pipe manufacturing process at TDM is also subject to strict regulations, compliance with which is checked and audited on site on behalf of the aircraft manufacturer. In this context, there are also special requirements for the tube bending machine manufacturer. “Thanks to its many years of experience in the aviation sector, Schwarze-Robitec knows the specifications precisely and can easily meet them,” explains Jürgen Viehrig. “In addition, the contact persons were and are always available to advise us and thus also provided valuable support for the entire certification process.”

In recent years, TDM has obtained numerous qualifications and also fulfills the DIN EN 9100 quality management system standard, which applies specifically to the aviation industry.

High accuracy, smooth surfaces and a robust process

Schwarze-Robitec ensures precise bending results with the two tube bending machines in its Aircraft Edition. “The accuracy can be increased even further through targeted control of the axes and is ± 0.05 mm,” explains Phillip Knobloch. “The result is 0.05° for twist angle and bending accuracy.”

The tube bending machines are designed for use under continuous and long-term stress. The robust design enables reliable operation without malfunctions or unnecessary process interruptions. This feature is particularly advantageous in countries with a weak infrastructure, where there is no close-knit network of specialist companies on standby in the event of faults. “The results speak for themselves: the ovality is less than 3 percent and the surfaces are excellent – absolutely wrinkle and scratch-free,” emphasizes the TDM founder. “Even with our most complicated pipe geometry with 16 bends, we achieve very precise results with low tolerances.”

Support beyond commissioning

Before TDM commissioned Schwarze-Robitec to supply the two tube bending machines in 2019, a preliminary acceptance test was carried out at the German machine manufacturer’s plant in Cologne. By processing ten selected components, the bending machine manufacturer ensured that all specifications were met and delivered flawless bending results.

TDM commissioned the Schwarze-Robitec bending machines in Casablanca at the beginning of 2020. A photometric measuring cell was also supplied, with which the pipe geometries, lengths between the bends, bending angles and other important parameters can be determined. Following the commissioning, the TDM employees received extensive on-site training.

This was followed several months later by follow-up training. “One of the biggest challenges was that we had to realize the production here on site without skilled workers,” emphasizes Jürgen Viehrig. “Training was therefore of central importance to us. In Schwarze-Robitec, we have found a reliable partner who actively supports us beyond delivery and commissioning.”

The supplier-customer relationship is open, honest, trusting and transparent. Schwarze-Robitec lives and breathes customer proximity, even over long distances. The experienced service team is on hand to identify and solve potential problems remotely or to carry out maintenance and repair work directly on site. The Tier 1 supplier intends to expand its capacities over the next few years and is therefore planning to install up to three more tube bending machines. TDM hopes to be able to continue working with the experienced specialist from Cologne.