Trumpf presented the new TruPunch 3000 punching machine and its TruMatic 3000 fiber punching laser extension at the virtual Euroblech 2020 (Digital Innovation Summit).

From the outside, the new machine looks almost exactly like its little sister, the TruPunch 1000. This is due to the fact that the DeltaDrive now also provides more throughput and a very compact design in the 3000 series. In addition, the developers at Trumpf have packed new functions into the machine to increase part quality and productivity. Simultaneously with the market launch of the TruPunch 3000, the new punch laser machine TruMatic 3000 fiber will also make its debut. For this purpose, the TruPunch 3000 was additionally equipped with a TruDisk 3001 with 3 kilowatts of laser power. This makes it the ideal solution for users who want to benefit from the flexibility of laser processing in addition to productive punching.

Less space, more throughput

The TruPunch/TruMatic 3000 is highly productive and economical even at medium capacity, promises Trumpf. The machine has a working area of 2,500 x 1,250 millimeters as a medium-format machine and over 3,000 x 1,500 as a large-format machine and processes sheets up to 6.4 millimeters thick. Thanks to the DeltaDrive concept, it achieves a nine percent higher throughput than its predecessor model. At the same time, the new machine is very compact with a footprint of just 30 square meters.

Punching rethought

The patented DeltaDrive eliminates the need to move the sheet and support table in the Y-axis. Instead, the punching head does this by “flying” over the sheet metal. The drive system for the DeltaDrive is powered by three servo motors. The highlight behind DeltaDrive: The system couples the punch drive with the Y-travel movement. Sheet metal and support table do not move. This ensures greater process reliability and higher productivity during punching.

© Trump

Automatic loading and unloading

The smooth material flow also contributes to the efficiency of the machine. Small parts fall automatically via a divider chute into up to four sorting boxes. In addition, the TruPunch/TruMatic 3000 has another, larger parts flap that can be used to discharge parts up to 400 x 600 millimeters in size into two containers.

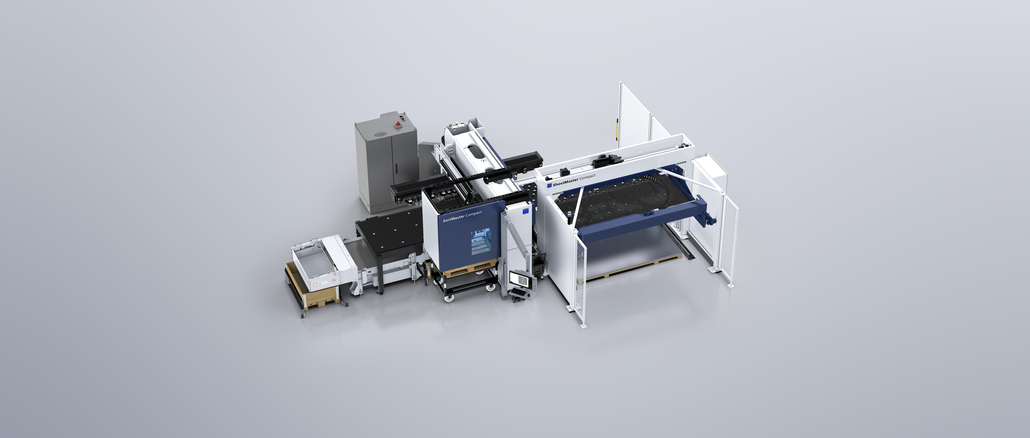

To ensure that nothing comes to a standstill during loading and unloading, the machine can be equipped with the SheetMaster Compact and the SortMaster Compact. This ensures automated loading of raw sheets and unloading of blanks, microjoint sheets and residual grids. The parts chute of the TruPunch/TruMatic 3000 automatically discharges and sorts good parts gently and reliably.

High parts quality

In addition, a lowerable die ensures excellent part quality. It moves down after the punching stroke. This prevents contact between the sheet and the die when the sheet is moved and avoids scratches during punching and forming operations.

In addition, the TruPunch/TruMatic 3000 is the first punching combination machine from Trumpf to feature an operating panel with a touchpoint interface. This increases the ease of use and simplifies tool management.

Laser machine with additional functions

According to Trumpf, the TruMatic 3000 fiber with the DeltaDrive and the TruDisk disk laser is particularly energy efficient. The TruDisk is also highly productive in the range of sheet thicknesses up to 6 mm. The laser makes the machine quick and easy to program. This means that even small batch sizes can be produced flexibly. The machine also scores with low investment costs and good economic efficiency.

Web:

www.trumpf.com