Laserline is presenting the entire spectrum of its diode lasers at Laser World of Photonics. In addition to trade fair innovations such as LDL direct diode lasers and fiber optic cables for high-performance applications, the main focus will be on realizing more efficient and sustainable machining processes.

Laserline will be presenting its extensive portfolio of industrial diode laser solutions at Laser World of Photonics (June 24 to 27, Munich, booth 311, hall B3). Trade fair highlights include the new LDL direct diode laser series for various heat treatments as well as fiber optic cables for cladding, welding, hardening, remote welding and cutting. Across all applications, the focus will be on optimizing the efficiency and sustainability of machining processes.

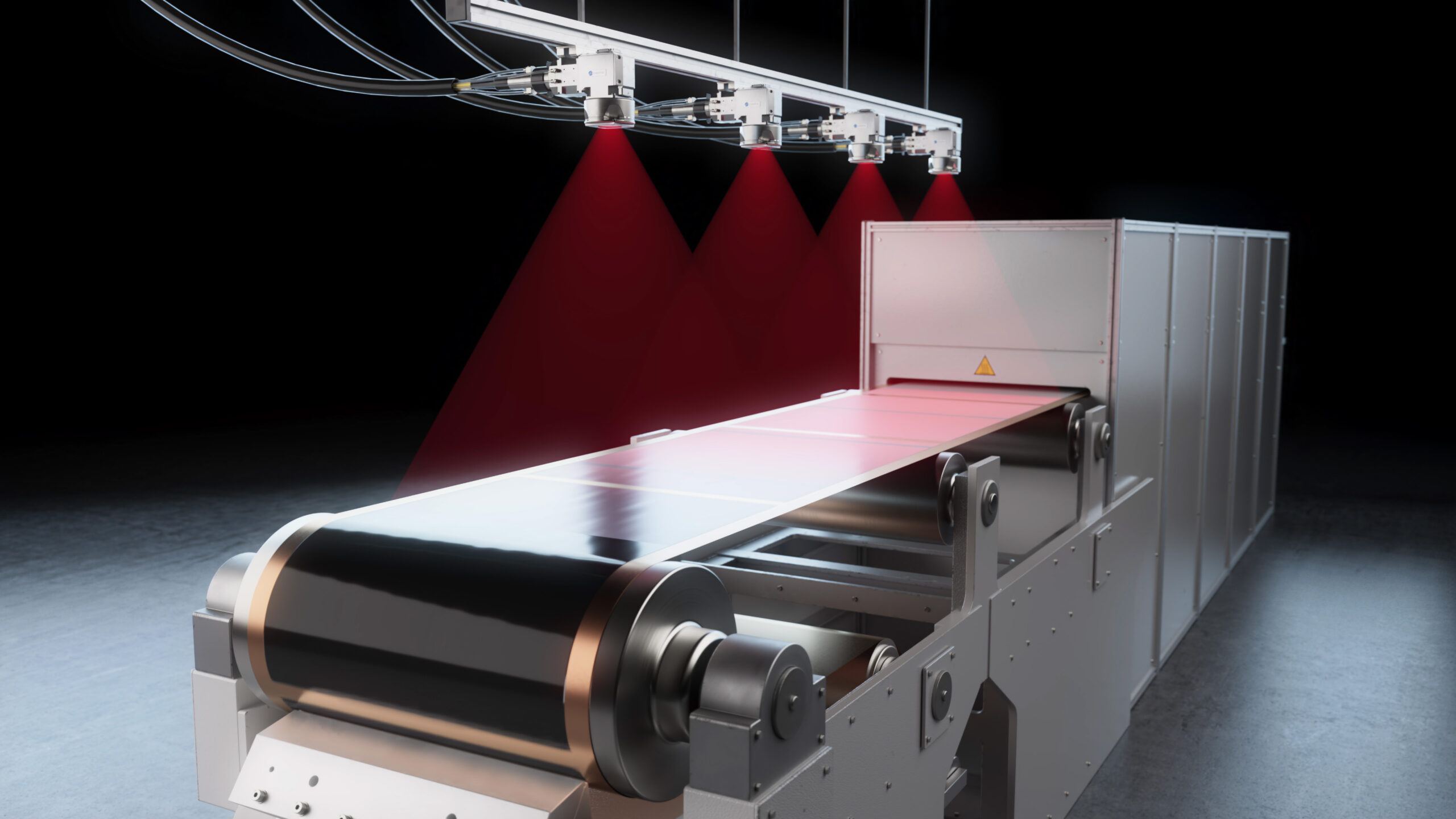

Modular direct diode laser systems for heat treatments

For example, the new LDL direct diode lasers with their direct photon emission and socket efficiency of over 56 percent are well suited for energy-efficient heat treatments such as drying or curing paints, battery electrodes, powder and polymer coatings as well as annealing semiconductor wafers and implementing sintering processes.

Due to their simple system architecture, LDL systems are not only comparatively inexpensive, but also easy to implement. The compact laser systems are currently available with output powers ranging from a few kilowatts to over 30 KW and typically have one to eight emission zones – however, the modular system design means that customized and tailor-made solutions can also be implemented. The segment output can be precisely controlled within milliseconds, which opens up a wide range of beam shaping options such as spot trimming. Visitors can get a detailed overview of the solution portfolio at the trade fair stand.

Fiber optic cable for high beam quality with high IR output power

Another trade fair highlight is the new APF fibers (Active Process Fiber). They have been specially designed for infrared processes that require very small focus diameters at high laser outputs. With their help, high beam qualities of 3 mm∙mrad and less can be achieved at 6 KW output power, for example. APF fibers are also suitable for hybrid systems in which the same beam source is used for several processes using two standard beam outputs. For example, a 1,000 µm standard fiber can be installed for large-area cladding or heat treatment applications with outputs of over 20 KW, while the second output is equipped with a 50 µm or 75 µm fiber for remote welding or cutting applications with an output of up to 6 KW. The fibers can be easily implemented via a plug-in connection, which increases process flexibility and ease of maintenance and reduces operating costs. The fibers are currently available in lengths of 20 and 25 m. A model of a hybrid system is part of the exhibition.

Beam shaping solutions for process optimization

Laserline will also be presenting beam shaping solutions for implementing more sustainable machining processes in the areas of coating, drying and heat treatment. The application-specific shaping of the laser beam makes it possible to process workpieces more gently while maintaining the same high process quality. Among other things, coating solutions for plain bearings and brake disks, solutions for drying battery foils, MultiWire optics for multi-wire coating applications and multi-spot modules for joining metal components will be on display at the stand.

Blue diode lasers for processing copper and gold

Various blue diode laser systems with a wavelength of 445 nm complete the trade fair presentation. Thanks to the excellent absorption rates in this spectral range, the lasers are particularly suitable for the energy-efficient and gentle processing of highly reflective metal types such as copper or precious metals. Among other things, a WBC (Wavelength Beam Combining) blade for powder bed and welding applications, which enables high beam qualities, and an LDMblue for processing copper will be presented at the Laserline stand.