At Euroblech, Laserline will be presenting highly efficient solutions for processing sheet metal, copper and aluminum components.

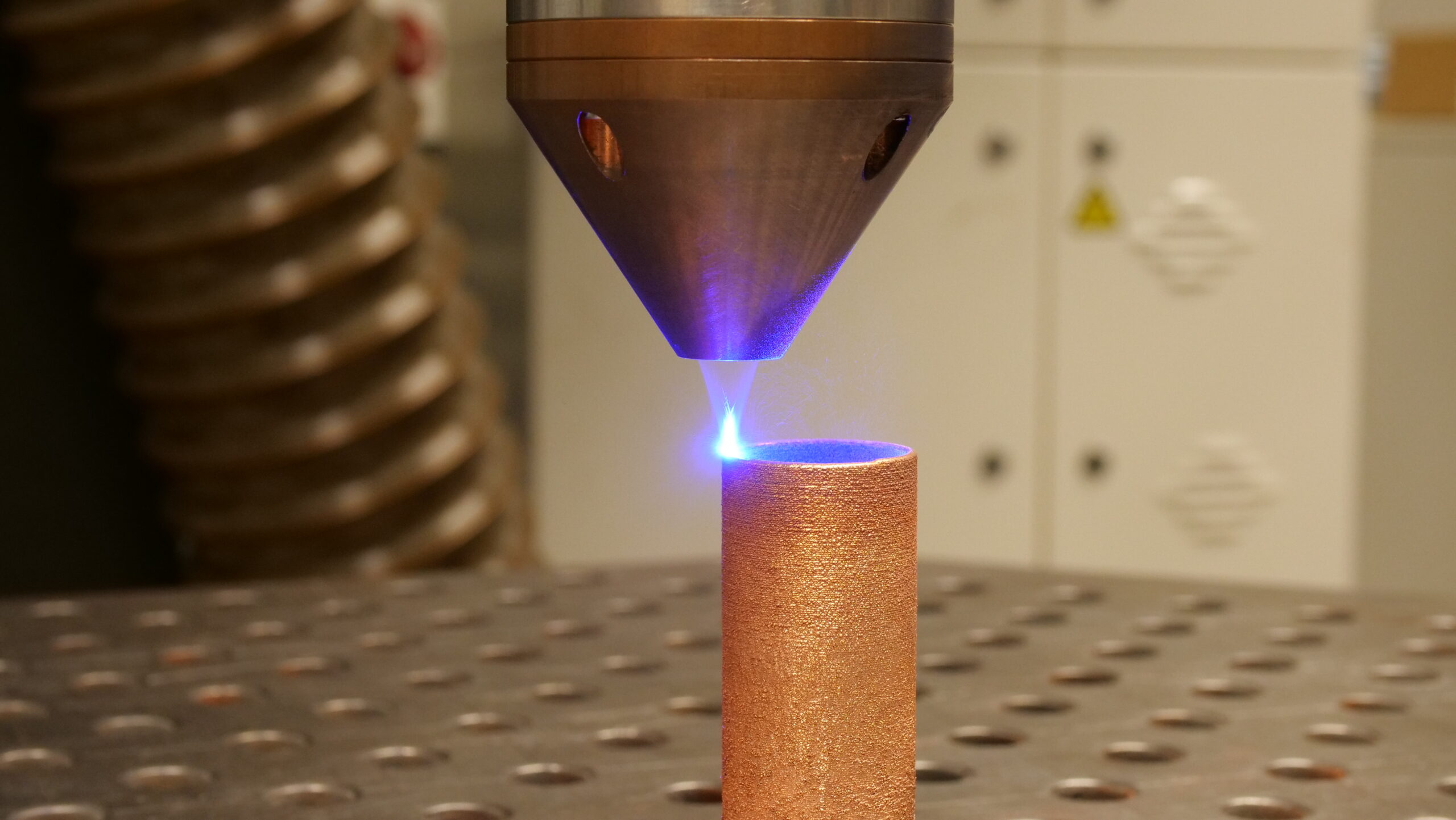

The focus will be on multi-spot optics for application-optimized beam shaping, blue 4 KW CW diode lasers for copper welding and solutions for laser curing of powder coatings.

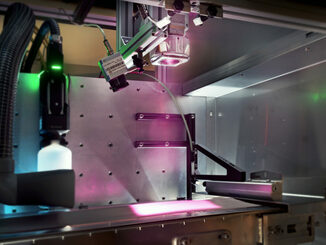

The trade fair highlights from diode laser specialist Laserline include multi-spot optics for application-optimized beam shaping. They enable beam splitting to generate several individual spots as well as spot-specific adjustment of geometry and intensity distribution. They are used, for example, for the smooth and fast brazing of hot-dip galvanized sheet metal or for the spatter-free creation of symmetrical or asymmetrical seams with an adapted penetration profile. Optics for aluminum welding with hot wire (Hot Wire Aluminum Welding) will also be presented. The process offers significantly greater process stability than conventional aluminum joining processes and scores points thanks to reduced heat input into the base material as well as high process speed with high seam qualities. In addition to processing optics, Laserline will also be exhibiting various beam sources: One focus will be on fiber-coupled mobile diode lasers from the LDF series, which offer output powers of more than 45 KW in various system configurations. The LDF lasers are characterized by their flexible scalability and can be easily upgraded in the field from 12 to 24 KW, for example. For the increasingly important industrial processing of non-ferrous metal components, Laserline is also presenting its portfolio of solutions in the field of blue high-power diode lasers – with peak outputs of up to 4 KW. Their wavelength of 445 nm is absorbed by copper and copper alloys five times better than infrared radiation, which ensures exceptionally smooth melting baths without pore formation. The LDMblue lasers are available with CW output powers of up to 2 KW and are particularly easy to integrate into machine and system concepts thanks to their space-saving 19″ format. Another focus is the laser curing of powder coatings using the “Ultra Wide Spot” irradiation technology, an economically and ecologically convincing alternative to gas-powered oven processes. Laser irradiation only ever heats the exact area that is actually to be coated, without stirring up particles. As the laser systems require no preheating time and the laser power can be adjusted within milliseconds while the process is running, a 90 percent increase in the heating rate and a significantly higher overall energy efficiency can be achieved. Laserline will also be showcasing energy and material-efficient coating solutions, including for brake disks in road vehicles. The laser coating ensures long-term corrosion and wear protection and thus reduces the amount of particulate matter induced by the braking process, which is harmful to the environment and health, by up to 90 percent – making a decisive contribution to more sustainable mobility.

The trade fair presentation will be rounded off with selected exhibits from individual application areas, including an underride guard for a car and samples for welding tailored blanks. Web: www.laserline.com

Euroblech Hall 26, Stand J52