The IDEEL research project aims to launch a laser drying process for the more climate-friendly and economical series production of lithium-ion batteries. In this context, it has now been possible for the first time to produce laser-dried anodes and LFP cathodes in a roll-to-roll process. The innovative manufacturing process significantly reduces energy requirements in electrode production and at the same time enables the drying speed to be doubled.

As part of the IDEEL research project (Implementation of Laser Drying Processes for Economical & Ecological Lithium Ion Battery Production) under the leadership of Laserline GmbH, the production of laser-dried anodes and LFP cathodes in a roll-to-roll process has been achieved for the first time. Based on industry-relevant electrode pastes, the PEM (Production Engineering of E-Mobility Components) was able to demonstrate processability of aqueous LFP cathodes and anodes in the prototype system at the “eLab” of RWTH Aachen University. In cooperation with the MEET (Münster Electrochemical Energy Technology battery research center), the quality properties were evaluated and optimized electrode pastes were developed.

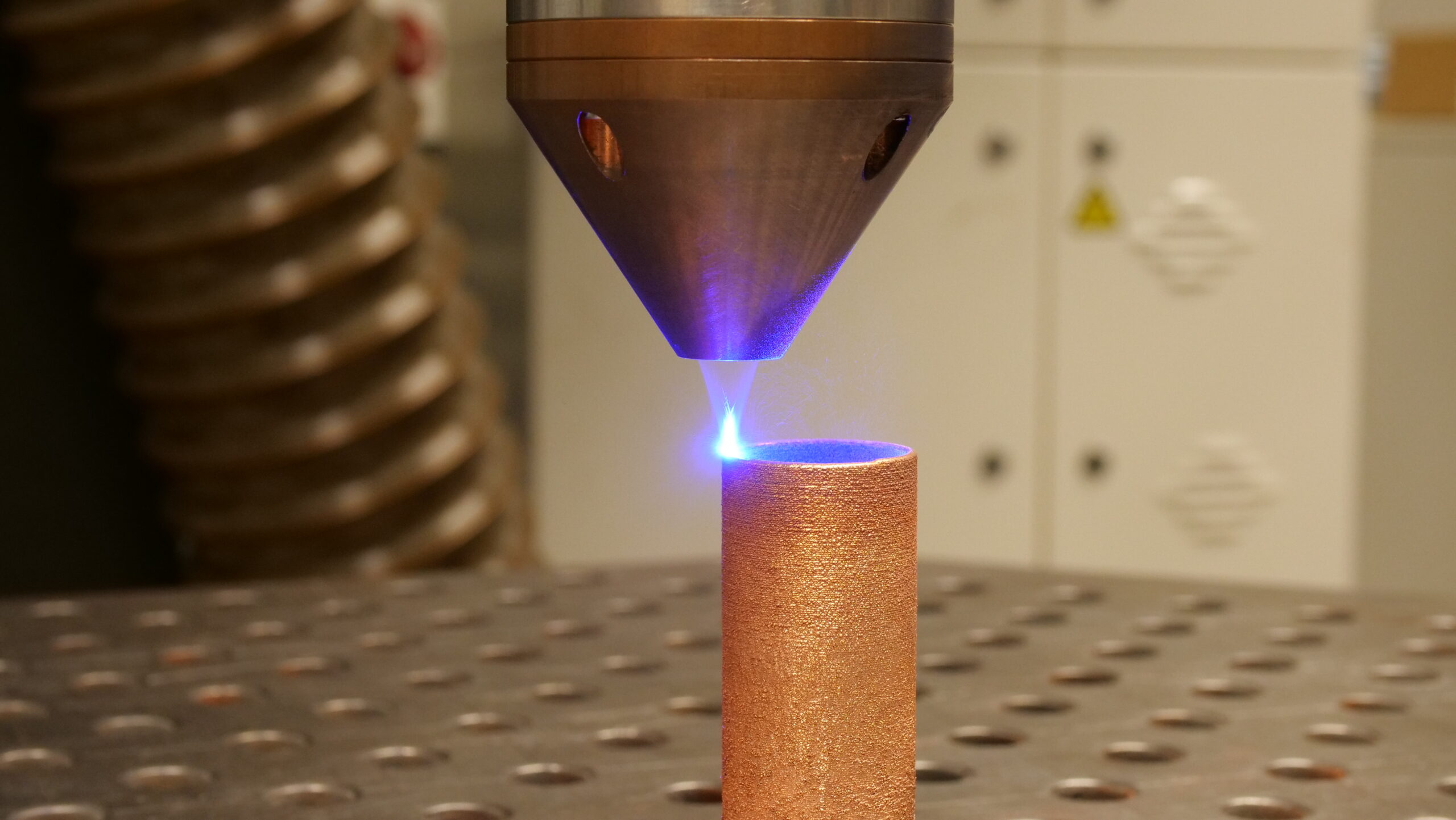

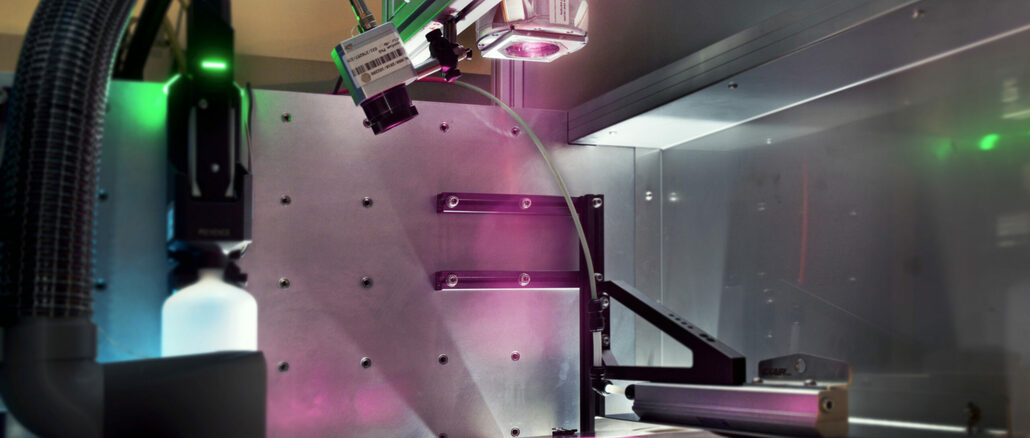

For the demonstration tests, a Laserline high-power diode laser with zoom optics was integrated into the film coating line there to create a homogeneous laser spot for drying the active material. The temperature distribution on the electrode was monitored using a thermographic camera from Optris GmbH. Proof-of-concept was performed at a web speed of 1.3 m/min, with both laser-only drying and hybrid drying with laser and downstream convection oven successfully demonstrated.

According to initial results, the innovative manufacturing process reduces energy consumption in electrode production by up to 85 percent when using laser drying alone. The investigation of the hybrid process also showed that, compared to pure convection drying, a doubling of the drying speed could be achieved by adding a laser station. Overall, battery production can thus be made more cost-effective and sustainable. Comparative benchmark analyses of the quality properties (residual moisture of the active material, adhesion of the coating to the carrier film) of convection- and laser-dried electrodes confirmed this increase in productivity. The project results to date demonstrate that the process approach is not only suitable for new plants, but also that existing convection ovens can be retrofitted with appropriate laser drying technology.

In the further course of the project, it is planned to scale up the web speed to 10 m/min (Fraunhofer ILT) and to 30 m/min at the end of the project (Coatema Coating Machinery GmbH). To this end, Laserline is currently developing optics to generate a large-area laser spot. Initial research results also indicate that, in perspective, it will be possible to reduce the size of the plant to one-tenth.

Web:

www.laserline.com