The results are clear. AP&T’s Multi-Layer Furnace is very suitable for press hardening sheet metal with a strength in the range of 1800 to 2000 MPa, as shown by tests that AP&T recently carried out with ArcelorMittal to investigate the risks of hydrogen embrittlement.

By using ultra-high-strength steels with a lower thickness for press-hardened components, vehicle manufacturers can further reduce the weight of vehicles – and therefore energy consumption – while maintaining or even increasing safety.

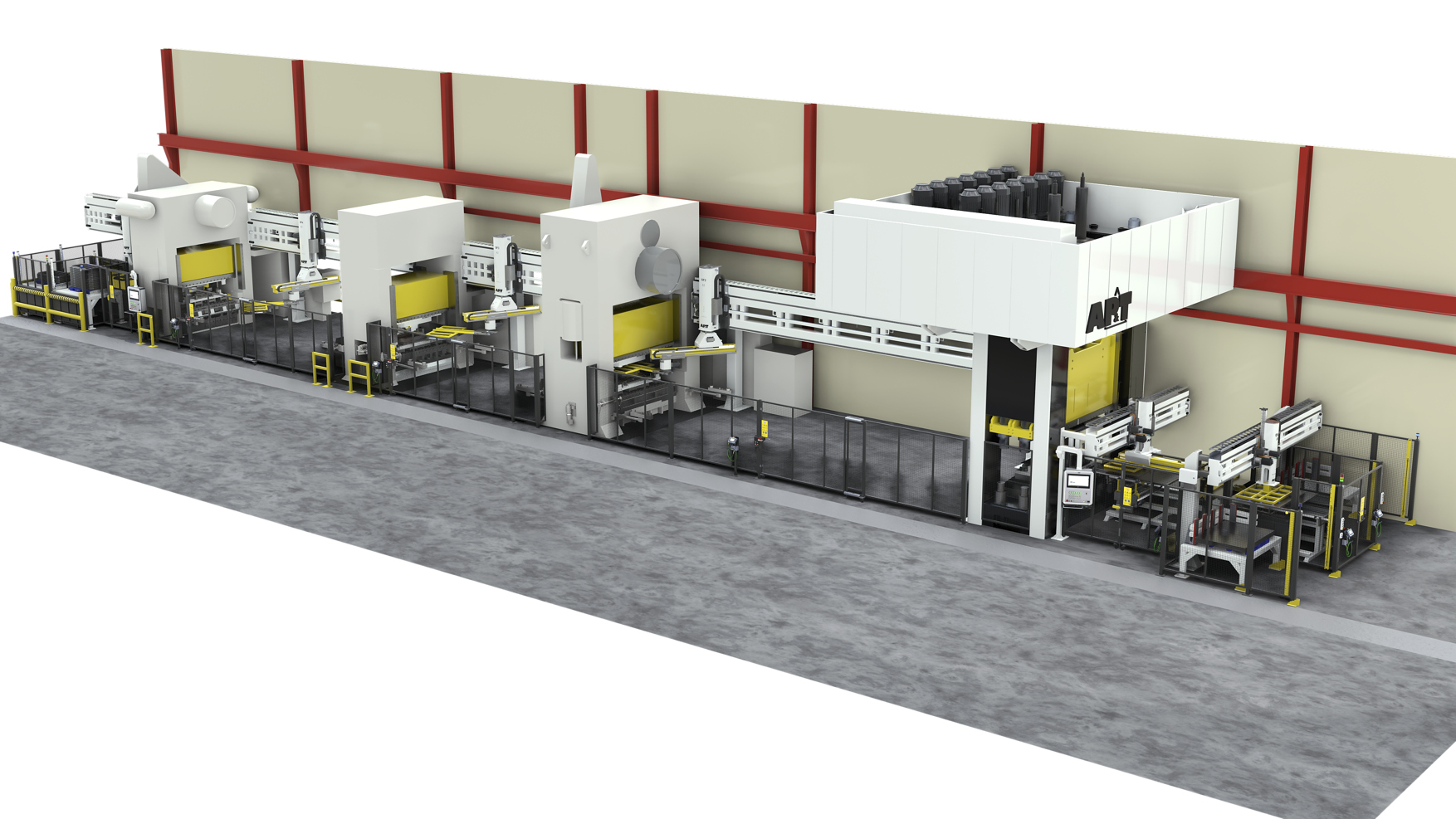

© AP&T

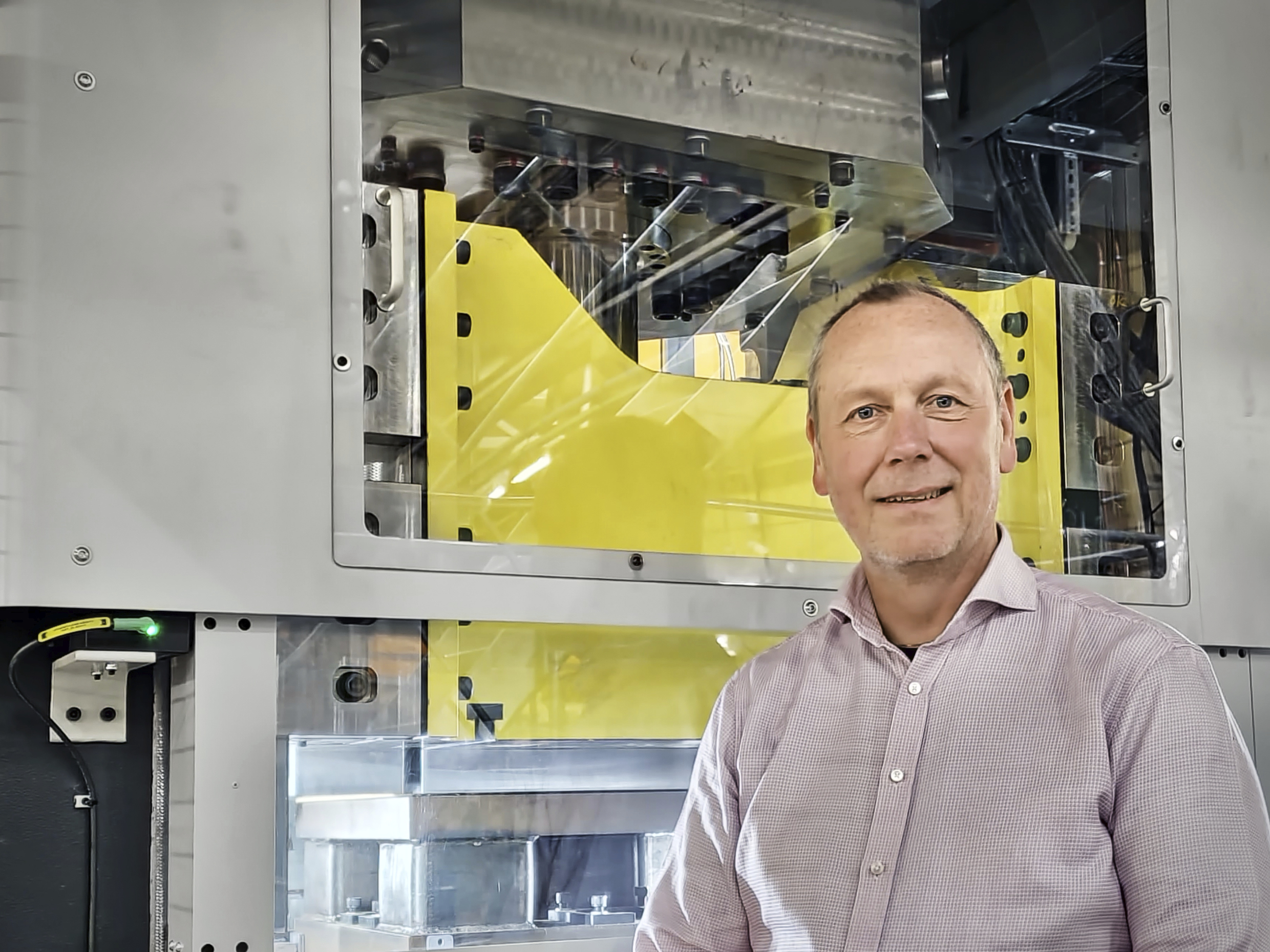

However, steel with a tensile strength of up to 2000 MPa also places higher demands on process control and monitoring in order to reduce the risk of so-called hydrogen embrittlement. This phenomenon occurs when hydrogen from the ambient air penetrates the sheet during heating, making it more brittle and susceptible to cracking. Hydrogen embrittlement is a particular problem in the automotive industry, especially in hot and humid countries where press-hardened steel components are manufactured. To minimize this risk, it is important to control the dew point of the furnace air, i.e. the temperature at which the air is saturated with moisture and water vapour begins to condense into liquid water. How sensitive is the process? Together with the steel manufacturer ArcelorMittal, AP&T recently tested press-hardened components produced with the ultra-high-strength Al-Si coated material Usibor 2000 AS in a multi-layer furnace in a humid environment. The aim was to find out whether the dew point control of the furnace by blowing dry air is efficient enough to prevent hydrogen embrittlement even under the most unfavorable conditions. In AP&T’s development department in Ulricehamn, Sweden, a climate chamber was built around the furnace used for the tests. A relative humidity of 70 percent and a temperature of 30 °C prevailed. When the oven door is opened and the material is inserted, air from the environment enters. Dry air is blown into the chamber to lower the humidity and thus regulate the dew point. A series of tests were carried out in which both large and small quantities of dry air were fed in as the oven temperatures increased. When the sheet metal blanks are taken out of the oven, they have a temperature of around 900 degrees. In the next step, they are pressed and quenched in a mold at around 80 degrees. Within two days of the tests being completed, the samples were stored in dry ice and transported to France for analysis at ArcelorMittal. And the result? The results showed that the hydrogen content in Usibor 2000 AS remained low at around 0.1 ppm, regardless of whether large or small amounts of dry air were blown into the process. Conclusion: The dew point control system of AP&T’s Multi-Layer Furnaces with dry air injection is efficient in minimizing hydrogen absorption in aluminized press hardening steels and is therefore very suitable for the safe production of parts made of aluminized press hardening steels with strengths of up to 2000 MPa. Web: aptgroup.com