Electrification, multi-part integration and a higher proportion of recycled material. Technological change in the automotive industry is driving development and posing new challenges. The new AP&T Skylines press hardening line has been developed to meet these challenges and pave the way for more effective, flexible and sustainable vehicle production.

It is no news that the automotive industry is currently undergoing massive change. Skylines is a fully automated line that has been specially developed for the effective press hardening of large and oversized sheets and Multi Part Integration (MPI) – complex, integrated components – including materials with a high recycled content.

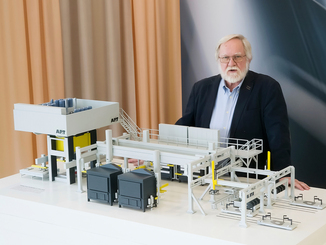

© AP&T

Space-saving design and greater flexibility

To maximize production capacity for large-format sheets with minimal energy consumption, AP&T Skylines has a flexible, vertical design that uses a modular and scalable solution. The line therefore only requires a small footprint, although it includes energy-efficient servo presses, compact multi-layer furnaces, flexible linear automation with speed feeders, high-quality tools and associated comprehensive service solutions such as availability agreements. Each part is designed to meet specific customer requirements and ensure long-term performance.

“AP&T Skylines is the result of our efforts to help our customers meet both technical and environmental requirements. With Skylines, we offer them a solution that combines sustainability and efficiency without compromising on performance,” explains Magnus Baarman, Managing Director and CEO of AP&T.

One of the most outstanding features of AP&T Skylines is the compact and energy-efficient MLF system. In contrast to conventional roller hearth furnaces, this vertical system can process much larger sheets and more complex components without being restricted by the dimensions of the furnace. It is also characterized by significantly lower energy consumption and considerably lower CO₂ emissions, making it a key component of a sustainable production process.

The potential to revolutionize the automotive industry?

As demand for large-format and integrated components grows, AP&T Skylines offers a solution that optimizes space, material and resource utilization while streamlining production. Fewer tool changes, shorter throughput times and lower energy consumption improve both competitiveness and sustainability in the automotive industry.

“Skylines sets a completely new standard for the automotive industry. With this flexible and scalable technology, we enable manufacturers to overcome technical and environmental challenges at the same time. Skylines is a next-generation press hardening line that strengthens manufacturers’ position in the global market,” says Magnus Baarman from AP&T.

Web:

aptgroup.com