To ensure maintenance work is carried out safely, the new “Key-in-pocket” maintenance safeguard from Pilz protects operators from unauthorized restarting of a machine. Digital maintenance protection based on the PITreader access authorization system ensures safety and industrial security: only authorized persons can access the machine or system during the maintenance process – manipulation and incorrect operation are ruled out.

Sprawling facilities often have a variety of hazardous areas that are secured with protective fencing. This places special demands on safety: It is important, for example, that only authorized persons have access for maintenance work. At the same time, it must be ensured that no persons are still in the danger zone when the system is restarted.

Pilz presents “Key-in-pocket”, a digital maintenance safeguard that flexibly solves both safety and industrial security requirements: “Key-in-pocket” ensures that the machine does not restart during maintenance work and that unauthorized persons cannot gain access. The solution thus offers safety against dangerous restarts and at the same time industrial security, since it is not possible to manipulate the maintenance work.

Authentication as a basis

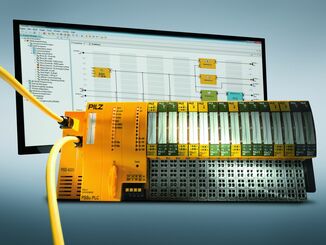

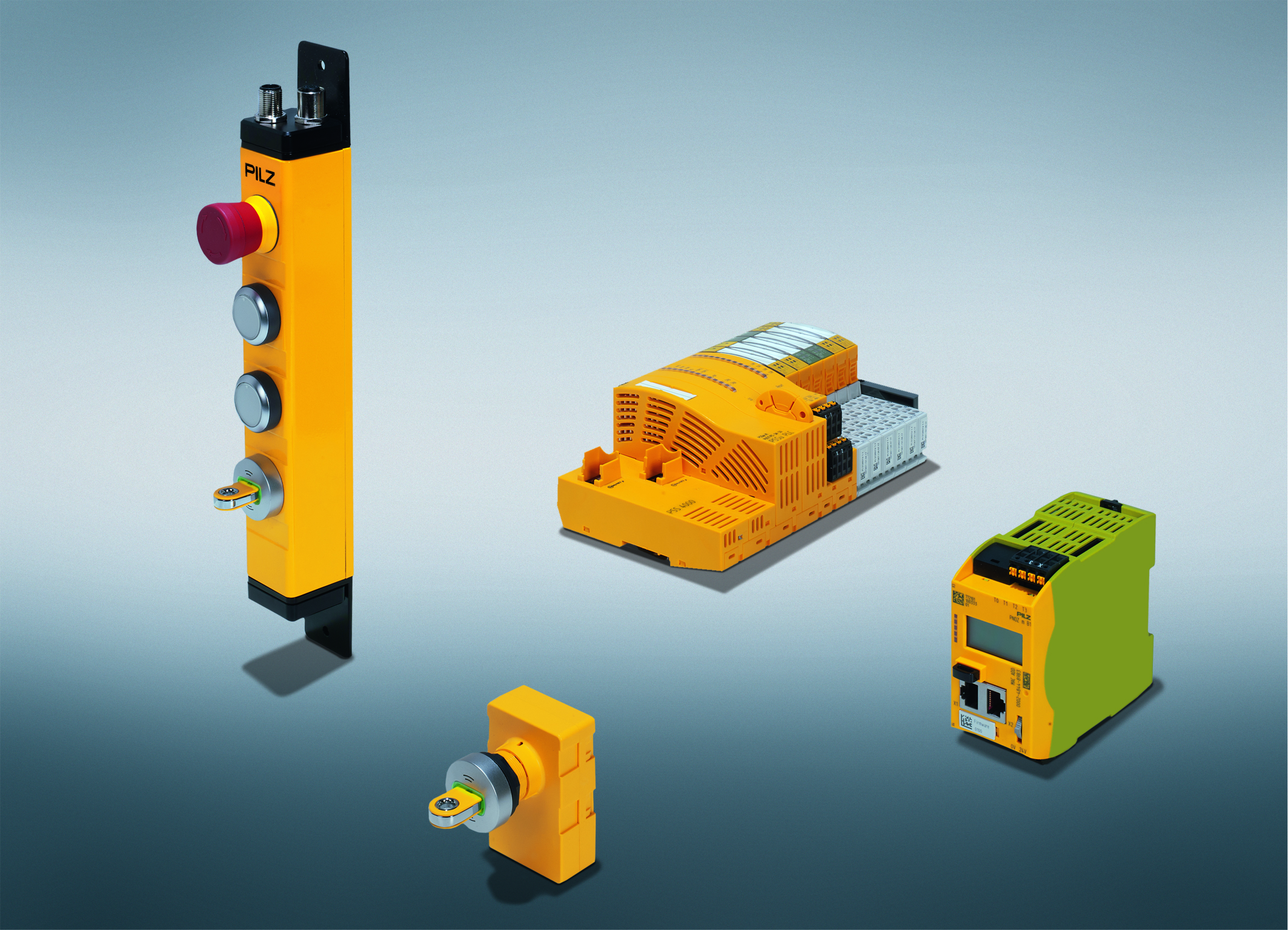

“Key-in-pocket” is based on the PITreader access authorization system and is implemented with the configurable mini control system PNOZmulti 2 or the automation system PSS 4000. Users receive their individual authorizations on an RFID key, which are read out with PITreader at the safety gate. This allows one or more users authorized for maintenance work to authenticate themselves to the system. The operator knows at any time who gets access for which task and can also assign temporary permissions. After successful authentication, a personalized security ID is stored in a secure list in the controller for the user. The machine can now be switched off, the safety door opened and the machine entered. Meanwhile, the RFID keys remain “in the pocket” of the respective users – “key-in-pocket”. After maintenance has been carried out and after leaving the hazardous area, all personnel log out, the security IDs are removed from the Pilz control system’s safe list and the machine can be restarted.

Simply maintain safely

The digital maintenance fuse is specially designed for machines with hazardous areas protected by safety fences. It provides an economical, efficient alternative to mechanical lockout tagout maintenance guards that are installed on all safety gates. Since the plant can be entered or exited at various safety gates, “Key-in-pocket” offers personnel more flexibility and thus time savings during maintenance.

Background

The Pilz Group is a global supplier of products, systems and services for automation technology. The family-owned company with headquarters in Ostfildern employs around 2,500 people. With 42 subsidiaries and branches, Pilz creates safety for man, machine and environment worldwide.

The technology leader offers complete automation solutions comprising sensor, control and drive technology – including systems for industrial communication, diagnostics and visualization. An international range of services including consulting, engineering and training rounds off the portfolio. Solutions from Pilz are used in numerous industries beyond mechanical and plant engineering, such as intralogistics, railroad technology and robotics.

Web:

www.pilz.com