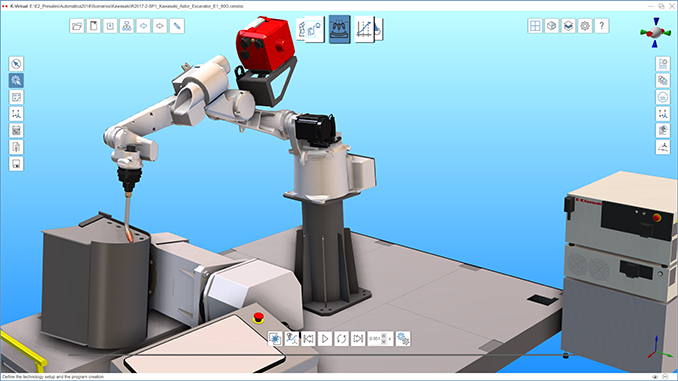

Based on Cenit’s proven Fastsuite technology: K-Virtual enables agile development, programming and optimization of complex robot applications via an intuitive platform.

With the K-Virtual tool, Kawasaki Robotics will offer a new software solution for efficient plant engineering, practical robot simulations and convenient offline programming from September 1, 2020. K-Virtual will be released in several editions – from Basic to Expert – and optimized for various applications such as arc welding. Companies are thus able to fully exploit the complete performance capability of their Kawasaki robots within individual automation solutions – from initial installation to reprogramming and re-engineering of the system.

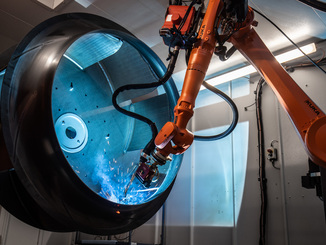

Image: © Kawasaki Robotics

K-Virtual was developed together with the long-time partner Cenit on the basis of the Cenit Fastsuite Edition 2.

In addition to 50 years of robotics expertise from Kawasaki Robotics, more than 30 years of experience as a software provider in the field of the digital factory have gone into the new tool. Carsten Stumpf, Vice President at Kawasaki Robotics Germany, explains: “Industry 4.0 requires new approaches and concepts. Virtual factories and plant models must be an exact representation of real production systems in every respect. With Cenit we have the right partner to offer our customers the optimal tool for planning individual automation.

Kawasaki robots are used in numerous complex manufacturing processes – from semicon to automotive.

Demanding applications are difficult to implement with the required process quality and efficiency via manual programming. Simulation-based solutions therefore play an increasingly important role in the implementation of new plant concepts or manufacturing processes. With K-Virtual as an intuitive and agile 3D simulation platform, Kawasaki Robotics offers its customers a tool for future-proof planning of their automation processes.

Kurt Bengel, CEO of Cenit AG, also sees the cooperation with Kawasaki Robotics positively: “In our strategy to enable agile manufacturing technologies and production concepts with our own software, this partnership is a new milestone. We are looking forward to the innovative cooperation!

Kawasaki Robotics, with its Emea headquarters in Neuss, Germany, is a leading global supplier of industrial robots and robotic automation systems covering a wide range of applications around the world. With more than 50 years of robot experience and an extensive portfolio, Kawasaki supplies robots for all industries from Semicon to Automotive.