Last year, Alfred Wagner Stahl-Technik & Zuschnitt had already expanded production with an Element flame-cutting machine from Messer Cutting Systems, generating enthusiasm among both customers and employees. Building on this success, the decision was made to further modernize the machinery – this time with a particularly robust OmniMat, which is well suited to complex applications.

As part of its strategy for the future, Alfred Wagner Stahl-Technik & Zuschnitt GmbH, based west of Linz on the Danube, is once again relying on its technological partnership with Messer Cutting Systems Austria to replace an existing system with state-of-the-art cutting technology. This project marks the next important milestone in the company’s development and shows how technology and expertise can go hand in hand.

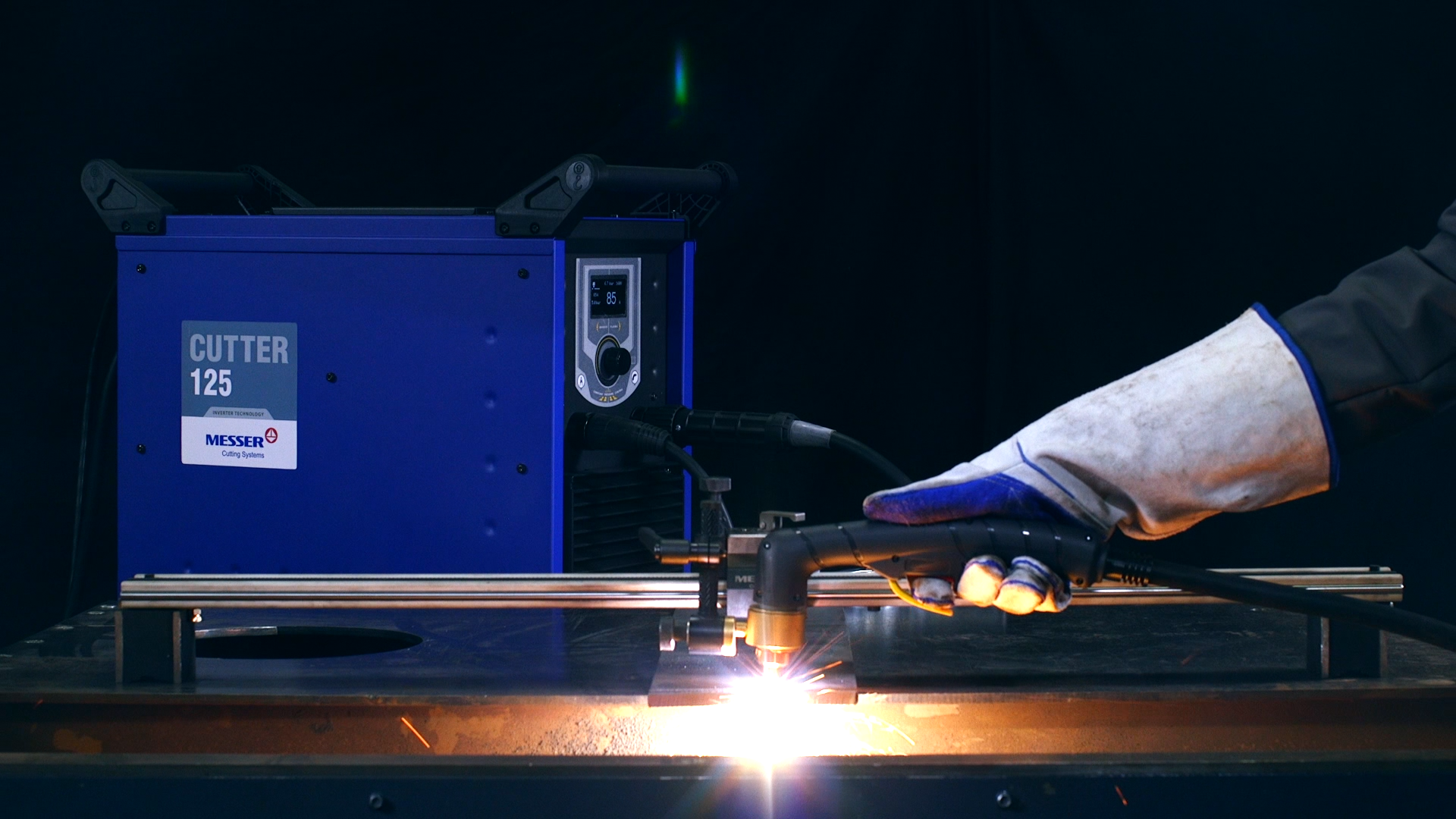

© Messer Cutting Systems

The challenge: setting new standards

“On the one hand, our existing system was getting on in years. And secondly, we wanted to simplify our processes and increase productivity with an additional drilling unit,” explains Christian Aufreiter, Operations and Project Manager at Alfred Wagner Stahl-Technik & Zuschnitt.

In addition to the integration of the drilling unit, there were other ambitious goals to be achieved with the new project: The existing system was to be replaced with minimal loss of production. The existing cutting table and extraction system were to continue to be used. Maximum reliability with first-class cutting quality with the new system as well as ease of operation and a short training period for the employees were also at the top of the specifications.

After carefully evaluating the market offerings, Wagner opted for the OmniMat from Messer Cutting Systems. The heavy-duty CNC cutting machine combines modern technology, intuitive operation and high precision. For Wagner, the machine was equipped with a drilling unit, a triple changer and four Alfa torches, which enable cuts of up to 300 mm.

The OmniMat has been specially designed for demanding applications in metal processing. It offers working widths of up to 13,000 mm and is suitable for various cutting processes such as oxyfuel, underwater or dry plasma cutting as well as processes such as marking and drilling. Thanks to its robust gantry design and precise guide profiles, it guarantees high cutting accuracy and contour fidelity, even under the toughest production conditions. The open OPC UA interface on the Global Control system enables simple connection to modern Industry 4.0 environments and efficient monitoring and control of machine processes.

With its many sophisticated features and options, the Alfa torch takes oxy-fuel cutting to a new level. The burner nozzle can be changed without tools, which drastically reduces set-up times. The burner effectively cuts right to the edge of the plate, ensuring better material utilization. In addition, the height sensing is insensitive to slag, scale and moisture as it is magnetic and fully integrated into the torch. The drilling unit is used when greater drilling accuracy is required, the drilling diameter is less than the material thickness or the number of thermal piercings is to be reduced.

“The OmniMat was the logical choice for us. We have already had very good experiences with the first machine from Messer Cutting Systems, the Element. We were impressed by the quality and service,” explains Christine Wagner, Managing Director of Alfred Wagner Stahl-Technik & Zuschnitt GmbH.

The difference: efficiency, economy and sustainability

Numerous work processes have been optimized with the new system. The drilling unit has significantly increased productivity. “Previously, we had to pierce starting holes for oxyfuel cutting processes up to 200 mm with the torch or drill them manually. This was time-consuming and put a strain on the machine. Now we can easily pre-drill start holes from 80 mm material thickness and cut the smallest contours even in thick materials,” says Christian Aufreiter, describing the improvements.

Another advantage: thanks to the intuitive operability of Global Control, the machine operators were able to take over the new system without any problems. “This shows how user-friendly and well thought-out the system is,” emphasizes Christine Wagner.

In addition to higher productivity, the new system saves costs and extends the service life of the entire system. “The modern drilling unit protects the machine and reduces maintenance intervals. This is a great advantage in our daily operations,” confirms Christian Aufreiter.

© Messer Cutting Systems

A project straight out of the textbook

The course of the project was a prime example of professional cooperation. From delivery to installation, everything went according to plan. “The installation went smoothly and the timing was perfectly coordinated,” praises Christian Aufreiter. Wagner also highlighted the cooperation with Gerhard Wimmer, Head of Messer Cutting Systems Austria: “Mr. Wimmer and his team were always there for us. They not only provided us with excellent support during the installation, but also during the training and start-up of the new machine.”

Gerhard Wimmer is also delighted with the partnership: “It is always a pleasure to work with companies like Alfred Wagner Stahl-Technik & Zuschnitt. Their commitment to quality and innovation fits perfectly with our values at Messer Cutting Systems.”

The team at Wagner Stahl-Technik & Zuschnitt is convinced that investing in modern technologies is the key to long-term success. At the same time, there is still room for improvement. The company is optimistic about future developments. “The demands for flexibility, speed and precision are constantly increasing. With the new system, we are ideally positioned to master these challenges,” concludes Christine Wagner.

A win-win situation across the board: innovation and collaboration pay off

The project between Alfred Wagner Stahl-Technik & Zuschnitt GmbH and Messer Cutting Systems Austria is an example of a successful partnership between companies and technology providers. With the OmniMat, the company has not only been able to make its processes more efficient, but has also taken an important step towards the future. “We are extremely satisfied with the performance of the new machine and the cooperation with Messer Cutting Systems. This investment has paid off for us in every respect,” sums up Christine Wagner.