The recent acquisition of long-time robotics partner Sistec AM expands Prima Power’s expertise in technology integration to further strengthen its customer-centric offering. Sheet metal fabricators can now realize their potential through the complete optimization of robotic cells and the widest range of modular solutions for automated systems – all from one partner.

© Prima Power

Prima Power is taking a new step towards full automation – the latest step in its “Evolve by integration” strategy. The acquisition of robot specialist and established partner Sistec AM, with its highly specialized expertise, strengthens integration to a higher level of optimization, both in terms of flexibility and performance.

Development continues to focus on the specific needs of individual companies. The new internal robotics integration unit opens up the countless possible combinations of the extensive range of sheet metal technologies, from advanced robotic cells to flexible manufacturing systems that streamline the entire production flow. The benefits can include higher productivity, more flexible and compact layouts, smarter handling and logistics or wiser use of employee time.

In a manufacturing world that has long struggled with a labor shortage, robotic technologies are becoming more and more commonplace: the future is not in robotics per se, but in the quality and scope of robot integration. In this scenario, Prima Power will make life easier for manufacturers. Regardless of their challenges, OEMs and job stores of all sizes can find the expertise and the right technologies for their needs in a single comprehensive partner.

Thanks to its complete range of sheet metal processing machines and specialized robotics integration unit, Prima Power believes it holds a rare position: the ability to always design and deliver the solutions that best meet customers’ needs.

© Prima Power

The robotic bending cells have been developed to transform sheet metal processing by integrating advanced robot technology with servo-electric press brakes and panel benders. This combination ensures high repeatability and a fast return on investment, making it profitable for both small and large batches.

The flexibility of Prima-Power bending cells allows them to process a variety of materials and thicknesses and adapt to a wide range of applications. Their modular design allows for easy customization and scalability to meet the specific requirements of different manufacturers and job shops, regardless of their size. With fully automated operation, high precision and optimized layouts, the robotic solutions increase efficiency, reduce errors and simplify factory integration.

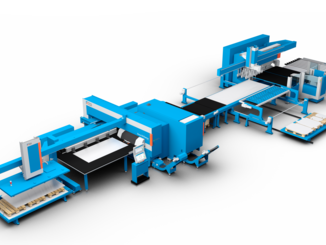

The robotic integration solutions are designed to increase efficiency, flexibility and productivity in sheet metal production. By seamlessly combining anthropomorphic industrial robots with a wide range of technologies in robotic cells or complete flexible manufacturing systems, Prima Power’s solutions optimize every step of production, from material handling to assembly, while ensuring a compact, scalable and high-performance system design.

The in-house Robotics Integration Unit specializes in the development of process-oriented solutions that simplify and optimize the production flow. These solutions enable manufacturers to streamline the production flow, shorten cycle times and improve overall output.

End-user benefits include fully integrated material handling automation, flexible and modular configurations, smarter use of manpower, optimized layouts and improved efficiency. Prima Power’s robotic integration solutions are extremely versatile and can handle a wide range of materials and material thicknesses. Thanks to their modular framework, these solutions are easily customizable and scalable, allowing them to adapt to the evolving needs of businesses of different industries and sizes and realize their full productivity potential.

Background

Prima Power offers companies of all sizes targeted dynamic technologies to increase profitability in sheet metal processing. The company creates integrated automated solutions tailored to customers’ challenges and open to their future growth. Prima Power offers high-performance machines designed to enable flexible and precise execution. The offering is based on a complete range of modular solutions, leveraging a distinctly customer-centric approach and a long-standing knowledge of technical systems and machines for sustainable, efficient manufacturing – all based on a unique history of technological integration. Prima Power’s technology offering is one of the most comprehensive in the industry: 2D and 3D laser machines for cutting, welding and drilling, punching machines, combined punch-laser and punch-shear systems, press brakes, panel benders, robotic bending cells and flexible manufacturing systems.

Prima Power is the sheet metal processing brand of Prima Industrie, an industrial innovation group with 1,900 employees, 15,000 systems, eight plants and an annual turnover of over 550 million euros.

Web:

primapower.com