Prima Power’s presence is fully in line with the motto of the 26th EuroBLECH “Your gateway to a smarter future”. Prima Power invites all visitors to take a “journey into the future of manufacturing”.

Automation and digitization are on the rise in all industries, regardless of company size. More and more sheet metal fabricators are turning to these trends to increase productivity, shorten lead times, improve the accuracy and quality of fabricated parts, reduce scrap, and improve ergonomics and safety for workers. The benefits of automated and intelligent production are key to addressing key challenges in the manufacturing industry, such as skills shortages, high quality requirements, material costs, delivery reliability, efficiency as well as sustainability.

Of course, solutions must be selected according to the specific needs of their business and be flexible enough to keep pace with the company’s growth and ever-changing market requirements. Prima Power, with a wide range of modular and flexible technologies, automations and software, as well as its long experience, can provide the right solution for a wide range of production requirements and investment sizes.

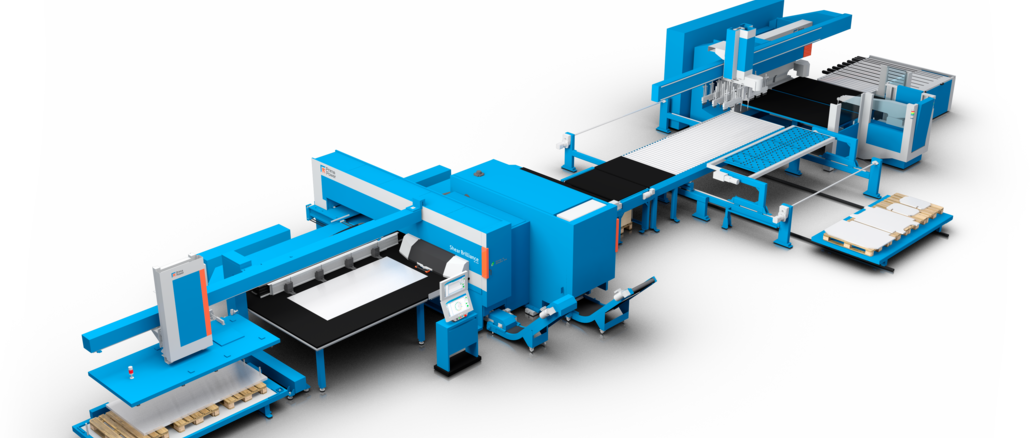

Highly automated production line

Highly automated production line

The highly automated production line on display at Euroblech is the compact PSBB Flexible Manufacturing System, which integrates the processes of punching, shearing, buffering and bending in a single solution. It is equipped with the new and efficient Shear Brilliance and the latest version of the EBe panel bender. The PSBB line utilizes decades of experience in FMS technology and automatically processes raw sheets into finished bent, high-quality components. It offers high productivity, accuracy and efficiency by using servo-electric technology for punching, shearing and bending, automatic flexible material flow and advanced software. The PSBB line is ideally suited for the production of angled parts and blanks and can therefore also be used, for example, in the manufacture of HVAC, door and elevator panels.

The new Shear Brilliance combined punching and shearing system, which is part of the line, relies on the latest composite materials, servo-electric drive and linear guides in its design to deliver truly impressive performance that translates into high productivity for versatile and flexible manufacturing. The advantages of modern servo-electric technology are low energy consumption and low maintenance requirements, as well as high accuracy and versatility. Modularity enables fast, high-precision production of components that also need to be formed – even bent, drilled and marked – in a single, flexible cell and in a fully automated process. The integrated punch-shear concept can deliver savings of 10 to 20 percent in raw material consumption. Even greater savings can be achieved with the optional cut-to-length line.

Servo electric swing bending machine

The PSBB line on display at the show includes the EBe2720, a fully automatic servo-electric swing bending machine that offers high throughput. Thanks to its integration with the FM system, it increases productivity by reducing the entire manufacturing process to a single step. Furthermore, it has a unique compact layouts. EBe is equipped with a PCD pick-up and centering device, a multifunctional table for positioning and centering parts, which allows the flow of material from other machines in the line; in addition, the BTD bending and turning device automatically turns the sheets in a hidden time before the bending process.

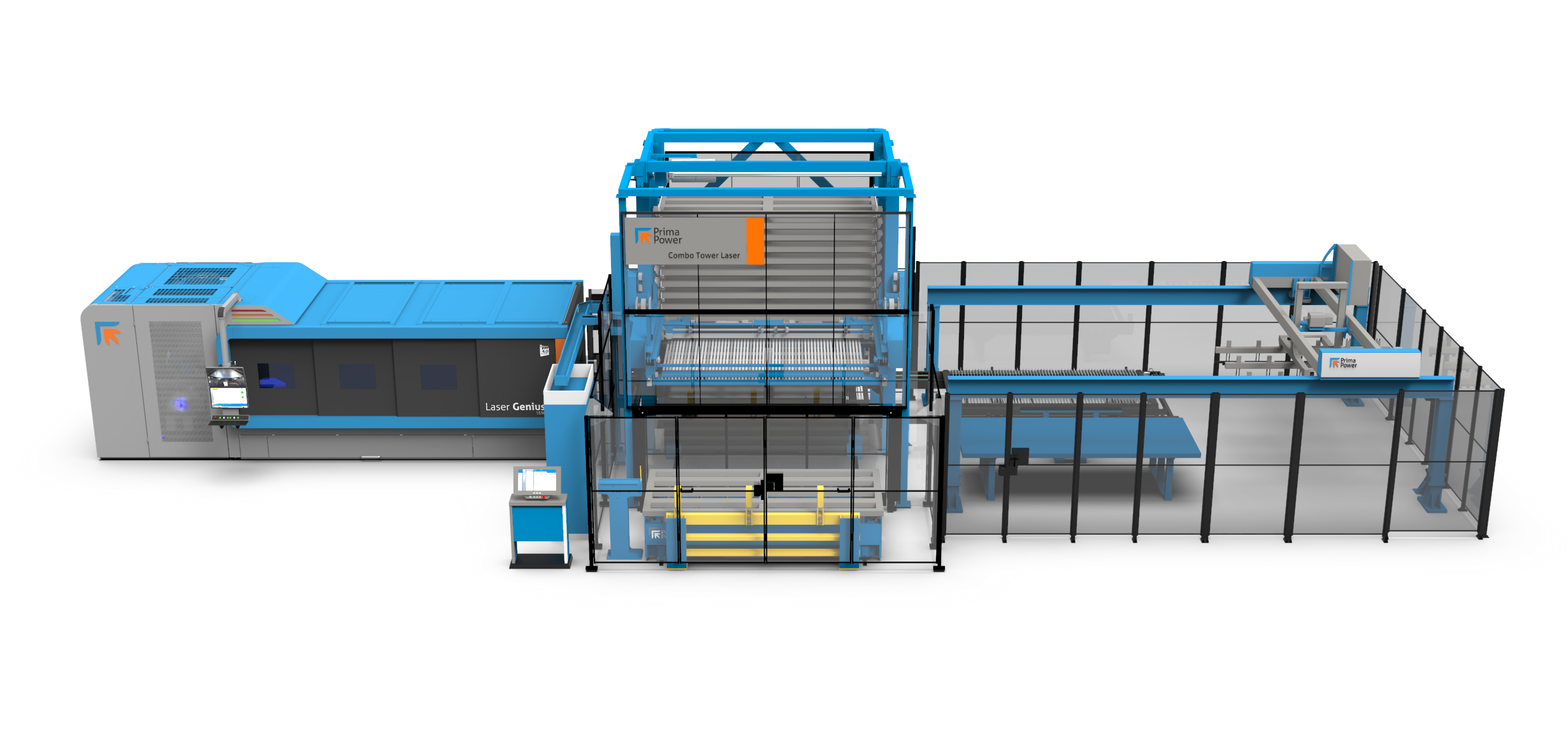

For flexible automatic laser cutting, Prima Power will show the Laser Genius+ with the Combo Tower Laser storage system and the PSR 2D picking and stacking robot. The high dynamics (web speed 180 m/min, acceleration 2.8 g) and precision of this machine enable short cycle times and high cutting quality. With the three sizes 1530, 2040 and 2060 and the wide range of laser powers, it is possible to meet any application requirement.

© Prima Power

Laser quickly installed and combined with robot

Laser Genius+ is a “plug & play” machine with short installation times and a symmetrical and reversible layout that increases ergonomics and ease of integration into any factory. Laser Genius+ comes standard with two 24-inch full HD monitors and a 4K video camera, integrated software modules that simplify processes, and new sensors and artificial intelligence algorithms for advanced monitoring and process control capabilities.

Laser Genius+ can be connected to the wide range of Prima Power automation systems. In Hanover, it is equipped with the intelligent and flexible PSR 2D picking and stacking robot, which offers high stacking accuracy and minimal distances between stacks, automatically enabling optimal use of the stacking area.

Thanks to the modular design of the system and Prima Power’s wide product portfolio, the PSR 2D can be directly connected to the Night Train FMS storage solution and to an automatic sheet metal bending machine, creating an automated production line from the raw sheet to the cut and bent finished product. The compact and flexible storage system “Combo Tower Laser” makes various materials available at any time and can also serve as intermediate storage for finished cut components and skeletons.

Bending and folding with quickly changed tools

The EP Genius 1030 flexible automated bending solution will also be presented at Euroblech, integrated with an automatic die storage system. The high dynamics, precision and reliability of Prima Power servo-electric technology are combined with the advantages of an automatic tool change system. The result is a productive and flexible bending solution that is particularly suitable for small batches. Where the setup time of the machine is calculable and short machining times help the customer to be more competitive.

Some important features of EP-1030 are clamping force of 1050 kilonewtons, bending length of 3060 mm, automatic CNC crowning, 5-axis backgauge and Iris Plus angle control system on CNC arms. The tool magazine holds 32 meters of tools on eight tool holders that move on three axes. A rotating turret allows the tools to be rotated, extending the machining possibilities. The latest generation user interface allows intuitive programming of the workpiece, both on the machine and offline, as well as automatic management of the machine setup.

Simplified programming

Factories are becoming more data-driven to optimize processes, reduce time to market, control the entire value chain, and improve the customer experience. At Euroblech, Prima Power will show its complete range of solutions for intelligent manufacturing. Production management enables, at every level, state-of-the-art production monitoring and diagnostics as well as improved machine programming. In addition to Prima Power’s well-known software solutions, several new products for more efficient and user-friendly programming, simplified machine monitoring and improved manufacturing cost control will be introduced at Euroblech.

Web:

www.primapower.com