AutoForm presents its latest software version, Forming R12. This version offers new possibilities and enhancements for the sheet metal forming process chain, particularly for the feasibility and validation phase.

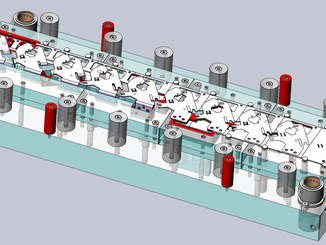

AutoForm Forming R12 offers enhancements and new options that come into play in the feasibility phase of process design. An updated mesh refinement strategy allows a more realistic prediction of the severity, size and number of wrinkles during and at the end of the forming process. The software also allows users to consider not only the maximum press forces, but also their distribution. They can now better determine whether the press is able to close the dies correctly and thus ensure smooth part production. In addition, AutoForm Forming R12 offers various improvements to the solver, such as the option of parallel execution on 16 cores for faster simulation and an increased maximum number of elements, which is particularly helpful for larger sheet metal parts and parts with very fine geometric structures.

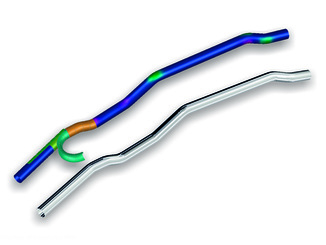

The software also offers various TriboForm enhancements, including extended libraries, which are particularly important for the tryout phase. AutoForm Forming R12 enables users to quickly and easily assess the feasibility of processes. AutoForm Forming R12 also offers new features that are important for the validation phase of process design. Springback compensation is now facilitated by an improved smoothing option that allows users to specifically adjust smoothing factors to achieve the desired surface quality. The enhancements in AutoForm-DieDesignerPlus are also important for process validation, as they greatly facilitate the creation and compensation of high-quality surfaces within the AutoForm environment. The latest version also offers improvements to tool crowning, which is used to compensate for elastic tool deflection. This allows the number of tryout grinds, scrap and press downtime in production to be reduced even further. Dr. Markus Thomma, CMO of the AutoForm Group, explains: “With AutoForm Forming R12, we are offering our users a range of new options and enhancements that are important for the sheet metal forming process chain. By using AutoForm Forming R12, process engineers can achieve better product design, improved and faster process layout and thus reliable long-term performance.”

Web:

www.autoform.com