The first event of BLM Group Germany’s “Gipfelstürmer” Roadshow 2025 took place at the end of March at P & S Metalltechnik in Oederan in Central Saxony. Almost 100 participants from metalworking companies took the opportunity to get to know the processes of a contract manufacturer that plays a pioneering role in this market with its extremely high level of automation. The latest automation step: unloading the BLM Group’s LT Fiber Evo tube laser by robot.

© BLM Group

“For this year’s roadshow, we have chosen the motto ‘Gipfelstürmer’ (‘Summit Striker’) because it is more important than ever for our domestic industry to achieve top performance – in other words, to storm the summits and thus survive in global competition. P & S Metalltechnik is an excellent example of how this is possible today. This is all the more true as we are here at a contract manufacturer that produces a number of different products for industrial companies in many sectors. Today and tomorrow, we are gaining insights into what the future of contract manufacturing in metalworking is likely to look like in general – and we are extremely grateful to P & S Metalltechnik for this opportunity,” said BLM Group Germany Managing Director Andreas Köster, welcoming the visitors to the roadshow. Some had traveled to Oederan from distant parts of Germany.

The guests were amazed

Tours of the production process, which is spread over two levels, took place in the mornings and afternoons on both days. And each time, these guided tours were a real eye-opener for the guests. P & S Metalltechnik uses a total of around 30 industrial robots, which automatically load and unload an almost equal number of machines. The majority of the machines are positioned directly alongside a high-bay warehouse consisting of two complexes.

The materials to be processed are automatically supplied to the machines from a total of 4,500 pallet spaces via storage and retrieval machines and conveyor belts. Where necessary and possible in terms of their dimensions, all semi-finished parts and, depending on the case, finished parts are returned to the high-bay warehouse immediately after production. No operator intervention is required here either.

In addition, P & S Metalltechnik has been using two driverless transport vehicles in its internal logistics for some time for the few material transports that take place between the machines. These autonomous guided vehicles (AGVs) can even move automatically between the two production levels via an elevator. These vehicles are sensitive to dust and dirt on the floor. A challenge that the company solves with a cleaning robot. It also moves autonomously in production.

In short, visitors to the BLM Group Germany’s first “Gipfelstürmer” roadshow event of 2025 were immersed in a scenario at P & S Metalltechnik that seemed futuristic to many of them. “We have implemented a production process here that is unique in contract manufacturing,” says Managing Director Dirk Sittner with conviction. He founded the company, which now employs just over 25 people, 35 years ago. For some years now, he has been running it together with his son-in-law Tobias Oettel, whose main tasks include programming the automated process steps.

© BLM Group

Tube laser cutting with robot unloading

The first stop on the tour was the BLM Group’s LT Fiber Evo tube laser, which has been cutting round tubes, oval tubes, square tubes with cross-sections from 12 x 12 mm, rectangular tubes with side widths of up to 120 x 40 mm and trapezoidal tubes at P & S Metalltechnik since 2023 using its 3 KW fiber laser source. The company also processes open profiles such as C, U and L profiles with this tube laser. It is configured for loading profiles with lengths of up to 6,500 mm and for unloading parts up to 4,500 mm in length.

This machine is also characterized by its flexibility when it comes to materials: With its 2D fibre laser cutting head Tube Cutter, it cuts aluminium and highly reflective metals such as galvanized steel in addition to steel and stainless steel at P & S Metalltechnik. This extremely compact cutting head was developed by the BLM Group together with Precitec specifically for processing tubes. It is manufactured by Precitec exclusively for the Italian group’s tube lasers and is characterized by a particularly long service life thanks to its special technology.

The LT Fiber Evo is the fourth tube laser that P & S Metalltechnik has purchased from the BLM Group. “Just a year ago, we also had an older LT Fiber with a 2 kW fiber source here. The LT Fiber Evo cuts so quickly that we ended up only working with it. We sold the older fiber laser without further ado and equipped the newer machine with the robot,” says Sittner.

This unloads the laser-cut parts into containers or onto storable pallets, which are later transported to the high-bay warehouses by the AGVs and stored here. This automation is currently designed for workpiece lengths of up to 2.40 m. The robot can unload them at three positions and turn them around if necessary. It receives the information required for this from the tube laser. This means that the robot “knows” which tube components with which lengths and cross-sections it will receive from the LT Fiber Evo and how it should place them in which containers.

© BLM Group

Breaking new ground

This automation step brought with it a particular challenge: the unloading of the tube laser must function smoothly. The same applies to the waste: it also has to be reliably discharged – after all, there is no one left to intervene manually in the unattended process step. “We are still in a learning process here. That’s why an operator is currently still monitoring this machine,” reveals Sittner.

P & S Metalltechnik has been programming robots for around 20 years. “We also wrote the software for this automation ourselves, but this time we had to rethink it in many respects,” says Oettel, emphasizing that the automation of the LT Fiber Evo’s unloading process was innovative in the field of tube laser cutting.

The LT Fiber Evo can unload the laser-cut parts both at the front and at the rear. The automation could therefore be installed at the rear. The unloading to the front remained unaffected. As a result, P & S Metalltechnik can manually unload parts that are not suitable for automatic unloading due to their shape or length. A second advantage: should the automation technology fail, the company can continue to produce its tube laser and unload the parts at the front.

The LT Fiber Evo adjusts automatically when changing jobs. As it is now loaded and unloaded in parallel, the time required for production changeovers is significantly reduced: from around 25 minutes to ten minutes. This means that P & S Metalltechnik saves up to 15 minutes per production change. The company uses the machine to produce around 3,000 to 4,000 different parts. Sometimes only small quantities are needed. As a rule, the series sizes are between 100 and 10,000 pieces, or even more, depending on the situation. On some days, there are up to ten order changes. Especially then, the time savings have a positive effect.

Thanks to continuous loading via the bundle loader and automated unloading, the processing time in the tube laser can take up to five seconds longer – which also benefits the energy efficiency of the process and the service life of the technology. Sittner: “The decisive factor is not how quickly the tube laser produces the parts, but how quickly we can get rid of them.”

To date, the LT Fiber has been the BLM Group’s best-selling tube laser worldwide. “It is a ‘bread and butter’ machine that does exactly what it was designed to do with maximum reliability: 2D laser cutting of a wide range of different metal profiles. This means that it also ideally supports the requirements of P & S Metalltechnik,” said Köster.

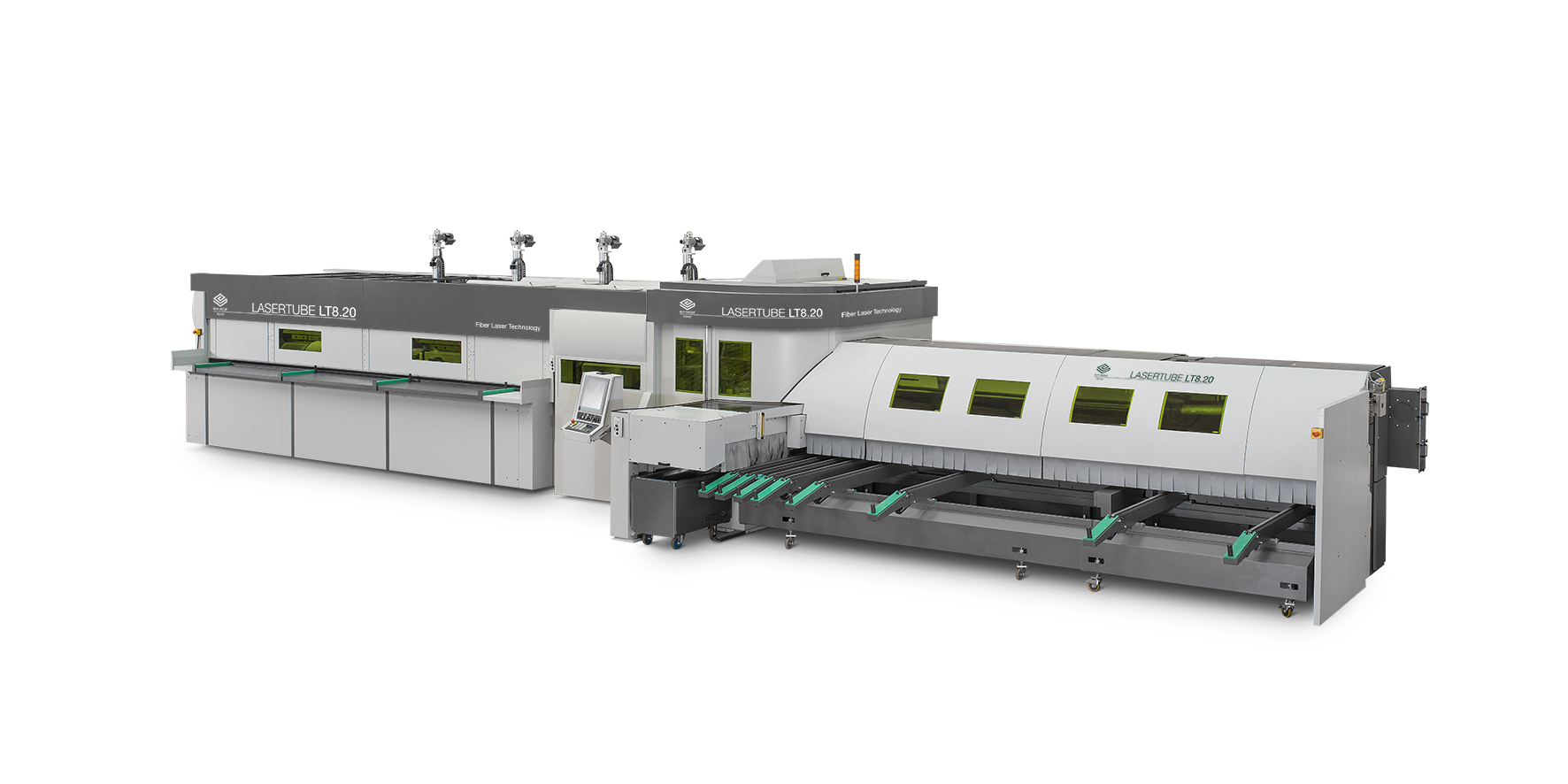

The BLM Group has currently replaced it in its portfolio with two state-of-the-art tube lasers that cover an even wider range of applications: the LTX for 2D laser cutting and the LT6 for both 2D and 3D laser cutting.

© BLM Group

Automation as a factor in competitiveness

Automate what is feasible and sensible – that is Sittner’s principle. “It makes no sense to put people in front of the machines and make them wait until the machines have done their work. We use people in other areas. Especially in the programming of our machines and robots.” Only 15 people work in the two-shift production facility at P & S Metalltechnik.

It is obvious: in this extremely lean, compact and efficient process, which has been thought through down to the last detail, the metalworking company achieves an unusually high per capita turnover. In addition, the high degree of automation – in combination with the company’s high level of vertical integration – guarantees the consistently high quality of the products manufactured. These are all decisive factors in its competitiveness.

P & S Metalltechnik also developed its ERP system itself. With its intelligence, it controls and optimizes the entire production process – from warehouse management to payroll accounting. For example, the materials required for the next day’s production are automatically restocked during the night so that their routes to the machines are minimized and the provision of the materials takes as little time as possible. This means there are no waiting times at the machines.

In order to fully assess the efficiency of P & S Metalltechnik’s integrated production process, it is important to know that the company’s production range currently comprises around 15,000 active assemblies with a number of variants and around 100,000 individual parts. Then there is the raw material. Oettel: “We never have the problem of not being able to find parts.”

Be part of the BLM Group community

Before the BLM Group Germany team’s roadshow took place at P&S Metalltechnik this year, Sittner and Oettel themselves had taken part in various dates in this series of events. “We are convinced of the idea of creating a nationwide network of BLM Group customers within which we can work together and support each other. That’s why we were happy to open up to colleagues and interested parties – and were actually able to establish new business relationships over the past two days,” said Sittner, pleased with the success of the event.

Web:

www.blmgroup.com/de/