The saw manufacturer Meba is pushing ahead with digitalization. This applies both to our own processes and to Meba products. In this way, customers benefit twice over.

As a specialist in remote maintenance, cloud and IIoT as well as monitoring technologies for a quarter of a century, the IIoT, hardware and software specialist Eurogard, just like the metal band saw manufacturer Meba, follows the motto more than ever: Digitization is not an end in itself; digitization must create added value.

At this point, added value does not only mean sales increases and cost reductions, but also product and process enhancements. The added value comes from the consistent penetration and strategic approach in all areas of the company.

This also means that all parties benefit from the application. The machines and systems become more efficient, the statements of the service technicians more well-founded, the business models more comprehensive and digital, the maintenance work more benefit-optimized, sales more efficient and valid, orders faster and automated, and so on.

But how do you achieve the goal of fully exploiting the potential of digitization? Meba’s long experience shows that three things should be understood and applied – regardless of how small or large, how traditional or already digitized the company is:

1. digitization is an expansion of the product range – from product provider to service provider

2. focus on solving human rather than purely technical problems

3. collecting and processing data in a decentralized manner – a necessary driver of innovation

From product provider to service provider

On the path of digitalization, the product range is changing. Digitization is not only a technical enhancement, but leads to a reorientation of the product range. Many companies offer in their history justified so far products, for example machines.

Digitalization is adding a wide range of service products. Understanding this makes it immediately clear that extensive restructuring is needed to make the system functional.

In a 2019 study, the Fraunhofer IAO Stuttgart has derived recommendations for action for small and medium-sized enterprises (SMEs) that want to take the path from product provider to service provider via digital platforms and smart services:

– In order to make the transition from product provider to service provider, it is important to develop your own strategies and business models for using service platforms. Service offerings should be easy to use and easy to understand.

– In order to be able to offer new smart services at all, valid data must be collected, structured and processed.

– Employees must be involved and qualified at an early stage in the transformation process.

– Data protection is also an important success factor here.

© Meba

Solving human problems instead of purely technical ones

A technology alone is not a solution. And in the same way, e-transformation cannot be managed by the IT department alone. IT departments and business units as well as management must work closely together to ensure that the interests of all parties are taken into account and that maximum profit is achieved.

That’s why those responsible need to “get the whole company on board”. Most companies have already taken the first steps towards digitalization. Later, they find that the degree of success of implementation depends not only on technology, but also on systemic and strategic decisions.

It makes particular sense to focus on customer and employee needs when developing future-proof digital strategies and to create a transformation roadmap. This person sets the goals, involves the employees and finds solutions to real problems.

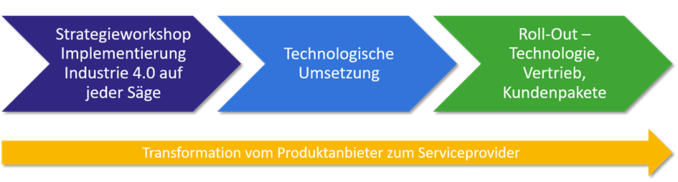

The Meba digitalisation roadmap is an example of how the path to Industry 4.0 can optimally look in practice in a family business that places equal value on tradition and innovation.

At Meba, technological implementation is surrounded by strategic approaches. This puts the focus on people and their needs. This is right and important, because data and technology are only ever a vehicle. The solution to real problems – and thus commercial added value – comes from the consistent optimization of entire processes.

Clear strategy shows the way

The path to digitalization is forward-looking for Meba. A clear strategy was first defined as a basis. Questions had to be answered such as: What can be done? What needs to be done and how can this be evaluated economically? In order to keep the benefit orientation in mind also for digital products and services, the input from customers was very important.

Meba is convinced by the assumption that sooner or later everyone – manufacturers and customers – will have to face the challenge of digitalization, but in a positive sense. Because digitalization offers added value. Meba wants to work these out, convert them into solutions and offer them to its customers.

In order to become sustainably more efficient itself, the company also wants to use digitalisation for its own benefit. This means simplifying processes, speeding them up and increasing quality, with a view to the entire process chain: from the supplier to Meba and to the customer.

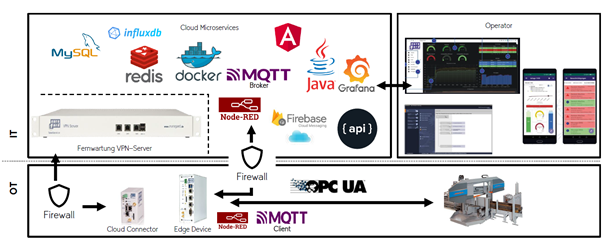

© Eurogard

Easy integration into the existing network

For Meba, the technical particularities lay in the acquisition, transfer and storage as well as the processing of machine data. Under the heading “Mebaconnect”, the company has implemented its first digitalisation projects. They give the customer the possibility to import saw programs created outside the saw via the network or to export operating data of the machine for analysis purposes and optimization.

Customer-specific or supplied programs can be used for this purpose. Remote diagnostics and online support are also already in use and can significantly increase machine availability.

In line with the technical possibilities, Meba has developed service packages in which the diagnostic and online maintenance systems as well as other digital services are sensibly integrated. The packages differ in the level of service and the scope of services included. Digitization now means consistently driving these and new product and service projects forward at all levels.

Collect and process data decentrally

Understanding data as the treasure of the future is a fundamental decision. Whether the data is collected and processed in a cloud or on premise, i.e. on local servers, can be customized according to customer requirements. Capturing them is indispensable if you want to think in terms of future systems, digitization, and ultimately machine learning and AI.

However, an IIoT platform is not an inexpensive data center, but a cornerstone for smart services with its specially adapted range of functions. The continuous networking of machines and sensors offers the possibility for completely new business models.

However, data collection and processing is a means and not an end in itself. It is critical to business initiatives, efficiency, innovation and growth. For example, applications on an IIoT platform make it possible to test prototypes faster or base business decisions on real-time or historical data.

There is also huge potential in the combination of advanced technologies, such as machine learning, and the gigantic number of devices connected to the Internet of Things today and in the future.

Here, Eurogard offers a very broad technological basis with its own cloud connectors and edge devices as well as its own IIoT platform “machine to value”, which is also hosted in Germany, including a wide range of KPI visualization options and VPN software.

Advantages of investing in digital future systems

– Generate knowledge: Collect, visualize, evaluate field data

– Develop new digital business models

– Optimize remote maintenance

– Gain of knowledge: Conditions of use of the products

– Failure analyses: Understanding of product weaknesses

– Consideration of historical data

– Quality improvement: new ways of product evaluation

– Basis for Predictive Maintenance, Machine Learning, AI

Meba metal band sawing machines GmbH

Meba is a specialist for metal band sawing machines and has developed since its foundation in 1958 from an artisan-run business into an internationally active industrial company. Today, Meba offers its customers from trade, metal and steel construction as well as large-scale and heavy industry a complete product range of user-oriented individual saws, complete systems with material handling and length measuring systems in almost all degrees of automation as well as networked sawing solutions and the associated services.

The company’s services also include being there for the customer from the initial consultation, through planning, design, implementation of the project, commissioning, spare parts service, right up to long-term support for the sawing solutions. Even in the digital world, Meba keeps an eye on the benefit orientation – because digitalization should bring something to everyone.

Eurogard

Long-term, trusting and satisfied customer relationships are the core elements of the self-image of those responsible at Eurogard. For more than 25 years, they have been shaping the topic of digitization to fit customers as closely as possible. In addition to a wide range of mechanical and plant engineering companies, these also include the pharmaceutical and biotech sectors.

The employees’ deep technical understanding of everything from hardware to PLC technology to Big Data applications enables Eurogard to generate added value for a broad customer base. With certified PMP-PMI project managers, the company also offers smooth, full-service project management: consulting, planning, execution, service, commissioning, qualification and training – all from a single source.