Under the motto “Future Forming Technology”, Wafios will participate as usual with two booths in the trade fair duo Wire & Tube. The focus is on forward-looking high-speed technologies that enable productivity leaps in manufacturing, as well as pioneering production processes and automation solutions. New fields of application and digital services for intelligent maintenance round off the program.

Minimum cycle times with maximum flexibility and modularity

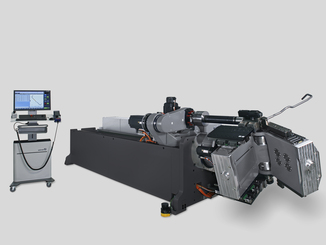

A new transfer and bending unit parallelizes forming operations across several stations and significantly minimizes cycle times per component. The stations can be modularly adapted for a wide range of applications and interlinked with corresponding spring, wire or tube bending machines. The transfer and bending unit will be demonstrated at Wire in conjunction with the FUL 26+ CNC spring coiling machine for the production of stem eye springs, which will be increasingly used by users in the automotive and e-mobility sectors.

© Wafios

Productivity leaps with high-speed technology for springs and wire bending parts

The 4speed technology celebrates its international world premiere. At Wafios, the designation 4speed has recently come to stand for machine developments that are designed for maximum production performance. In their final configuration, the new FUL 26+ 4speed and FUL 36+ 4speed are the fastest spring coiling machines in the world for the production of compression springs with a wire feed speed of up to 600 m/min.

The new high-speed wire bending machines are making their international trade show debut in Düsseldorf and are expected to set new standards in terms of speed, productivity and quality. The Wafios BM 43 HS will be presented as a stand-alone solution, and the BM 36 HS will be presented for the first time with a handling robot that is fully integrated into the Wafios WPS 3.2 EasyWay control system.

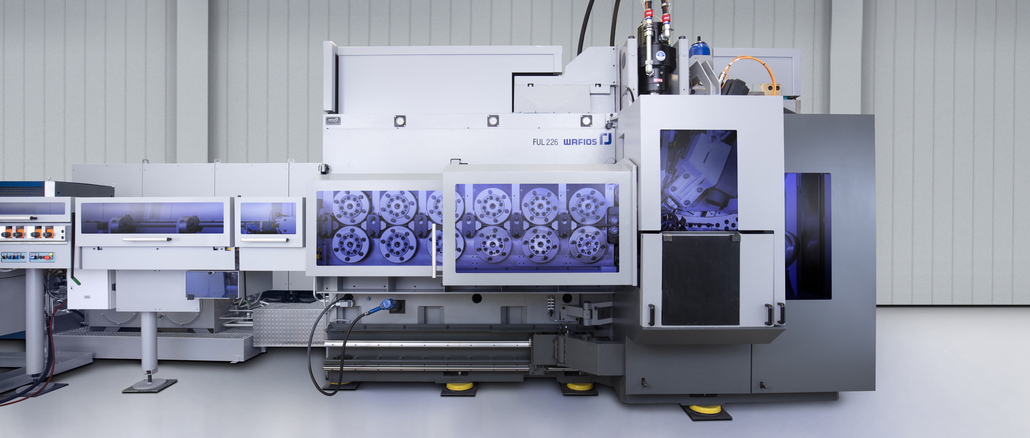

Cold forming up to 22mm high tensile spring steel wire

With the new FUL 226, 22-mm wire can be cold formed at 2,000 N/mm² for the first time. All the familiar advantages of cold forming on FUL machines, such as greater geometrical freedom, use of camera technology and flexible programming, now also come into play in the upper wire diameter range. New market fields such as applications in the e-mobility sector and for hybrid vehicles and light trucks are being developed. In Düsseldorf, the 40-ton spring coiling machine is presented digitally.

Automated manufacturing solutions integrated in one programming system

Wafios will present new automation solutions with loading equipment, feeding systems and cell solutions in all application fields.

The WPS 3.2 EasyWay programming system goes a decisive step further here and fully integrates previously independent systems such as handling robots or additional machining units into the machine control system.

Demonstrated on the BM 60 wire bending machine interlinked with the RU 60 servo-electric forming press from Wafios Tube Automation. With 600 KN forming force and newly developed tooling system, the combination offers new possibilities for the production of wire bending parts with end machining.

© Wafios

Future technology e-mobility

The FMU 40 E with handling robot fully integrated in the control system for the production of hairpins for stator manufacturing will be presented. Other applications such as busbars and cooling cables from the e-mobility sector can be found at all Wafios booths in Düsseldorf.

Maintenance intelligently under control

For the trade fair premiere, Wafios will present the intelligent maintenance software “Connectavo – the digital assistant for machines and plants”.

Furthermore, Wafios will for the first time showcase its IoT Suite, a unified, open system for the complete networking of machines and plants.

The largest trade show program in the company’s history

The Wafios G450 spring end grinding machine with new robot feed is a smart machine with connection to the iQsmartgrind technology database and new loading device. The Wafios SNA 26 for the production of wave springs and rings closes the gap in the working range between the SNA 16 and SNA 36.

After the successful market launch of the legendary ZO series in 2021, Wafios presents the long-awaited expansion for small dimensions with the ZO 16.

The Wafios BMS 50 multi-head wire bending machine up to 10 mm wire diameter will celebrate its trade show premiere. The BMS is exhibited with CNC chamfering device for chamfering the bar ends on both sides.

From the straightening sector, the Wafios R 36 smooth steel straightener with iQmstraight straightness measurement is coming to the show – with a new adjustable rotor, for automatic readjustment in the case of bars outside the straightness tolerance.

© Wafios

Service offerings and innovative tool solutions

The new retrofit solution for the classic FMU 2 is presented for the first time. In the field of wire bending, Wafios presents the new MBS modular tool set for a wide range of applications. In the springs area, the focus is on new coating solutions for the tools of the FUL series.

PTS “Pneumatic Transport System

The new PTS development ensures resource-saving parts output, effectively avoiding the mixing of parts during product changes. The parts come out of the machine position-oriented and almost oil-free, with good and bad parts being automatically separated by a sorting switch.

Specialist for thread and profile rolling machines with digital machine assistant

With iQ-Setup Assist, the simple and product-specific setup aid at the push of a button, and iQ-OEE Monitor, the machine data acquisition assistant for process evaluation, EWMenn will be showing the AF 141 high-performance thread and profile rolling machine with flat dies.

Hall 10 – Booth F 22/40 and Hall 5 Booth A21/A22

Web:

www.wafios.com