The focus of Wafios’ dual trade show appearance at Tube and Wire will be on forward-looking high-speed technologies that enable leaps in manufacturing productivity, as well as “revolutionary” production processes and automation solutions. Numerous machine premieres from all Wafios product ranges round off the program.

Everything that Wafios has developed recently can be experienced on more than 1600 m² of exhibition space from June 20 to 24 at the Wafios booths in Hall 10 F22/F40 (Wire) and in Hall 5 A21/A22 (Tube).

World premiere of the Wafios HotBend 35 for bending plastic pipes

The HotBend 35 is based on a versatile and flexible machine concept with a future-oriented production process for bending plastic pipes with outer diameters of up to 35 mm. It enables bending of straight plastic pipes in the 3D bending process, comparable to a classic pipe bending machine. In this process, the sheet area is heated with hot air in the heating system (patent pending) and then formed conventionally using the rotary draw bending process. The proven Twister² technology is used to support the tube geometry. During the bending process, the handling robot dynamically supports the plastic tube and stabilizes it during the cooling process. The robot movements are determined automatically by the Wafios WPS 3.2 programming system. Accordingly, even small series can be produced flexibly and economically.

With the HotBend 35, Wafios is responding to the increasing demand in the automotive sector for weight-optimized corrugated tubes, fluid and fuel lines. The machine can also be used for new applications in the e-mobility sector, for example in battery temperature control.

© Wafios

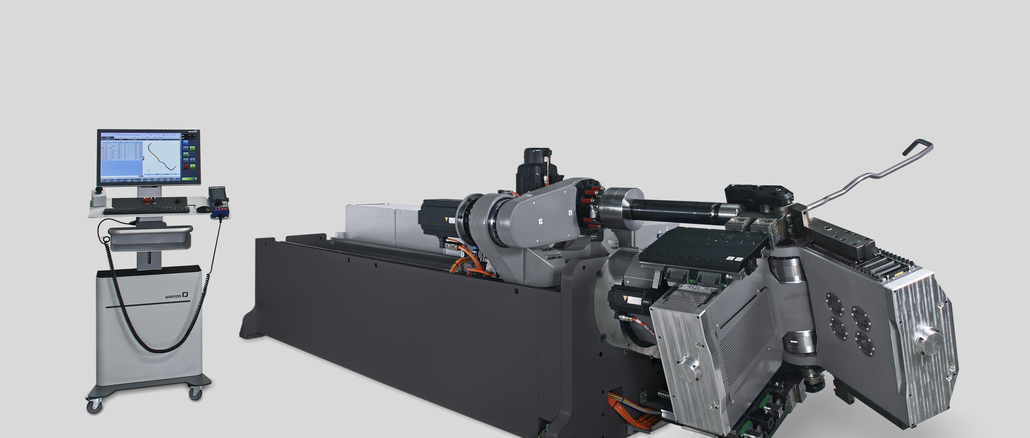

Wafios Twister² RL 25 Right-left tube bending machine up to 25 mm diameter and 4,000 mm length

Extension of the Twister² product family in the upper working range. The robotic bending line combines flexible tube handling and the bending process in one complete system. This also allows components with preassembled fittings on both sides, such as those found on hydraulic lines with hose segments, to be bent efficiently by sequentially machining both sides of the tube. The use of rotary tensile bending tools with several levels also allows the use of special and forming tools for short clamping lengths.

RST 28 high-speed tube bending machine celebrates international trade show premiere

The latest machine development from Wafios in the field of stabilizer production ensures top values in terms of output and service life. The RST 28 features patented kinematics and can reduce non-productive time during bending by 70 percent. According to Wafios, this is the first tube bending machine that is 100 percent tailored to the requirements from the cold forming sector of prehardened stabilizers with complex geometries. The high bending speed with simultaneous high forming forces also make the machine very attractive for other tube applications such as seat structural parts made of dual-phase steel.

© Wafios

Maximum flexibility in tube end forming with the new RU 12 compact

End forming with short cycle times – flexibly applicable, issued as stand-alone and cell solution. Newly developed compact forming machine for individual tube ends. The horizontal mold concept ensures high accessibility, suitable for curved and short workpieces and optimized feeding and handling systems. The RU 12 allows the use of standard tool holders as well as the “Easy Lock System” to reduce setup time. Applications include fluid lines such as oil, fuel or hydraulic pipes from the automotive industry, pipe forming in medical technology or refrigeration and air conditioning technology.

Other machines from the current tube bending machine program

The Wafios RBV 60 R must not be missing from the trade show program. Successfully established in the market for years, the bending machine convinces with maximum dynamics, rigidity and highest precision of machine body and bending head. The modular machine concept is adaptable to a wide range of applications and can be fully integrated into automated solutions.

Developed for the production of complex bent parts with end machining and partly prefabricated tubes, the Wafios BMZ series sets standards on the market. Highest output rates with superior, precise technology and perfect machine handling are hallmarks of the series.

Flexible, fast, precise with short set-up times are features of the price-oriented RB 20 set-up bending machine from WTA, for classic fields of application in automotive, refrigeration and air conditioning technology.

Wafios on the Wire

Minimum cycle times with maximum flexibility and modularity, world premiere of a new transfer and bending technology, a flexible system for reducing cycle times by carrying out different process steps in parallel, cold forming of maximum 22 mm thick high-strength spring steel wire, international world premieres – these are some of the highlights at Wafios’ booth in Hall 10.

Automated manufacturing solutions integrated in one programming system

Wafios will present new automation solutions with loading equipment, feeding systems and cell solutions in all application fields. The WPS 3.2 EasyWay programming system goes a decisive step further here and fully integrates previously independent systems such as handling robots or further processing units into the machine control system – presented on the BM 60 wire bending machine, interlinked with the RU 60 servo-electric forming press from Wafios Tube Automation. With 600 kN forming force and newly developed tooling system, the combination offers new possibilities for the production of wire bending parts with end machining.

E-mobility on the Wire

The FMU 40 E with handling robot fully integrated in the control system for the production of hairpins for stator manufacturing will be presented. Other applications such as busbars and cooling cables from the e-mobility sector can be found at all Wafios booths in Düsseldorf.

Maintenance under intelligent control – “Digital Services” from Wafios

For the trade fair premiere, Wafios will present the intelligent maintenance software “Connectavo – the digital assistant for machines and plants”.

Furthermore, Wafios will for the first time showcase its IoT Suite, a unified, open system for the complete networking of machines and plants.

Attractive service offers and innovative tooling solutions, such as newly developed tooling technology especially for bending plastic pipes, demonstrated on the Wafios HotBend 35, round off the versatile trade show program.

Web:

www.wafios.com