The latest innovations, exciting discussions and a varied supporting program: the Innovation Days at Wafios’ headquarters in Reutlingen are entering their fourth round in 2025. The event kicks off on May 7, 2025.

Around 24 exhibition machines from the entire product range will be demonstrating new developments and best practices for the wire and tube processing industry in live operation. Numerous co-exhibitors will also be presenting their solutions for the industry. Visitors will have the opportunity to experience the latest innovations live on site and engage in direct discussions. A supporting program with presentations on innovations and technology rounds off the Wafios Innovation Days.

© Wafios

Modular and highly flexible spring production

The new Multi-FMU 32 is a modular machine for the production of extension springs with eyelets. The Multi-FMU 32 follows the modular system of the BQ 10, the transfer bending machine for bent wire parts. Once the spring body has been produced using either the coiling or winding process, further bending stations follow to produce the eyelets. These can be arranged flexibly depending on the spring geometry and customer requirements.

A transfer system moves the springs from station to station. At the Innovation Days, the Multi-FMU 32 will be demonstrating the production of eyelets, where the tension spring body is wound over the mandrel. One advantage of the modular design is the great flexibility of the machine. The number and function of the work stations is freely configurable and can be adapted according to requirements. In addition to tension springs with shank and hook eyelets, springs with German and English eyelets can also be produced on the machine.

“Over the last 20 years, the FMU has established itself as the standard for the flexible production of torsion springs. The Multi-FMU combines the high flexibility and simple programming of the FMU with the high production output of classic mechanical multi-station machines, such as the well-known FSO 3 or ASF/BSF. In the future, a further variant will follow as a successor to the ZO 4 / ZO 41 and ZO 42 as well as the ZOS 3 / 4 and ASF 4 / BSF 4-S,” says Dr. Uwe-Peter Weigmann, Spokesman of the Executive Board at Wafios.

© Wafios

High quantities in the production of bent parts from wire and tube

Another modular machine is the BQ 10. It is a CNC transfer bending machine for wire diameters from 3 to 10 mm. The machine can process round and profiled wire. The machine on display offers modules for bending, forming, flattening and punching at four stations. In addition, a thread roller can be integrated between the feed module and the wall. Perfect for the production of an entire family of components. “With the help of the different stations, several work steps run simultaneously. The parallelization of production leads to a high output rate,” says Jörg Eisele, CEO at Wafios. The modular, freely programmable transport system is patent-pending and will be demonstrated at the Innovation Days with five individual CNC transfer modules.

These can each be programmed individually and independently of each other. The stations can be offset from their original position. Thanks to the programmable CNC axes, the single transfer system enables quick adjustment of the new position, even in existing programs.

Production of springs with German and English eyelets

While the Multi-FMU 32 will demonstrate the production of tension springs with eyelets, the two FMU machines will show the production of springs with German and English eyelets. At the Innovation Days, the application of the ModularLoopConcept, a flexible tool concept for the production of eyelets, will be demonstrated on two machine sizes, the FMU 20+ and the FMU 50+.

Intelligent sorting device

The new sorting device uses the FUL series to demonstrate what a modern 3-channel sorting device can achieve. The sorting device is motor-driven and electrically controlled. Maximum reliability of the sorting process is achieved by monitoring the position of the flaps. During the correct sorting process, the falling behavior of the springs is monitored by sensors. This increases production reliability by preventing springs from jamming or an incorrectly positioned flap. The automatic setting of the delay time depending on the drop time also ensures a convenient and reliable set-up process.

© Wafios

Speed mode for compression springs

The FUL 76 can automatically adjust the axis parameters depending on the spring specification. The spring coiling machine automatically optimizes the feed speed based on the wire diameter, coiling ratio and tensile strength, depending on whether more feed speed is required for small wire diameters, for example, or maximum force for large wire diameters. As a result, the output rate can be increased by up to 13 percent with small outer spring diameters or large coiling ratios using dynamic axis parameters. The machine switches into “speed mode”, so to speak.

Simply set up new parts

At Wire 2024, Wafios presented the assisted machines, such as the assisted wire bending machine BM 36 HS, for the first time. “We received very positive feedback from the market. That showed us that we were on the right track,” recalls Dr. Weigmann.

A new requirement is the storage of customer-specific assistance sequences. The result is the new Wafios Assistant, which is now celebrating its world premiere at the Innovation Days. The Wafios Assistant guides the operator through the setup of new parts and helps inexperienced users with instructions, images and videos. This also makes it much easier to set up complex parts.

In addition to the set-up sequences provided by Wafios, operators now have the option of creating their own individual assistance sequences to support the uniform set-up of machines in the company. Internal know-how can be easily multiplied with the Wafios Assistant. This ensures standardized programming processes. This improves quality and production reliability, while at the same time ensuring that in-house expertise does not leave the company. The individual assistance processes remain within the company. “We are thus fulfilling a long-standing requirement of our customers to protect their know-how, while at the same time making it easier to share knowledge within the company,” says Dr. Weigmann.

Continuous quality improvement in straightening

At the Innovation Days, the new bar position detection option in conjunction with EBF end machining will be presented on the R 36. Length deviations can be detected directly on the product, especially for bars with chamfered ends.

The EBF end machining unit is equipped with sensors that are attached to both end machining units and optically detect the position of the bar ends during clamping. Based on these positions, the control unit calculates the required feed values for the desired chamfers and transfers these to the corresponding feed speeds of the chamfering spindles. This compensates for length differences caused by temperature or cutting tolerances and produces continuous chamfers. This leads to a continuous improvement in quality, reliable chamfering, shorter set-up times and fewer rejects.

Wide range of variants in the production of conductor rails

Whether in purely electric or hybrid vehicles, busbars are a key technology in electromobility today. The requirements vary enormously. A small, maneuverable car with little space, or busbars for a truck with large conductor cross-sections. Wafios machines can cover a wide range of variants. At the Innovation Days, three different machine concepts will be presented that are adapted to the needs of manufacturers.

Depending on the material specification and the cross-section ratio, the BMF 90 busbar machine can process material up to a maximum of 200 mm². The specially designed and patented bending tool allows the smallest bending radii with minimal bending distances while maintaining the highest quality at all times. Mechanical stripping can also be integrated into the BMF 90. Mechanical stripping is a cost-effective alternative to the CO2 laser and helps to reduce cycle times by 40 percent or more.

For long, three-dimensional busbars with asymmetrical geometries, Wafios is presenting the new BTF 90, a pioneering machine concept, as a prototype for the first time. It combines the familiar technology of the double-head wire bending machine from the BT series with the BMF 90. The BTF extends the possibilities of BMF technology from small and medium-sized to long busbars for cross-sections of up to 200 mm². The BTF also offers the option of processing pre-assembled material from a magazine. It can be adapted to suit individual requirements and ranges from the production of prototypes to series production. According to Wafios, one highlight is the new transport system with gripper feed, which will be presented for the first time at the Innovation Days.

The Twister² opens up new possibilities in the production of long busbars with large conductor cross-sections of up to 400 mm². The tools from the tube area prevent surface deformation and at the same time provide sufficient bending torque to bend busbars over both the long and the short profile side. The large portfolio of machines for the production of busbars allows Wafios to meet customer-specific requirements such as short bending distances, long lengths, different cross-sections, high output rates, various stripping processes and the integration of additional process steps.

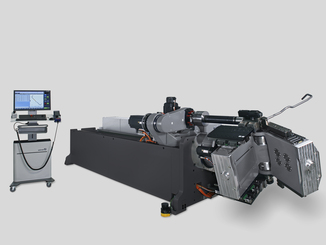

New loading concept and support when changing tools

Numerous innovations will also be presented in the classic tube bending sector. These include the TopBend 35, a fully-fledged right-left tube bending machine for the market-oriented entry level. It offers a very high working speed thanks to a performance-optimized design, maximum energy efficiency thanks to state-of-the-art drive technology and a modular machine concept.

As a cost-effective variant, the TopBend is also available with only one bending direction as an Eco version. The second bending direction can be retrofitted at any time. The machine will be presented for the first time at the Wafios Innovation Days with the new inclined magazine with CNC loading device.

The newly developed loading concept consists of an inclined magazine and an additional CNC loading arm system, which is positioned between the magazine and the bending machine. One advantage of the system is that the pick-up position in the rear or front area can be freely selected. As the pipe material is already provided to the bending machine within the auxiliary time, this also results in optimized cycle times.

The TopBend 100 was developed for large pipe diameters. It is a tube bending machine for tube diameters up to 100 x 4 mm and can be flexibly configured. At the trade fair, the flexible configuration will be visualized with a new digital concept.

The Wafios programming software WPS 3.2 EasyWay is constantly evolving. A new software feature is the automatic compensation of radius deviations. The software calculates the radius increases that occur during bending based on the material data and adjusts the geometry of the component. This enables the operator to achieve a gaugeable good part more quickly.

Background

Wafios develops, designs and manufactures sophisticated special machines for the wire and tube processing industry as well as for cold forming. The company is one of the leading suppliers in this field. Over 130 years of experience speak for quality and innovation. The product range comprises more than 130 machine types. Equipped with state-of-the-art software, artificial intelligence and IoT, Wafios machines optimize piece output and quality and improve the set-up process. 60 percent of customers come from the automotive and supplier industry, with a growing share in e-mobility. Other important sectors include mining, construction, electrical engineering, medical technology, household appliances, agriculture and the furniture industry. The export share is over 60 percent.

Today, Wafios is a group of companies with Wafios AG in Reutlingen as the parent company and several locations in Germany (Reutlingen, Marktredwitz, Wuppertal, Berlin, Simonswald), in France (Ecuelles), in Portugal (Maia), in America (Branford/USA, Mokena/USA, Querétaro/Mexico, São Paulo/Brazil) and in Asia (Shanghai/China, Zhangjiagang/China) to support customers locally. Under the Connectavo brand, Wafios is expanding its core business and developing cross-industry software solutions for the maintenance of machinery, building technology, vehicle fleets and other technical equipment, for example.