On 180 m², the Cidan Group will present machine and software solutions for sheet metal working companies from trade and industry in Stuttgart.

The TD double bender from Thalmann will be shown with two automation units that can be integrated in a modular way: with automatic lateral sheet feeding and with automatic sheet turning unit. In addition, visitors to Blechexpo can expect a premiere that is not yet to be revealed. There is talk of side loading, and this innovation is designed to make side loading of the machine even faster, more flexible and more efficient.

The maximum bending capacity of the TD double benders extends up to 2.50 mm (at 400 N/mm²). Between 3.2 and 12.0 m are the standard working lengths. Other working lengths can be custom made upon request.

© Staffan Åkervall

New coil lines for smaller and larger operations

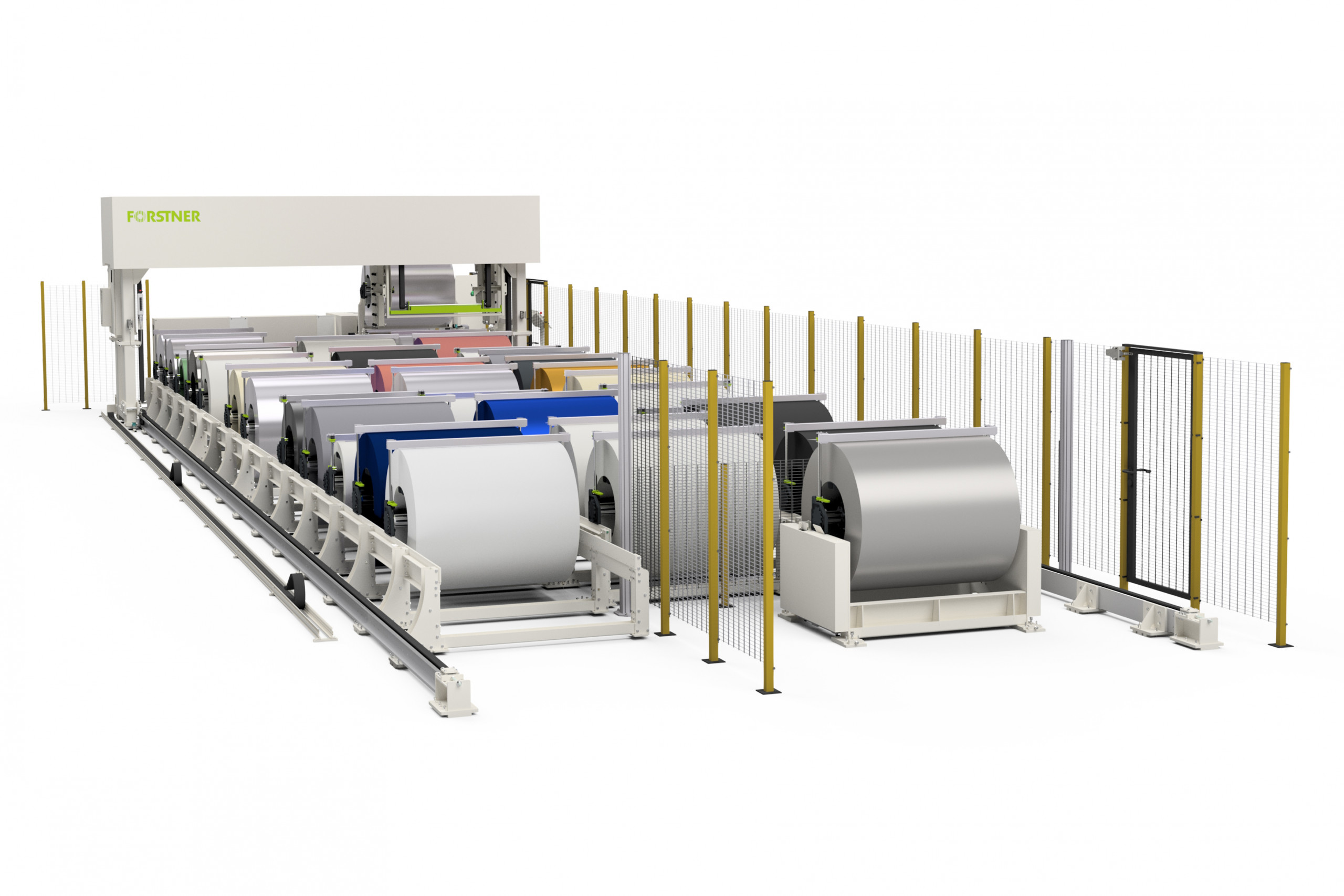

Forstner will show two coil lines. One is the Forstner Nuslit Cut in combination with a manual unwind tower. The manual unwind tower makes it possible to store and unwind two coils on top of each other in the space previously needed for one coil. Each decoiler can carry a coil weighing two tons and 1,250 mm wide. The towers can be easily loaded by crane or forklift, allowing fast coil changes with minimized risk of material damage. The Nuslit Cut is an economical solution and good entry-level machine for typical, smaller sheet metal stores, according to Cidan. It is a slitting and cut-to-length line equipped with roller shears and automatic slitting knife adjustment.

The other machine Forstner is showing is called Forstner Nuslit Straight Procut Print. It is virtually the fully equipped version for “advanced” plumbers and facade builders. This model also has an integrated straightener plus a labeler for scanning QR codes. In addition, waste optimization is also possible thanks to the sectional roller shear.

Three new machines

Cidan shows three machines. One is the Rapido 41 SSM guillotine shear. Designed to meet the rigorous demands of modern sheet metal working, it aims to set new standards in efficiency, precision and versatility. It is also designed to process delicate materials such as stainless steel, copper and aluminum with unparalleled accuracy and care. Cidan Rapido SSM (Stacking Sensitive Material) is a new cutting and stacking system that speeds up the guillotine shear and never leaves scratches or dog-ears, according to Cidan. With a width of 4 meters, it is able to stack large sheets with a depth of more than 1000 mm, increasing production without compromising quality.

The staff only sets the backgauge dimensions and the number of blanks. The sheet support retracts in a flash and the cut material drops gently onto the mobile material cart (option) below, where up to 24 cut panels per minute can be stacked. The material trolley can be loaded with 700 kg. For example, those producing sheets 125 to 410 mm wide can stack up to 90 mm high. For sheet widths greater than 410 mm, only up to a height of 40 mm.

Together with the CutLink control, Cidan says the customer gets “a real cutting and stacking giant” that can be programmed for different backgauge settings with the desired quantity, while always stacking the panels neatly on the material cart.

“As part of our ongoing commitment to innovation, quality and sustainability, we have developed the Rapido 41 SSM guillotine shear to not only meet the challenges of today, but also to anticipate those of tomorrow,” says Petter Hjelmqvist, CEO of Cidan Machinery Group. “We believe this machine represents a leap forward in sheet metal processing technology.”

The second Cidan machine at Blechexpo is the Cidan F32 Xspace swing bending machine. According to the manufacturer, the Cidan F is fast, user-friendly and reliable. The new design is robust, with welded side stands, and extra strong lower and bending beam. The generous opening width of 150 mm allows more flexibility. The novel spring steel fingers combined with what Cidan claims is the narrowest bending rail on the market enable precise processing and offer great flexibility for even the smallest bends (under 3 mm). The bending beam is very rigid and stable, but also small enough that the operator does not have to step back when bending.

The new Nulink control system is presented on this machine. Nulink is said to be a “safe and reliable way to perfect parts,” even in the hands of an inexperienced machine operator. The user-friendly interface with interactive graphic instructions guides the operator through each step of the process, from positioning to turning and flipping to finishing the bent part. With this intuitive approach, even the production of complex elements is child’s play, he says.

Nulink securely stores production data in a central database, ensuring easy access and streamlined operations. In addition, the online platform provides a background service for fast and efficient integration and maintenance of the system.

The third Cidan machine is called Forma Z.

The Forma Z is the most flexible and versatile swing bending machine in the Cidan portfolio. The Forma Z can be used to bend both upwards and downwards. This eliminates the need to turn the material, allowing fast bending of complex sheets by a single operator. The rotation of the combi upper beam between two mold assemblies and the special geometry provide a large working area. Automatic tool locking is fast and has features that make tool changing very ergonomic. The bending beam has automatic crowning, automatic bending center adjustment and automatic sheet thickness adjustment, ensuring good bending quality at all sheet thicknesses and over the entire bending length. The large number of vacuum grippers holds the part stably at any point of the backgauge – large sheets as well as small, single pieces as well as multiple pieces. The backgauge is available in many styles, giving the customer a choice of how to operate the machine and control the routing of sheets to and from the machine. In addition, the Forma Z is fast, the supplier says, allowing it to produce more in less time.

Web:

cidanmachinery.com

BlechExpo:

Hall 1, Booth 1403