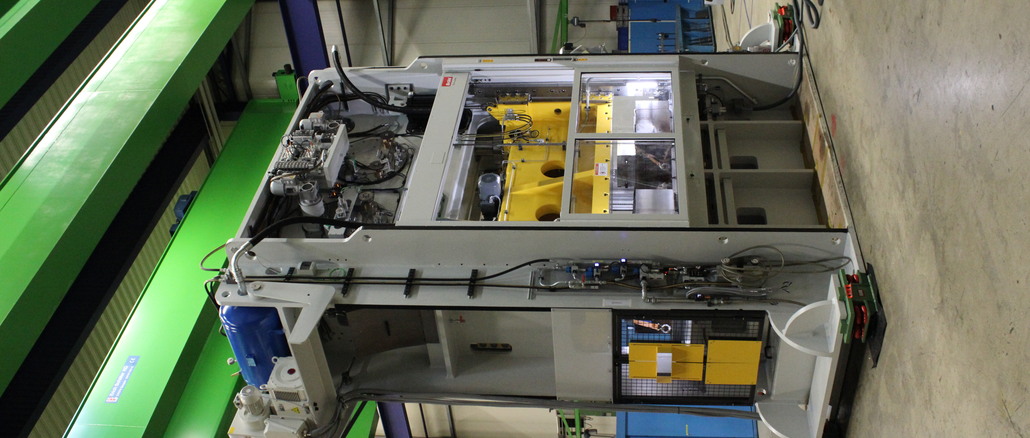

At the in-house exhibition at Gräbener Pressensyteme, visitors watch how a knuckle-joint press embosses bipolar plates for fuel cells.

Göppingen/Netphen, December 6, 2022 – Hydrogen is considered the energy carrier of the future. The technology is already there: The components for fuel cells, which transform the gas into water and emit electricity as a result, are produced on Schuler lines. The so-called bipolar plates are stamped on a TMK 2-400 knuckle-joint press, for example, as visitors to Schuler’s in-house exhibition at Gräbener Pressensysteme in Netphen-Werthenbach near Siegen could now experience.

These are high precision formed stainless steel plates which are welded in pairs. 300 to 400 bipolar plates make up a fuel cell. Thanks to its special mechanical properties, the knuckle-joint press on display is ideally suited for embossing bipolar plates. At the same time, it is also prepared for Industry 4.0 thanks to various sensors: Via certain applications from Schuler’s “Digital Suite,” the cooling and lubrication circuits as well as the temperatures of the line, among other things, can be monitored and analyzed from any mobile device.

The company’s subsidiary Gräbener Pressensysteme in Netphen-Werthenbach is not only a production location for high-performance presses with knuckle-joint drives, but also home to “Schuler Service North-West”, which offers the entire range of services for safety and line availability to the many customers in the extended region – from quick help around the clock, spare parts, and repairs to maintenance, used presses, and digital solutions. Modernizations, such as control system upgrades, are also part of the scope of supply.

Internet

www.schulergroup.com/fuel-cell